Industrial notebook aluminum alloy middle frame CNC processing case

2025-04-07

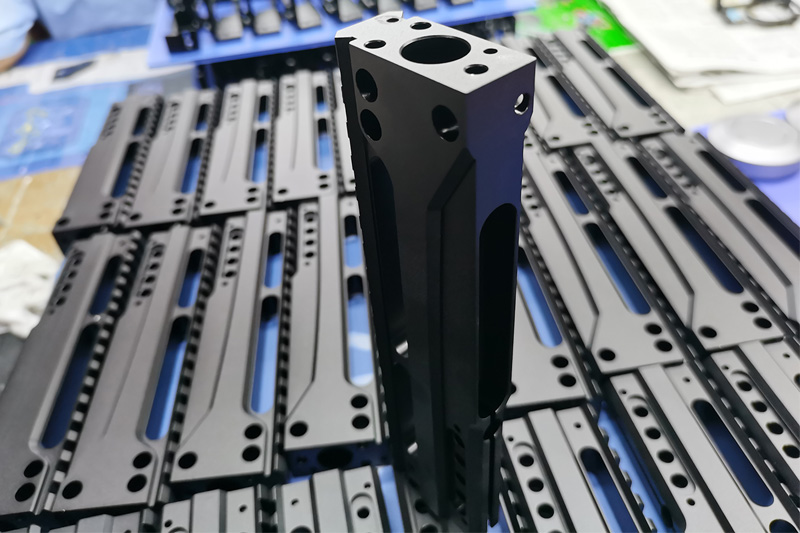

Solid state drive box shell processing

2025-04-08CNC machining of precision structural parts aluminum alloy

Precision CNC machining of aluminum alloy structural parts

1. Technical points of CNC machining of precision structural aluminum alloy parts:

Material selection and preparation

Before CNC machining of precision structural aluminum alloy parts, you first need to select suitable aluminum alloy materials. Common aluminum alloy materials include aluminum-manganese alloy, aluminum-magnesium alloy, etc. Select the appropriate material according to the specific requirements of the product. In addition, the material needs to be reasonably cut and heat treated to ensure the quality and performance of the processed product.

Tool selection and tool path optimization

The choice of tool has a great influence on the results of CNC machining. Generally, choosing the right tool material and tool type, such as carbide tools, high-speed steel tools, etc., can improve accuracy and machining efficiency. At the same time, by optimizing the tool path and reducing the number of cuts and cutting time, the machining efficiency can be further improved and the cost can be reduced.

Reasonable setting of machining parameters

The machining parameters have an important influence on the quality and efficiency of CNC machining. Reasonable setting of parameters such as cutting speed, feed speed, cutting depth, etc. can ensure the surface quality and dimensional accuracy of aluminum alloy parts and avoid machining defects caused by too high or too low parameters.

Quality inspection and adjustment

During the CNC processing process, the processed aluminum alloy parts need to be inspected and adjusted. By using measuring instruments and equipment, such as micrometers and measuring tools, the size and surface finish of the product are inspected, and adjustments and repairs are made in time to ensure the quality and accuracy of the product.

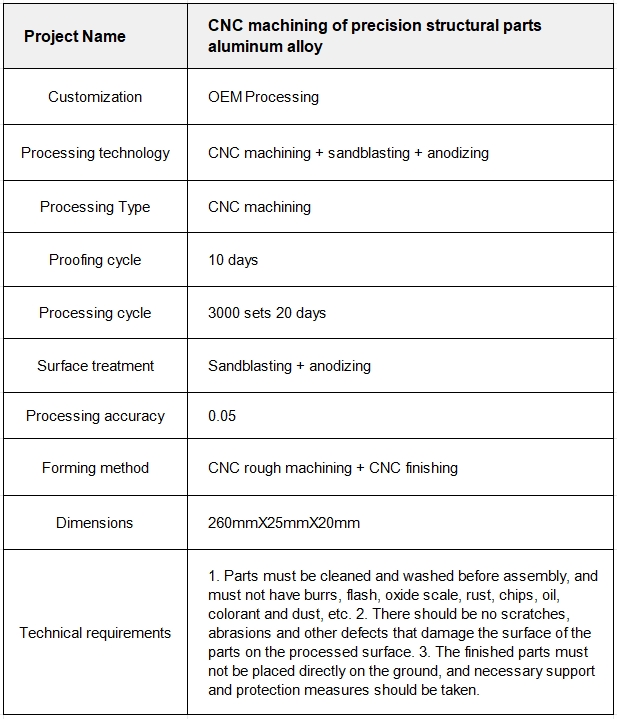

Processing parameters

2. Advantages of CNC machining of precision structural aluminum alloy parts

High precision and high efficiency

With its advanced automation technology and precise processing process, CNC machining can achieve high-precision machining and ensure the dimensional accuracy and surface quality of the product. At the same time, CNC machining is also characterized by high efficiency, which can greatly improve production efficiency and capacity.

Flexibility and customizability

CNC machining technology can be programmed and processed according to different product requirements, with strong flexibility. Whether it is mass production or small batch customization, CNC machining can meet different needs and provide more business opportunities for enterprises.

Cost control and production efficiency

Compared with traditional manual machining or other machining technologies, CNC machining has advantages in cost control and production efficiency. Through automated machining processes and efficient production, CNC machining can reduce production costs, save human resources, and provide more products in a shorter time.

As an advanced processing technology, CNC processing of precision structural aluminum alloy parts has been widely used in many industries due to its high precision, high efficiency and flexibility. Through reasonable material selection and preparation, tool selection and tool path optimization, reasonable setting of processing parameters, quality inspection and adjustment and other technical points, high-quality processing of precision structural aluminum alloy parts can be achieved. I believe that through the application of CNC processing technology, your products will gain greater market competitiveness and commercial value.