Research on 5-axis CNC machining of vortex stainless steel impeller

2025-03-28

CNC machining of humanoid robot structural parts

2025-03-315-Axis CNC Machining of Medical Titanium Bone Plates (TC4) Case Study

1. Background

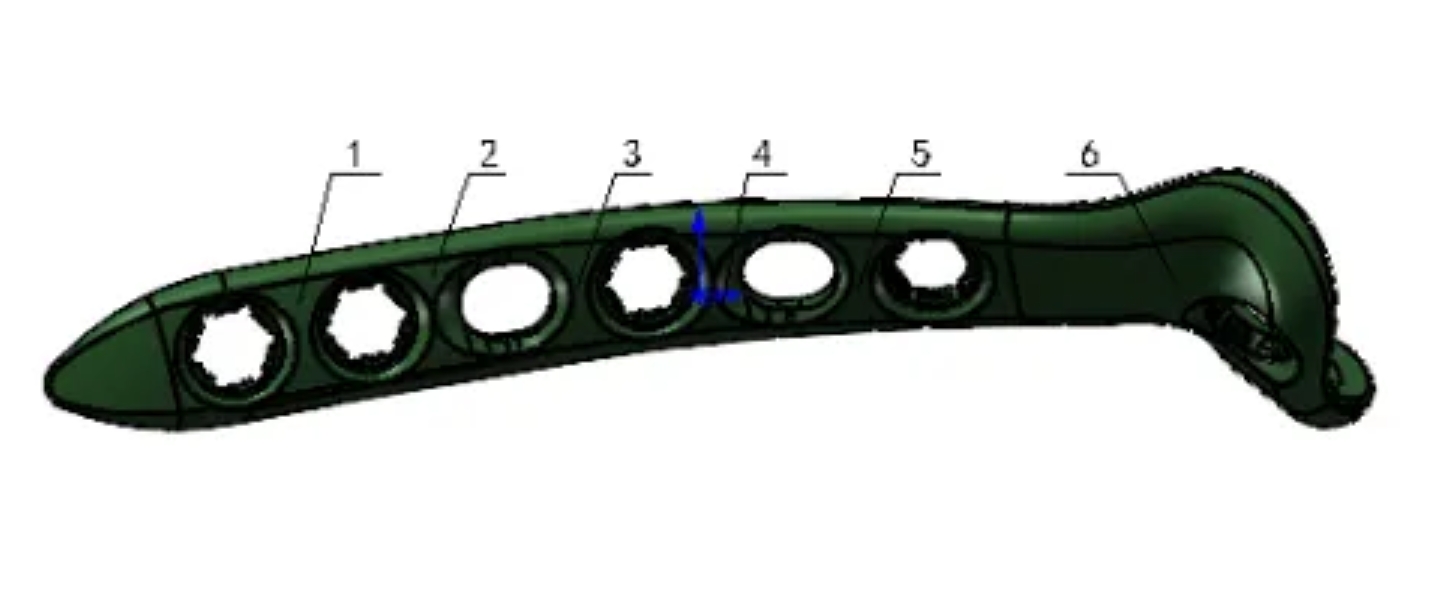

In the medical field,

Bone Plate

As an important device for repairing fractures, bone plates have strict material and processing requirements. This case study shows Yixin Precision's successful experience in machining TC4 titanium alloy bone plates using 5-axis CNC technology.

TC4

TC4 (Ti-6Al-4V) has become the material of choice for medical implants due to its excellent biocompatibility, high strength, light weight and corrosion resistance. However, TC4 is also a recognized difficult-to-process material, so how to accurately process bone plates that meet medical standards has become a challenge.

2. Materials and technical challenges

The main machining challenges of TC4 titanium alloy include:

Poor thermal conductivity:

The heat generated during machining cannot be dissipated quickly, which can easily cause tool overheating and shorten tool life.

High strength and toughness:

This increases cutting forces and tool wear during machining.

Elastic deformation:

TC4 has a low elastic modulus and is prone to slight deformation during machining, especially when manufacturing high-precision medical devices.

Therefore, machining such parts requires high-precision equipment and strict process control. 5-axis CNC machines can provide advantages in these aspects, including reducing errors caused by multiple clamping and being able to complete the machining of complex surfaces in one go.

3. Advantages of 5-axis CNC machining

HXC Precision

HXC uses advanced 5-axis CNC technology, and its main advantages include:

High precision:

5-axis CNC can complete the processing of complex geometric shapes without multiple repositioning of parts, significantly improving processing accuracy.

Complex surface processing:

The design of bone plates usually needs to conform to the natural curvature of human bones. 5-axis linkage can easily process complex surfaces from multiple angles.

Reduce the number of clamping times:

All-round processing can be completed in one clamping, which reduces the time of repeated positioning, improves processing efficiency and reduces potential errors.

4. Processing flow

To ensure the accuracy and surface quality of the bone plate, HXC Precision follows the following processing steps:

Design and programming:

Based on the CAD drawings provided by the customer, Yixin Precision's engineering team programs the processing path of the parts in detail, especially the curved surface part, to ensure the consistency of the processing path with the design.

Roughing and finishing:

Use 5-axis CNC for roughing to remove most of the material, and then perform finishing to ensure the required dimensional accuracy and surface finish.

Surface treatment:

In order to meet the strict requirements of medical devices, the bone plate is surface treated after processing, such as deburring and polishing, to ensure that its surface is smooth and defect-free.

5. Quality Control

Quality inspection is crucial in the production of medical devices. In order to ensure the performance of the bone plate, HXC has precisely implemented the following quality control measures:

Dimension inspection:

Use a high-precision coordinate measuring machine (CMM) to inspect the key dimensions of the bone plate to ensure that it meets the design tolerance requirements.

Surface quality inspection:

Use a microscope to check whether the surface has burrs, cracks or other defects that may affect the safety of implantation.

Mechanical property testing:

The finished product is tested for tensile strength, fatigue strength, etc. to ensure its durability and reliability in actual use.

6. Compliance requirements in the medical industry

As a medical device, the production of bone plates must meet strict industry standards. HXC Precision also has the ISO13485 medical device quality management system certification. HXC Precision strictly follows the ISO 13485 medical device quality management system to ensure that every link from material procurement, processing to testing meets the standards. In addition, TC4 titanium alloy bone plates must pass a series of biocompatibility tests to ensure their safety and stability in the human body.

7. Conclusion

Through this case study, we can see that HXC Precision successfully used 5-axis CNC technology to solve the difficulties in TC4 titanium alloy processing, ensuring the high standards of bone plates in terms of biocompatibility, mechanical strength and surface quality. This case not only demonstrates HXC Precision's technical strength in processing difficult materials, but also shows that it has excellent experience and capabilities in the field of medical device manufacturing, providing customers with products that meet the strict requirements of the medical industry. It also highlights HXC Precision's innovative capabilities in the medical field and its advantages in providing customized high-precision component solutions.