CNC machining of humanoid robot structural parts

2025-03-31

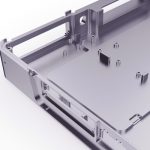

Industrial notebook aluminum alloy middle frame CNC processing case

2025-04-075-axis CNC machining for automotive parts manufacturers

In the dynamic world of automotive manufacturing, precision and innovation are the driving forces for superior performance and reliability. As demand for lightweight, high-strength and complex-design automotive parts continues to grow, manufacturers are increasingly turning to 5-axis CNC machining. This advanced technology offers unparalleled precision, flexibility and efficiency, making it the gold standard for automotive component manufacturers around the world.

HXC is at the forefront of this revolution, delivering premium 5-axis CNC machined auto parts that meet the exacting standards of automotive OEMs and aftermarket suppliers. In this comprehensive guide, we’ll explore how 5-axis CNC machining is changing auto part manufacturing and why HXC is the top choice for precision automotive components.

1. Advantages of five-axis CNC machining of automotive parts

Complex geometries can be achieved with a single setup

One of the main advantages of 5-axis CNC machining is its ability to machine complex geometries in a single setup. This capability eliminates the need for multiple fixtures and manual repositioning, significantly reducing cycle times and improving accuracy.

- Complex turbocharger impellers: Made from heat-resistant materials such as Inconel 718, these components require high-precision milling and the best possible surface finish.

- LIGHTWEIGHT SUSPENSION ARM: Machined from 7075-T6 aluminum for maximum strength-to-weight ratio, perfect for high-performance vehicles.

- Cylinder Head and Engine Block: Precision milled to accommodate coolant passages, minimizing thermal stress and maximizing efficiency.

2. Precision and tolerance control

In automotive machining, achieving tight tolerances is critical. HXC’s 5-axis CNC machines maintain dimensional accuracy within ±0.005mm, meeting the most stringent performance and safety requirements.

- Brake Caliper: Precision milled for consistent braking force and reliable performance.

- Fuel Injector Housing: Machined with high precision to maintain optimal fuel delivery and combustion efficiency.

3. Material versatility

Automotive parts are often made from a variety of materials to meet performance and durability standards. HXC's CNC machining services cover a variety of materials, including:

- Aluminum Alloys (6061, 7075): Lightweight and corrosion-resistant, ideal for engine parts and body components.

- Stainless steel (304, 316): high strength, corrosion resistance, suitable for exhaust manifolds and brackets.

- Titanium Alloy (Ti-6Al-4V): Excellent strength-to-weight ratio for critical load-bearing components.

- Inconel alloys and super alloys: Suitable for high temperature applications such as turbocharger components.

4. Key Factors for Choosing 5-Axis CNC Machining for Auto Parts Manufacturers

Advanced Equipment and Technology

State-of-the-art CNC machines such as the DMG Mori NHX 6300 and Haas UMC-750 are essential to achieve the precision and efficiency required for automotive applications.

Quality Assurance and Certification

Work with manufacturers that adhere to IATF 16949 and ISO 9001 standards to guarantee consistent quality and process reliability.

End-to-end Production Capabilities

A reliable manufacturer should offer a full range of services, from prototyping and low-volume production to high-volume manufacturing, as well as post-processing services such as anodizing, coating, and laser engraving.

5. Practical applications and case studies

High performance brake calipers

Turbocharger housing

By using 5-axis CNC machining, HXC produces turbocharger housings from Inconel 718, achieving high precision on thin-wall sections while maintaining material integrity under extreme temperatures.

6. Future trends in CNC machining of automotive parts

Advanced Equipment and Technology

State-of-the-art CNC machines such as the DMG Mori NHX 6300 and Haas UMC-750 are essential to achieve the precision and efficiency required for automotive applications.

Quality Assurance and Certification

Work with manufacturers that adhere to IATF 16949 and ISO 9001 standards to guarantee consistent quality and process reliability.

End-to-end Production Capabilities

A reliable manufacturer should offer a full range of services, from prototyping and low-volume production to high-volume manufacturing, as well as post-processing services such as anodizing, coating, and laser engraving.

in conclusion

Choosing the right 5-axis CNC machining automotive parts manufacturer is critical to achieving consistent quality, precision, and cost efficiency. With cutting-edge technology, unmatched expertise, and comprehensive services, HXC is your partner of choice for advanced automotive solutions. Contact us today to discuss your project and get a free quote!