Automobile prototype processing case-headlight frame

2025-04-14

Professional and reliable two-color mold and injection molding solutions

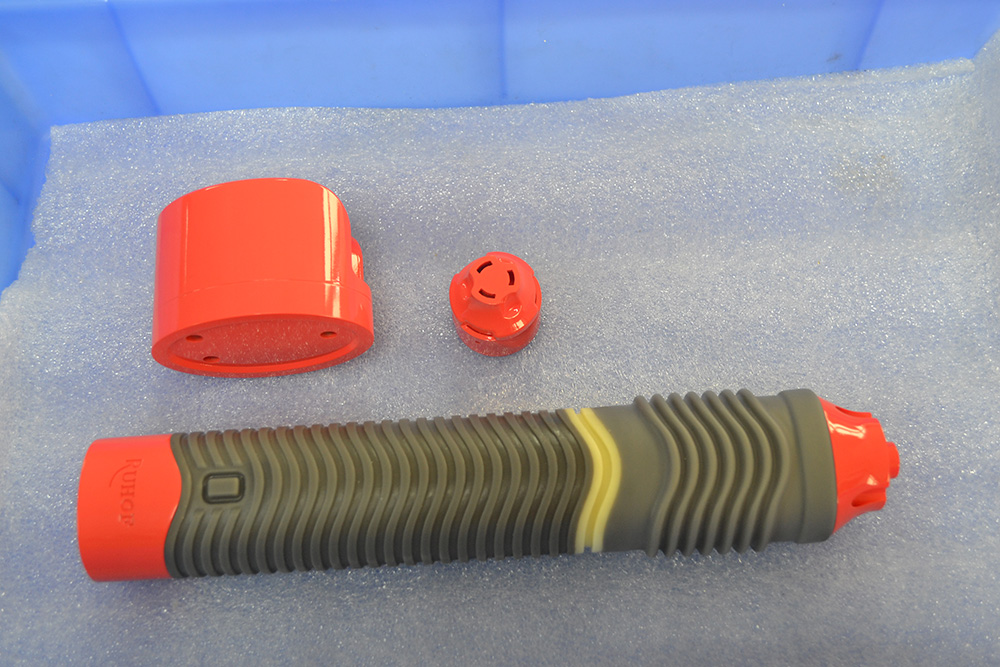

2025-04-16Prototype Case-Medical Cleaner

Processing method: vacuum molding

Material: ABS

Maximum precision: 0.05mm Production cycle: 2~3 days

Product size: 15cm*3cm*3cm

Post-processing: oil spraying

Case Introduction

The prototyping of medical cleaners is a professional process involving multiple steps and sophisticated techniques. Here is the general process of prototyping:

Design stage: Detailed design is required based on the functional and appearance requirements of the medical cleaner. This stage usually requires the use of professional 3D design software to create a digital model of the product.

Prototyping: After the design is completed, a prototype of the product needs to be produced. This prototype is usually used to verify the feasibility of the design and as a reference for subsequent processing.

CNC machining: CNC (computer numerical control) machining is a common prototype manufacturing process that uses programmed instructions to control machine tools to accurately remove materials and produce parts with precise dimensions and complex shapes. CNC machining can process a variety of materials such as ABS, PC, PMMA, aluminum and copper, which have good toughness and strength.

Post-processing: After CNC processing is completed, manual post-processing is usually required, including polishing, painting, printing, etc., to ensure the surface quality and aesthetics of the prototype model.

Silicone duplication: If you need to make multiple sets of prototypes, you can use silicone duplication technology. This method uses the original sample to make a silicone mold, and then pours PU material under vacuum to make a replica that is identical to the original sample. This method is low-cost and suitable for small and medium-sized batch production.

Quality Control: Throughout the entire processing process, strict quality control is required to ensure that each link meets design requirements and industry standards.

Delivery to the customer: After completing all processing steps, the prototype model is delivered to the customer for final testing and verification.

When choosing a suitable supplier, you can consider companies that provide one-stop services, such as HXC, which provides a series of comprehensive solutions from design to prototype models, CNC processing, etc.

In summary, the prototyping of medical cleaners is a complex process that combines modern design and precision manufacturing technology, and requires a professional team and equipment to complete. Through this process, it can be ensured that the design of the medical cleaner is fully verified and optimized before actual production.