Deburring and grinding process of synchronizer hub of automobile transmission

2025-03-21

Aluminum alloy high pressure die casting mold case

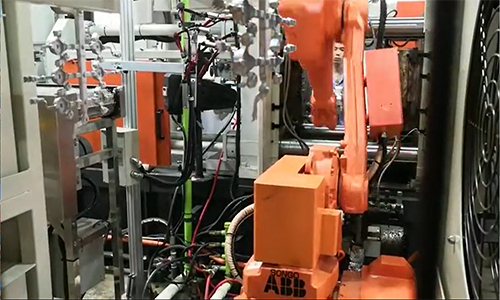

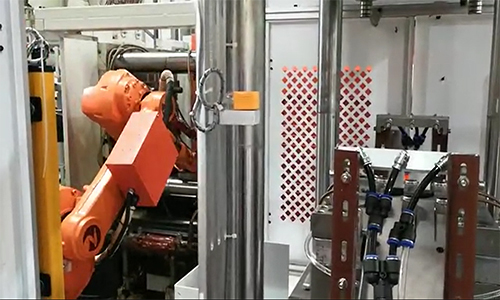

2025-03-22Industrial robot die casting case

Introduction: Die casting is one of the important supporting industries of the automobile industry and has always been closely related to the development of automobiles. The rapid development of the automobile industry in recent years has led to a rapid expansion of the die casting market and given it broad development prospects. Today, with the development of automobile manufacturing technology, die castings are also facing new technical challenges. The structure of the die casting industry is undergoing tremendous changes. Therefore, automated "machine replacement" has begun to be widely used in the die casting industry. "Intelligent process" equipment optimization promotes industry development.

The die-casting industry is one of the important supporting industries of the automobile industry and has always been closely related to the development of automobiles. The rapid development of the automobile industry in recent years has led to a rapid expansion of the die-casting market and given it broad development prospects. Today, with the development of automobile manufacturing technology, die-casting parts are also facing new technical challenges. The structure of the die-casting industry is undergoing tremendous changes. Therefore, automated "machine replacement" has begun to be widely used in the die-casting industry. "Intelligent process" equipment optimization promotes industry development.

HXC robots have been used in the die-casting industry. They significantly improve the quality and durability of castings, improve the working environment of workers, and reduce the risk of repeated manual labor under high intensity. In the increasingly competitive market environment, the series of automated settings introduced by die-casting robots can greatly improve production efficiency and reduce scrap rates. Therefore, HXC robots will become a "hot commodity" in the die-casting industry.

A certain enterprise applied HXC automation solutions to automate and intelligentize the production process, and various processes were equipped with corresponding processing equipment to better realize "machine replacement". The automation equipment independently developed by HXC Company uses conveyor belts and manipulators to realize automatic processing on the parts production line, which greatly reduces the number of workers and greatly improves product quality. "Take the automatic production line of die-casting pots as an example. The company could only produce 1,200 pot bodies per shift, which required 8 operators. After using HXC automation equipment, only 3 people are needed to complete this production capacity."

In addition, the company has reduced labor and energy consumption, and improved production efficiency and product quality by relying on automated assembly lines, die-casting automation and other "machine-for-man" technical transformation projects. In the production workshop, the HXC fully automatic robot welding machine has improved accuracy and efficiency. The original output of two professional welders was 500 pieces per hour. After the technical transformation, two general workers can complete 800 pieces, and the production capacity has increased by 60%.