CNC machining of precision structural parts aluminum alloy

2025-04-08

Display back cover groove texture precision processing solution

2025-04-08Matters Needing Attention in Processing the Shell of Solid State Drive Box

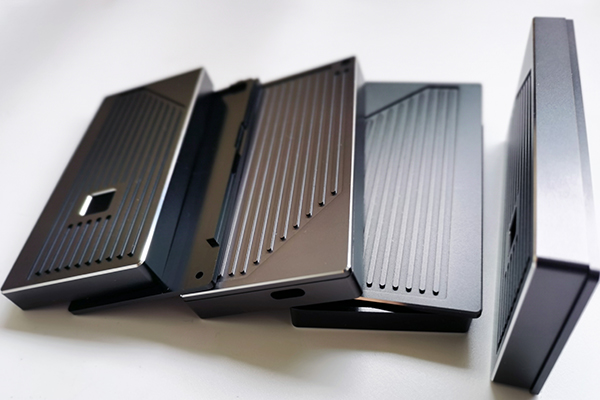

With the rapid development of science and technology, computers and related equipment have been widely used. As an emerging technology in the field of computer storage, solid-state drives are increasingly favored by users due to their advantages such as high-speed reading and writing, stability and energy saving. However, what makes solid-state drives work is not only the high-end technology inside, but also the processing of their shells.

The processing of the SSD enclosure is an important task in the production process of SSDs. Excellent enclosure processing can not only improve the stability, durability and safety of SSDs, but also increase the aesthetics of the product, thereby improving the market competitiveness of the product. However, enclosure processing is not a simple task, and some details need to be paid attention to in order to do better.

The shell material is very important. It must be corrosion-resistant, anti-static, shock-proof, and high-temperature resistant, and the material must meet environmental protection requirements. How to choose the right material? First, you need to understand the performance parameters of the selected material, such as hardness, thermal conductivity, and chemical stability, as well as the influence of various factors in actual use, including weight requirements, appearance, and production costs. Only after a comprehensive analysis of various parameters can the quality of the selected material be ensured.

Secondly, during the processing, attention must be paid to anti-static. The chips and other components of the solid-state drive are particularly sensitive to static electricity, so attention must be paid to anti-static during the processing, otherwise it will cause equipment damage, performance degradation and other problems. Anti-static tools, such as anti-static gloves and anti-static mats, need to be used during the processing to ensure that the product is not disturbed by static electricity.

In addition, the dimensional accuracy and shape accuracy of the parts need to be paid attention to during the processing. If the processing is not accurate or the material is uneven, it will cause the performance of the SSD to deteriorate or not work properly. Therefore, the dimensional and shape accuracy must be strictly controlled during the processing, and high-quality processing equipment and tools must be used to ensure high-precision processing.

Finally, in the process of processing the SSD enclosure, we must pay attention to quality control. Product quality is the key to the production and operation of an enterprise. Only by ensuring product quality can consumers trust and recognize the product and improve market competitiveness. Therefore, it is necessary to establish a perfect quality control system during the processing process, and conduct all-round and full-process quality inspections on the production process to ensure that the SSD enclosure produced is perfect.

In short, SSD enclosure processing is a very important job that requires attention to many details. Material selection, anti-static, quality control and other aspects need to be strengthened. Only through continuous thinking and exploration can we produce higher quality SSDs to meet the needs of the market and users.