Silicone mold: save time and effort in small batch production

2025-04-11

Automobile prototype processing case-headlight frame

2025-04-14Automobile prototype processing case-housing parts

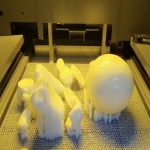

Processing method: Vacuum molding

Material used: PX5690 (similar to ABS)

Maximum precision: 0.05mm Production cycle: 1~2 days

Product size: 48 cm * 19.5cm * 9 cm

Post-processing: Matte spray

Case Introduction

Prototyping of automotive shell parts is a key step in the automotive manufacturing and design process. It involves creating physical models or prototypes that are used to verify the appearance, size, fit and functionality of new designs. Prototyping is usually performed before mass production to ensure that the design meets all technical and quality requirements. The following is the general process of prototyping of automotive shell parts:

Design and Modeling: Use computer-aided design (CAD) software to create detailed designs of automotive components. These drawings will include all the necessary sizes, shapes, and details of fittings.

Material selection: Choose the appropriate material according to the purpose and characteristics of the prototype, such as ABS plastic, polyurethane, composite material or metal.

Manufacturing method: Select appropriate rapid prototyping technology based on design complexity and quantity, such as stereolithography (SLA), selective laser melting (SLM), CNC milling or turning, etc.

Post-processing: After rapid prototyping, sanding, filling, painting, polishing or other surface treatments may be required to improve the appearance and texture of the prototype.

Assembly and testing: The prototype is installed on the car for actual assembly testing to check its fit, structural strength and functional performance.

Evaluation and Optimization: Make necessary modifications and optimizations to the prototype based on the test results until the design and technical standards are met.

Final Confirmation: When the prototype passes all tests and meets all requirements, it can proceed to the next step, such as the production of mass production molds and production preparation.

Prototyping of automotive housing parts not only helps identify potential design issues, but also provides physical samples for engineers and designers to conduct actual evaluation and improvement. This process is critical to ensuring final product quality, shortening development cycles, and controlling costs.