Display back cover groove texture precision processing solution

2025-04-08

Silicone mold: save time and effort in small batch production

2025-04-11High-precision car model prototype customization

1:5 scale high precision car model prototype sample

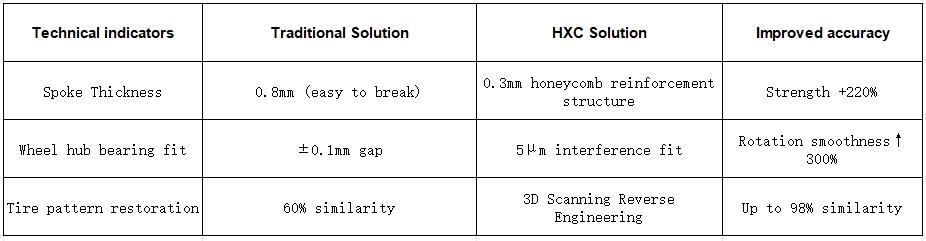

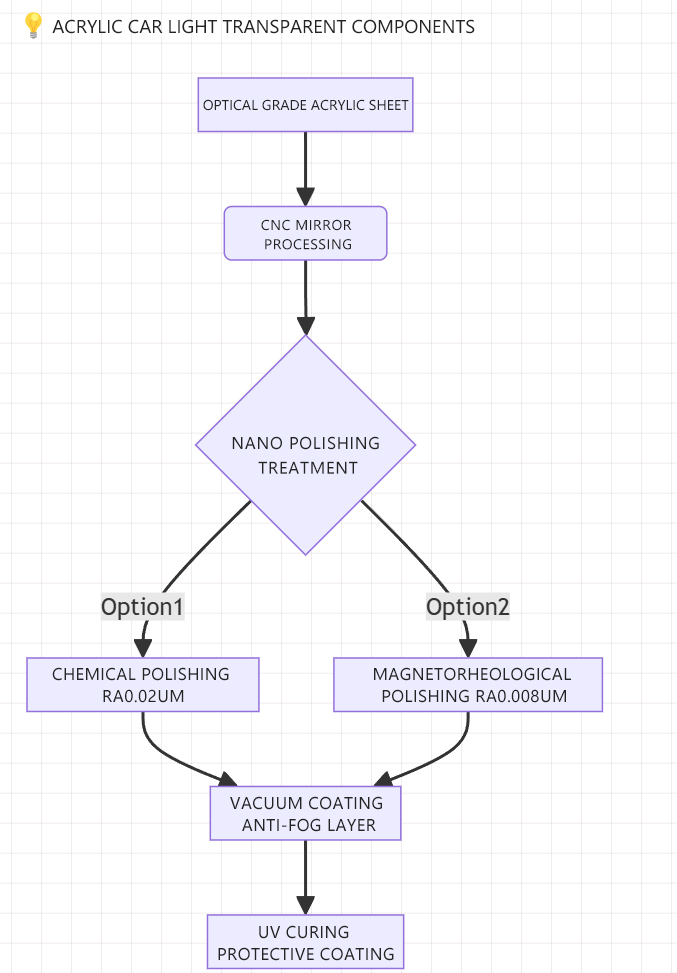

High-precision car model prototype customization | HXC overcomes three major process challenges: 1:5 scaled ABS model miniature wheel 5μm interference fit, 0.15mm thin-wall fence processing, and acrylic headlight transmittance ≥92%

Product core parameters

- Material: ABS+acrylic composite structure

- Scale: 1:5 professional reduction (base vehicle length 4.8 meters → model 960mm)

- Surface treatment: piano black paint (gloss ≥ 95GU)

- Delivery standard: Full component movable structure verification model

Three major process challenges and technological breakthroughs

Miniature wheel assembly processing

Thin-wall molding of air intake grille

0.15mm ultra-thin grid array

Customized 0.1mm diameter milling cutter + HSK25 high-speed toolholder, spindle speed 38,000rpm

Anti-deformation process package

- Low temperature cutting (processing chamber 18±0.5℃)

- Layered cutting strategy (cutting amount per layer 0.02mm)

Online compensation system

Integrated Renishaw OMP60 probe to compensate tool wear in real time

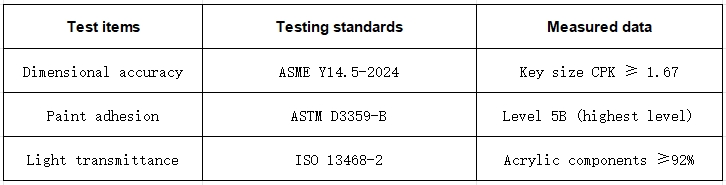

Quality Assurance System

Production environment standards

- Class 1000 dust-free paint shop

- Constant temperature and humidity machining center (23℃±1℃, humidity 45%±5%)

Key test data

Why choose us?

- Automobile prototype laboratory

- Military-grade testing equipment (including three-coordinate measuring machine + white light interferometer)

- 72-hour rapid proofing channel

- Full process confidentiality agreement

Industry Certification

- UL ECVP Environmental Protection Spraying Certification

- NADCAP Special Process Certification