Zinc Die Casting Products: FAQ Guide

2024-11-05

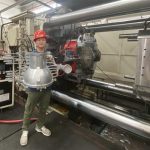

The entire process from design to mold trial for 1650T die – casting

2024-11-05

Magnesium Alloys: FAQ Guide

Magnesium alloy refers to a mixture of magnesium and different metals.

Common metals used to make this alloy include aluminum, copper, zinc, silicon, manganese, zirconium and rare earths.

In general, magnesium alloys are known for various favorable structural properties that make them suitable for different projects and applications.

What are the main types of magnesium alloys?

Technicaly speaking,magnesiumalloys are generally divided into two categories, casting alloys and wrought alloys.

Casting magnesium alloy

These are mainly magnesium types formed by pouring molten liquid metal into a mold and solidifying it into the desired shape.Most cast magnesium alloys consist of significant amounts of manganese, aluminum and zinc as primary alloying elements, but rarely more than 10%.However, other alloying elements such as zirconium are often added, particularly to improve creep resistance.In addition, the mechanical properties of cast magnesium alloys are usually enhanced by heat treatment.

Forged magnesium alloy

These refer to types of magnesium that have undergone various mechanical processes such as extrusion, forging, and rolling operations to achieve the desired shape.Nevertheless, manganese, zinc and aluminum are the main alloying elements of wrought magnesium alloys.Such magnesium alloys are generally divided into heat-treatable alloys and non-heat-treatable alloys.Generally, the compressive strength of wrought magnesium alloys is less than the tensile strength.Furthermore, they exhibit a brushed texture in the deformation direction, which improves the tensile strength.Nonetheless, below are the common magnesium alloys that you will typically find in different applications across various sectors;

Why is using magnesium alloys beneficial for your application?

Magnesium alloys have long been the basis for different applications due to their outstanding properties.Essentially, these alloys are beneficial in several ways in their respective applications.Some beneficial reasons why you should consider magnesium alloys for your project include:

Iight:

Typically, magnesium alloys are 76% and 34% lighter than steel and aluminum, respectively.Essentially, this material is superior to many injection molded thermoplastics in terms of weight.As a result, they can improve efficiency, performance and reliability in different applications.

High versatility

You can easily use magnesium alloys to manufacture parts or components for various applications.This is basic, of course, as it adds convenience.

Environmental friendly:

All magnesium alloy components are 100% recyclable.Additionally, since magnesium is one of the world’s leading abundant elements, it has a constant supply and availability.Essentially, this is beneficial because it means you can get it at an affordable price and its availability is guaranteed.

Thin Wall:

Typically, the nominal wall thickness used to form most magnesium alloy parts is up to 0.5 mm.Ideally, this thin wall provides precise shaping with high strength.Even so, combining the versatility of this process with the mold capabilities, injection molding combines it with incredible material flow.Magnesium alloys therefore open up new complex, space-saving design possibilities in numerous applications.

High strength and vibration reduction:

Typical magnesium alloys have very high tensile strength, about 20 times higher than common engineering thermoplastics.Additionally, it offers high vibration damping properties, making it ideal for most applications where vibration is a concern.

Cost-effective:

Essentially, the fact that magnesium alloys are so versatile and readily available makes them very affordable.Additionally, global availability of this material is increasing, which ensures consistency in large quantities, thereby reducing costs.

How to choose the best magnesium alloy for your application?

Generally, magnesium alloys are very versatile and you can find all sorts of variations of them.But in many cases, it is necessary to research various factors to find the best one for your application needs.Some factors you might consider include the following;

Alloy material composition:

In general, available magnesium alloys are distinguished primarily by the specific alloy material.The essence here is that each alloying material plays a specific role in creating a specific magnesium alloy.

Specific application requirements:

It is worth noting that different applications using magnesium alloys have different requirements depending on the application specifications.It is imperative to study the application requirements so that you can determine the appropriate magnesium alloy to suit it.

Price:

The cost of magnesium alloys generally varies depending on many factors.It is relatively expensive, almost twice as expensive as aluminum alloy.Therefore, it is necessary to find one that fits your budget and suits your specific application requirements.