CAESES and FLOW-3D Coupling Optimization Case

2025-03-21Deburring and grinding process of synchronizer hub of automobile transmission

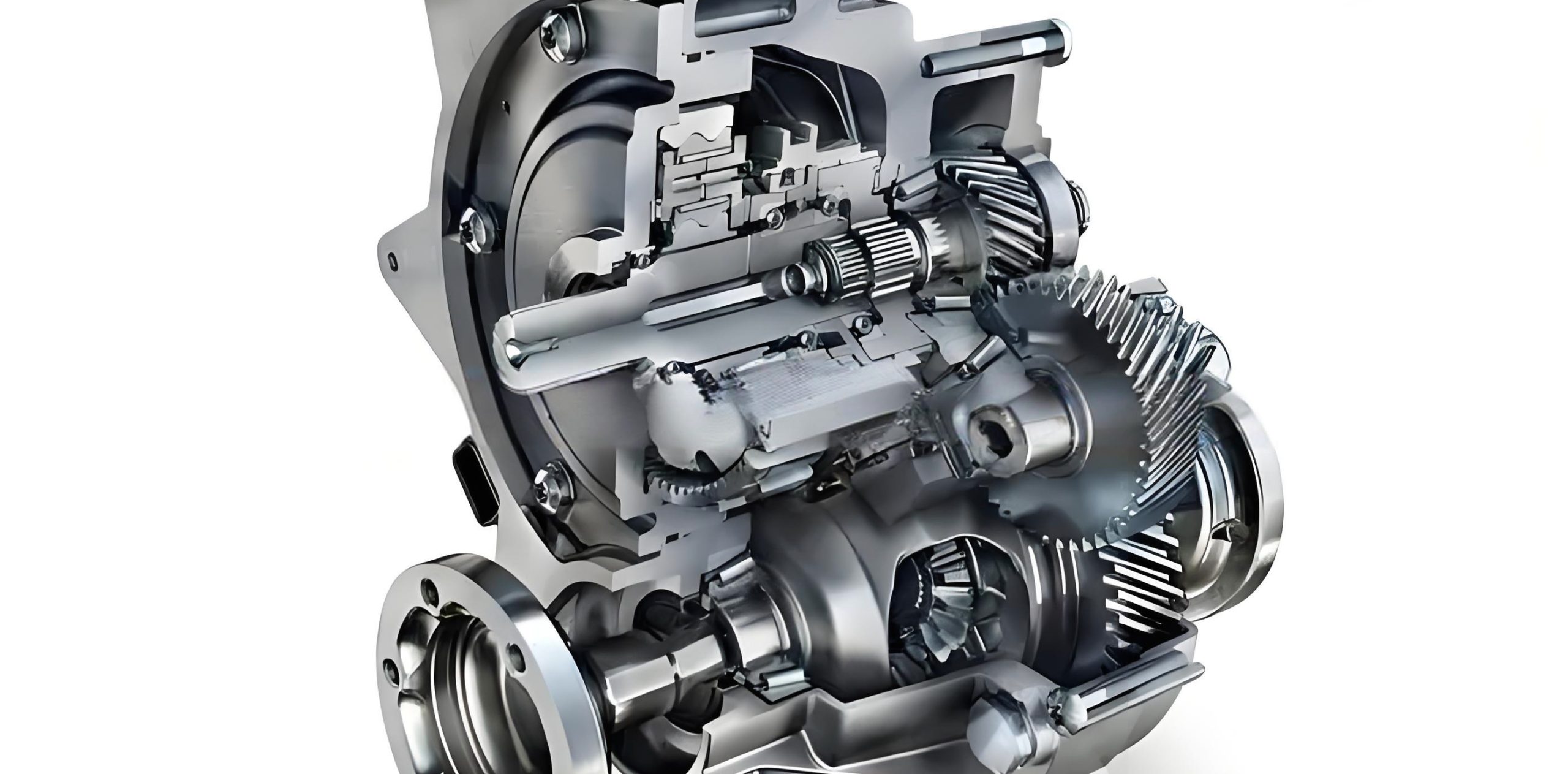

As a key component of automobiles, automobile transmissions have particularly strict requirements on the material, form and position tolerance, surface quality and other factors of the mechanical parts assembled therein. The synchronizer hub is an indispensable and important component of the transmission, which is mainly used to reduce the impact between gears when the car shifts gears and realize smooth speed change of the car.

Synchronizer hubs are generally produced by powder metallurgy. During the processing and forming process, due to reasons such as molds, processes or raw materials, visible burrs and burrs often appear on the edges between the teeth or the middle keyway of the product. The existence of this burr phenomenon will have an adverse effect on the surface quality of the product, and have a great impact on the mechanical properties, safety, and user experience of the transmission assembly. Today we will share a case of how to remove burrs and flash from automobile synchronizer hub products and achieve high-efficiency grinding and polishing in large quantities. This grinding process method is also applicable to the deburring and grinding and polishing needs of other automobile parts such as powder metallurgy or castings such as gears, gear rings, and gear sleeves.

1. The synchronizer gear hub before deburring, grinding and polishing

2. Polishing and deburring requirements:

Batch and efficient removal of burrs, flashes, and rough edges to improve surface brightness.

3. Synchronizer gear hub deburring, grinding and polishing process details:

4. Comparison of the effects of deburring, grinding and polishing of synchronizer gear hub

5. Additional Notes

The main production process of synchronizer gear hub is powder metallurgy. After sintering, it needs to be trimmed to improve the dimensional accuracy of the sintered product and ensure that the product accuracy meets the requirements of synchronizer gear hub. The burrs are mainly concentrated on the edges of the tooth edges and keyways, and the daily processing quantity is large. Therefore, a vibration grinding and polishing machine is used to remove the burrs with a heavy cutting force coarse grinding and polishing abrasive. The sharp angle of the abrasive can penetrate into the grooves between the tooth edges to achieve the effect of removing burrs and chamfering.

The fine grinding and polishing brightness is also achieved by using a vibration grinding and finishing machine, using high-density precision polishing abrasives with slight cutting force, which can improve the surface brightness while cutting a small amount and reducing the roughness.

In order to improve the anti-rust and anti-corrosion performance of the product after water, it is immersed in a rust inhibitor for anti-rust treatment after polishing, and finally a vibration dryer is used to dry the surface moisture and dry it.

6. Final summary

In this case, we demonstrated the process of surface chamfering, deburring and polishing of a powder metallurgy synchronizer gear hub component.

This process is also applicable to the surface polishing of powder metallurgy sprockets, bushings, structural parts, 3D printing products and metal powder injection molding products.