Customized case of virus collection tube precision mold

2025-03-05

Bubble tracking in gravity casting gating system

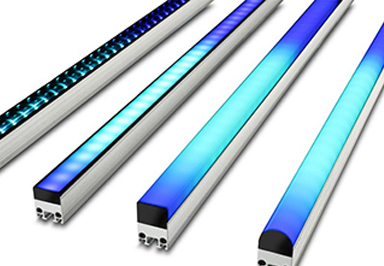

2025-03-08Art Lighting Solutions

HXC has been providing one-stop service of industrial manufacturing solutions to customers around the world, from rapid prototyping and manufacturing of products to industrial mass production, using a variety of processes and involving multiple fields to fully meet customer requirements and exceed customer expectations.

In the field of artistic lighting, HXC has a wealth of industry experience. Since 2010, it has cooperated with the world-renowned company Harman Martin to develop and produce a series of artistic lighting. In the past 13 years, a series of new products have been launched, and recently, updated models have also been launched. After years of exploration and improvement, in terms of production technology, most of the components are produced mainly by injection molding, aluminum alloy die casting, and precision CNC processing. Linear lights are mainly produced by plastic extrusion and aluminum extrusion.

Each injection molding component requires an injection mold, and die castings require die casting molds. The production and use of molds can greatly reduce the cost of each piece in the later batch production.

Typical products

Lamp type: single pixel stage light

Shell material: cast aluminum

Protection level: IP65, lead-free certified

Main production process: injection molding, die casting, CNC precision machining, matte finish in the later stage

Lamp type: single pixel stage light

Shell material: cast aluminum

Protection level: IP65, lead-free certified

Main production process: injection molding, die casting, CNC precision machining, matte finish in the later stage

Lamp type: flash lamp

Casing material: aluminum alloy, high impact thermoplastic, flame retardant in accordance with UL 94 5VA standard

Protection level: IP20

Main production process: injection molding, die casting, CNC precision machining

Lamp type: cold light stage beam moving head light

Shell material: highly flame-retardant thermoplastic

Protection level: IP20

Main production process: injection molding, die casting, CNC precision machining

Lamp type: warm light stage beam moving head light

Shell material: highly flame-retardant thermoplastic

Protection level: IP20

Main production process: injection molding, die casting, CNC precision machining

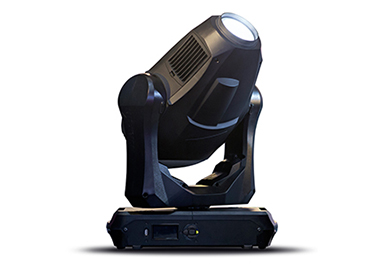

Lamp type: stage beam moving head light

Shell material: highly flame-retardant thermoplastic

Protection level: IP20

Main production process: injection molding, die casting, CNC precision machining

Lamp type: stage dye lamp

Shell material: highly flame-retardant thermoplastic

Protection level: IP20

Main production process: injection molding, die casting, CNC precision machining

Lamp type: stage wash lamp

Housing material: high impact thermoplastic, flame retardant in accordance with UL 94 5VA standard

Protection level: IP20

Main production process: injection molding, die casting, CNC precision machining

Lamp type: bright white light stage beam moving head LED lamp

Shell material: highly flame-retardant thermoplastic

Protection level: IP20

Main production process: injection molding, die casting, CNC precision machining

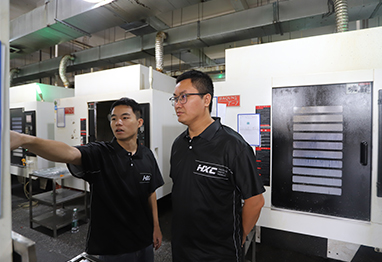

Enterprise Strength

HXC has 83 CNC machining centers, including 4 5-axis German HERMLE CNC machining centers and 7 88T-500T die-casting machines. It has precision mold processing equipment such as AGIE spark machines, Sodick spark machines, Okuma, FANUC, Sumitomo and Sodick molding injection machines, as well as CMM fully automatic measurement laboratories, German GOM blue light 3D detectors, etc.

The company has a team of precision plastic molds and injection molding processing experts with rich theoretical and practical experience. The core members have more than 20 years of experience in the mold industry and have many core technologies and national patents in complex mold structure, mold flow analysis, conformal cooling technology, and processing thermal deformation management.