Advantages of CNC machining difficult parts

Fast delivery: Various models of CNC machine tools can realize multiple processes (such as drilling and tapping) at the same time, multiple surface treatments, save processing cycles, HXC produces high-precision parts in 3 working days.

High precision: With multiple imported CNC processing equipment, the accuracy can reach a tolerance of +/-0.05-0.01mm.

Unlimited quantity: Whether it is 1 piece of proofing or 1,000 pieces of small batch customization, it can be met.

Unlimited materials: You can choose various metal materials and plastic materials sold on the market to meet customized needs.

What processing techniques are involved in CNC machining of difficult parts?

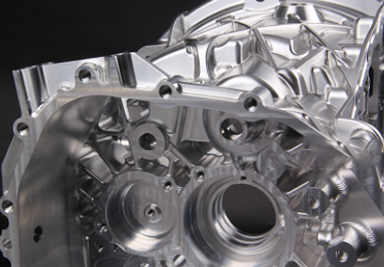

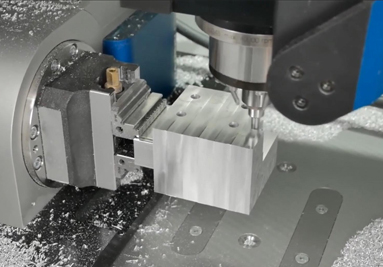

High-difficulty parts are not only reflected in precision, but also in appearance. Some parts are not large in size, but they need to be processed on more than a dozen sides. This is a great test for the clamping method and processing accuracy. If you are not careful, it may lead to scrapping and increase costs. Zhuanxin Precision has many processes and complete equipment. The engineers are experienced and have formulated suitable processing technologies for each high-difficulty product, which greatly reduces the processing risk and cost. Generally, the processes involved in Zhuanxin Precision CNC processing of high-difficulty parts are: CNC milling machine processing (three-axis, four-axis, five-axis), CNC lathe processing, wire cutting, electric spark, grinding, etc.

Unlimited quantity: Whether it is 1 piece of proofing or 1,000 pieces of small batch customization, it can be met.

Unlimited materials: You can choose various metal materials and plastic materials sold on the market to meet customized needs.

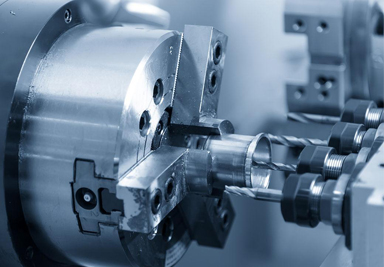

CNC 4-axis machining

EDM

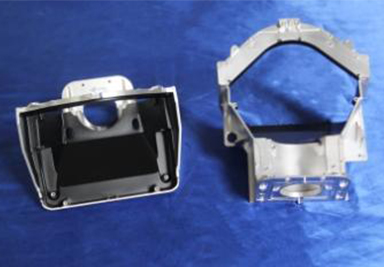

High-difficulty aluminum alloy products

What complex surface treatments are there for CNC machining of difficult parts?

In addition to precision and appearance, the surface treatment of products sometimes increases the difficulty of the product to a certain extent, such as local oxidation, double-sided oxidation, local painting, multi-color spraying, local polishing, secondary electroplating, etc., which are very difficult to handle. Zhuanxin Precision has rich experience in complex surface treatment and has professional masters to help customers handle various complex surfaces.