3D Printed Rapid Mold

2025-04-16

3D Printing-Smart Cloud Potted Plant Case Study

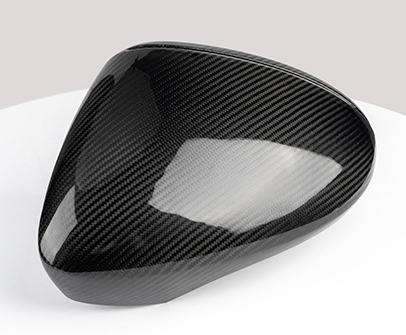

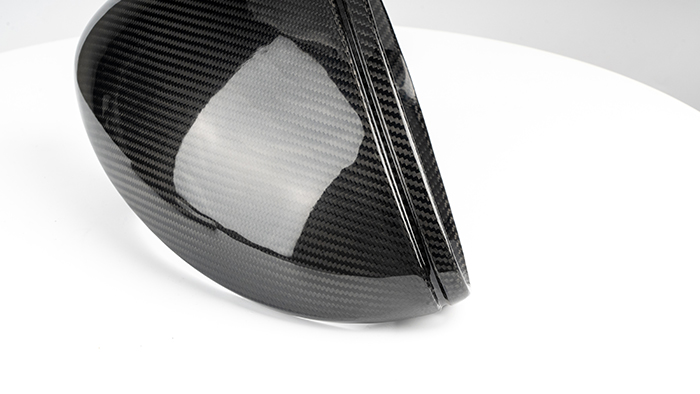

2025-04-19Car prototype processing case-Porsche 911 rearview mirror shell

Processing method: Rapid mold

Material: 3K twill 240g surface

Highest precision: 0.05mm Production cycle: 2~3 days

Product size: 30cm*20cm*18cm

Post-processing: Spray paint

Case Introduction

Car rearview mirror prototype processing refers to the process of making physical samples of car rearview mirrors according to design drawings during the new product development stage. The purpose is to verify the feasibility of the design, check the rationality of the structure, the appearance effect and function test. The following are the steps and processes that may be involved in car rearview mirror prototype processing:

Design and modeling: Use 3D design software (such as CAD) to create a 3D model of the rearview mirror, and perform structural analysis and optimization based on actual needs.

Prototype production: Injection molding: For plastic parts, the injection molding process can be used to quickly manufacture prototypes, by injecting molten plastic into the mold and cooling it. CNC machining: CNC machine tools (such as CNC five-axis machining) are used to precisely carve the shape of the rearview mirror directly from the block material. 3D printing: 3D printing technology (SLA, SLS, FDM, etc.) can also be used to quickly produce prototypes, especially for the design verification of complex structures.

Surface treatment: Sandblasting: used to improve surface roughness and remove processing marks. Grinding and polishing: finely trim the surface of the prototype to make it smooth and flawless. Electroplating/spraying: surface decoration and protective treatment, such as chrome plating, nickel plating, spray painting, etc., to simulate the appearance of the final product. Lens processing: separate processing of the lens part, including cutting, cleaning, hot bending, cooling and shaping, coating (anti-glare, anti-reflection film, etc.), protective paint, edge grinding, frame installation and other steps.

Assembly and testing: After completing the prototype processing of each component, assembly and debugging are carried out to ensure that each component cooperates well and functions normally, such as the electric adjustment mechanism, folding function, heating function, etc. Wind tunnel tests, vibration tests, weather resistance tests, etc. are carried out to verify the performance of the rearview mirror in actual environment.