Deburring technology for magnesium alloy notebook middle frame

2025-03-26

What exactly is the “CNC process” used in smart lock processing?

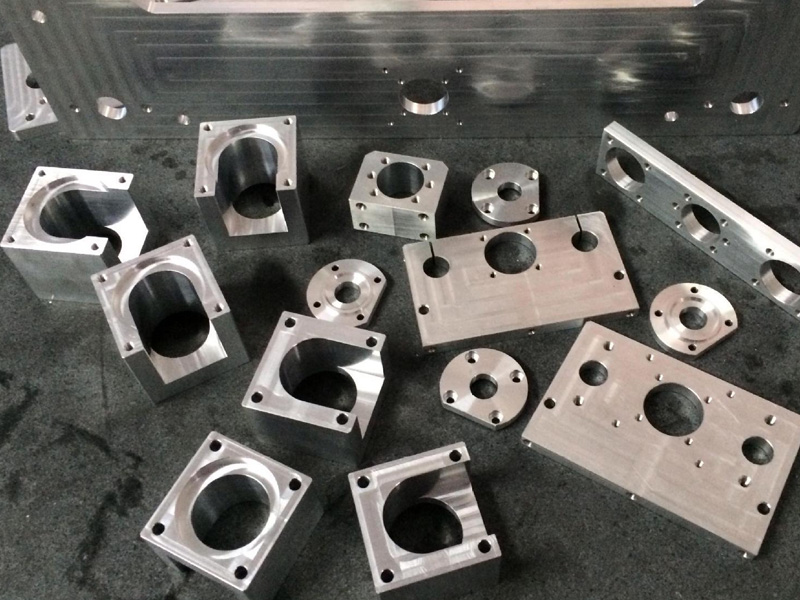

2025-03-27Aluminum Alloy CNC Machining: Process, Advantages and Application Cases

Aluminum alloy CNC machining is an efficient CNC machine tool machining technology widely used in precision machining of aluminum alloy materials. CNC, Computer numerical control machine tools can control various parameters during the machining process through programming, achieving high-precision and high-efficiency machining.

1、 Overview of CNC machining technology

CNC machining technology precisely controls the position coordinates, tool feed rate, spindle speed, etc. of aluminum alloy workpieces through CNC machining language. This technology can complete various machining operations such as drilling, tapping, milling, cutting, etc. in one go, greatly improving production efficiency.

2、 Significant advantages of CNC machining

Compared with traditional processing techniques, aluminum alloy shells made by CNC machining have the following advantages:

1. High strength: Aluminum alloys and their alloys have high strength, which can be further improved by cold working or heat treatment.

2. Processing stability: The CNC machining process is stable, avoiding human processing deviations and ensuring consistent quality of each aluminum alloy shell.

3. Production of complex components: CNC machining can produce aluminum alloy parts with complex shapes and high precision requirements, meeting diverse production needs.

3、Application examples of CNC machining technology