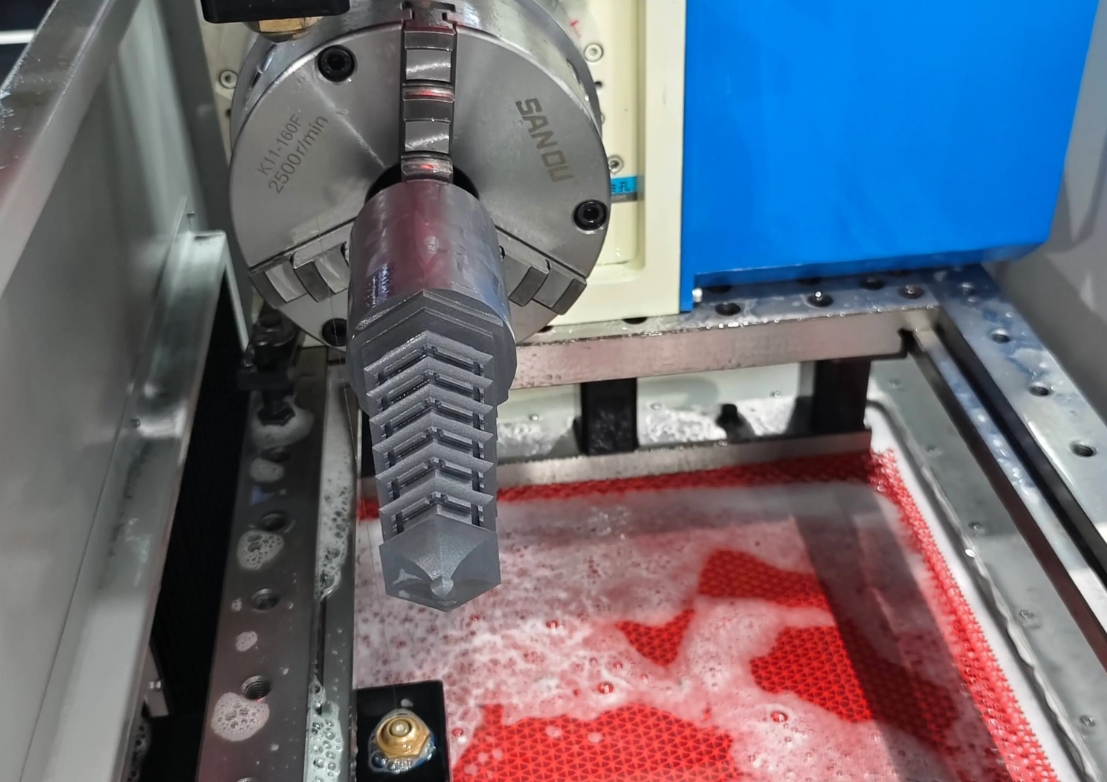

Wire-Cut Machining

Wire cutting is a commonly used metal processing technology that uses high temperature and high pressure electric spark discharge to cut metal materials into the required shape and size. Wire cutting has the advantages of high precision, high cutting efficiency, and good surface finish.

HXC Wire-Cut Machining

Wire-Cut

Wire cutting is a kind of electric machining machine tool, its basic working principle is to use continuous moving thin metal wire (called electrode wire) as electrode, pulse spark discharge on the workpiece to corrode metal, cutting molding.

Low Speed Wire Cut

Slow Wire

Slow wire is a kind of processing machine tool that uses continuous moving fine metal wire (called electrode wire) as electrode to carry out pulse spark discharge to corrode metal and cut and form the workpiece. The phenomenon of loose contact light pressure discharge between the on-line electrode and the workpiece during slow wire processing.

Middle speed wire-cut machine

Neutral filament

Wire walking is a kind of of EDM wire-cutting machine tool. It can use continuously moving molybdenum wire (called electrode wire) as electrode to carry out pulsed spark discharge to remove metal and cut the workpiece.

High speed wire-walking EDM wire-cutting machine

WEDM-HS

Fast wire is a kind of EDM wire cutting, also called high-speed EDM wire cutting machine (WEDM-HS), its electrode wire high-speed reciprocating movement, molybdenum wire speed is 8 ~ 10m/s adjustable, molybdenum wire can be reused, processing speed is fast and convenient (its accuracy is 0.05~0.08mm).