- Extrusion processing is a critical method which utilizes the principle of plasticity forming of materials to perform extrusion. Through extrusion, to fabricate profiled products with sheet material into tubes, sticks, T shaped, L shaped, U shaped products etc.

- The main needed materials include aluminum, copper, stainless steel, iron, plastic, etc. extrusion is the most common manufacturing method applied in automobile, aerospace, consumer electronics, and mechanical equipments industries du

- Wide range of aluminum profile, meet your mold opening needs,HXC provides a wide range of extrusion products in virtually any sizes or shapes with intricate details.

- Besides, we offer post-treatment and surface treatment service. We have hundreds of material allowing you to select.

- With our advantage of pricing, your products will be more competitive in the market.

Aluminum Profile Custom Center

01 Custom extrusion plant

HXC specializes in the production of high-precision aluminum cold extrusion, tensile forming, development, manufacturing, processing services in one of the enterprises, is a professional auto parts supplier. The main products are filter shell and assembly series, electric fuel pump shell series, tea can series, electrical components shell series.

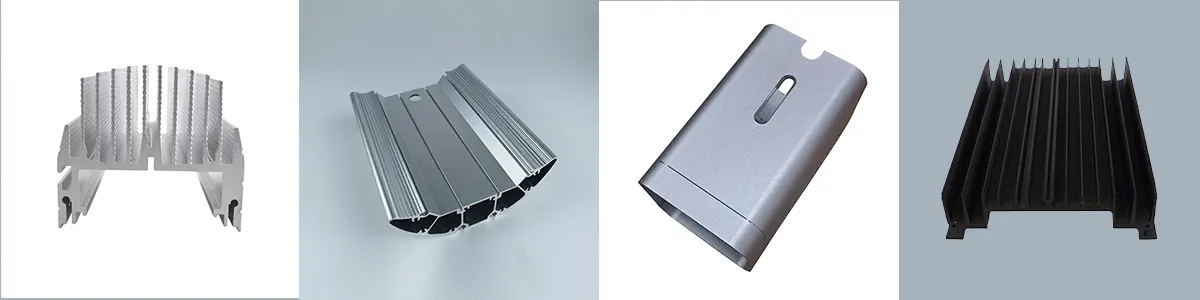

02 Aluminium extrusion products

Specializing in the production and processing of radiators, industrial aluminum, profile, round pipe, square pipe, LED street lamp shell, all kinds of aluminum products, and other varieties up to more than 3000, products are widely used in computers, electronics, electrical appliances, machinery, automobiles, lighting, furniture, sanitary ware, sports equipment, automotive efficiency panels, and other industries and fields.

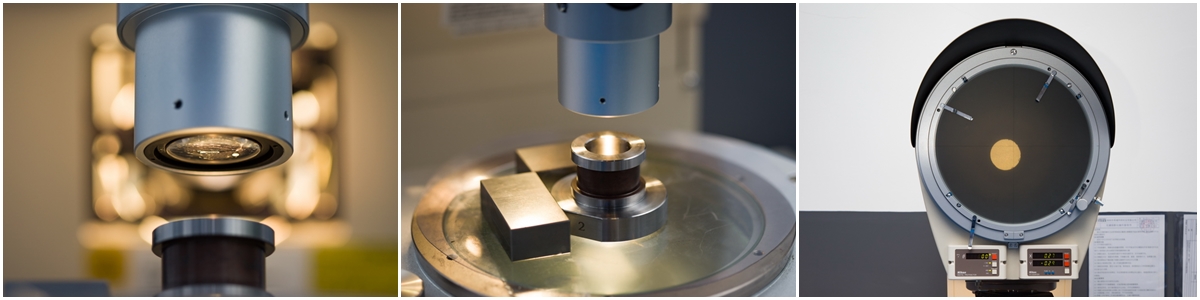

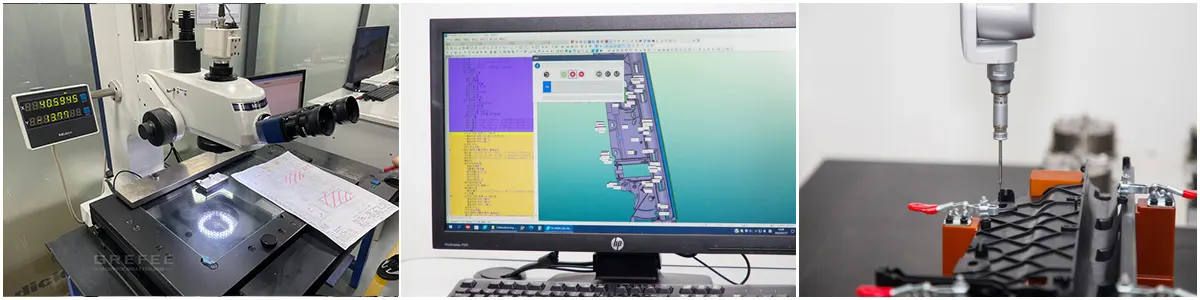

03 Automatic image measuring instrument

Automatic image measuring instrument, it is mainly suitable for all the application fields for the purpose of measurement, in the machinery, electronics, plastic, mold, hardware manufacturing and other industries widely used; It integrates optical, mechanical, electrical and computer image technology. Through high-precision lens imaging, it can carry out microscopic inspection of precision parts, effectively measure the contour and surface shape size, Angle and position of various complex workpieces, and carry out statistical and chart transformation of the measurement.

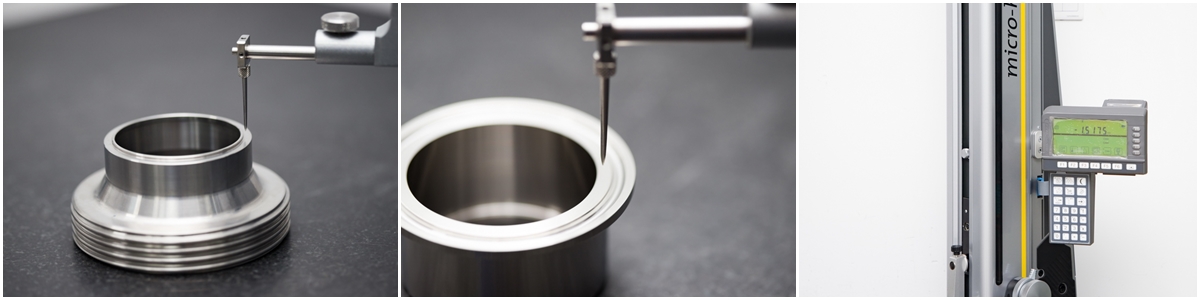

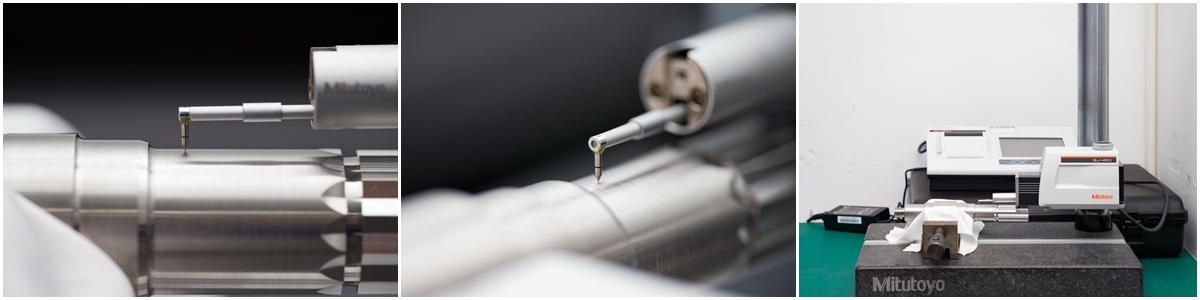

04 Swiss altimeter

It can be used to measure internal dimensions, external dimensions, height, depth or distance dimensions of planar, parallel and cylindrical geometers; Measurements can be made in either one or two dimensions.

05 Handheld X-ray fluorescence spectrometer

The properties required for rapid alloy grade identification and accurate chemical structure analysis of a wide range of materials (solid and powder metals, polymers, light elements (magnesium, aluminum, silicon, phosphorus, sulfur, chlorine), wood, solutions, soils, ores, minerals, etc.);

06 Roughness meter

Mainly used to measure the surface roughness of hardware products, plastic products, also known as finish. Measuring range: 800μm, resolution: 0.0001μm.

07 Profile projector

Profile projector, size, length, shape, profile magnification projection inspection, measurement, comparison, photography, list recording, accuracy 0.0002mm.