Stage light die-cast parts customized

2024-10-19

CNC machining details

2024-10-21

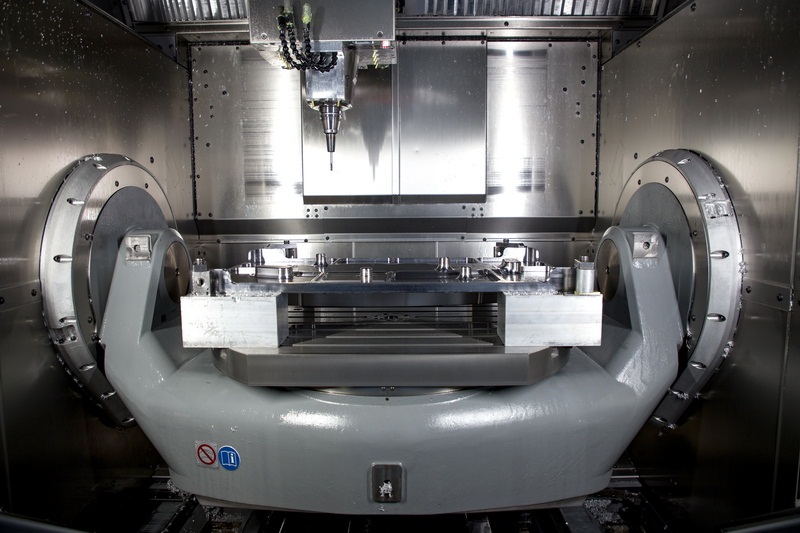

A good helper for precision molds - 5-axis CNC machining center

HXC owns world leading 5-axis CNC machining centers: German Hammer C22, C42, C62, with mold processing accuracy of 0.002mm.

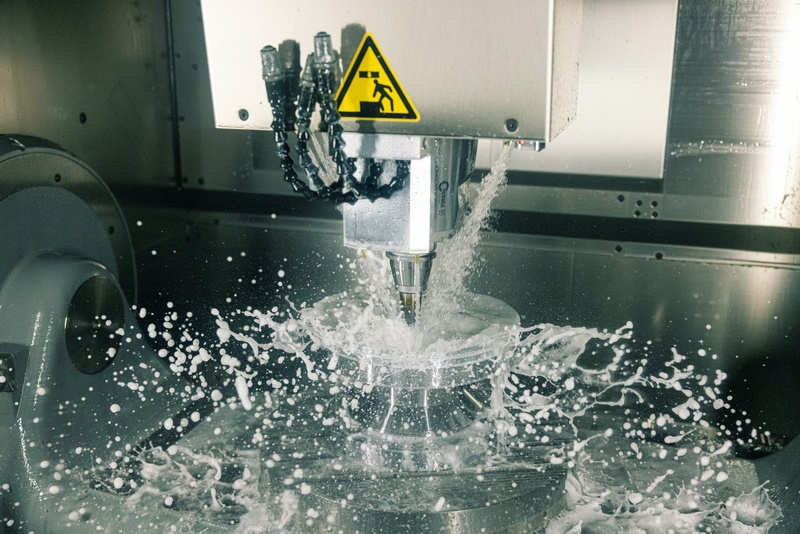

A five-axis CNC machining equipment is a highly advanced manufacturing tool that utilizes computer numerical control (CNC) technology to perform complex and precise machining operations. This equipment is equipped with five axes of motion, which allows for greater flexibility and capability in shaping and cutting various materials.

The five axes typically consist of three linear axes (X, Y, and Z) that control the movement of the cutting tool in three-dimensional space, and two additional rotational axes (often referred to as A and C axes) that enable the workpiece or the cutting tool to rotate around specific axes. This multi-axis capability allows for the creation of intricate geometries and features that would be difficult or impossible to achieve with traditional three-axis CNC machines.

The five-axis CNC machining equipment is capable of performing a wide range of machining operations, including milling, drilling, tapping, and contouring, with high accuracy and repeatability. It is widely used in the aerospace, automotive, medical, and precision engineering industries, where the production of complex and high-precision components is critical.

The equipment is typically controlled by sophisticated software that allows operators to program the machining operations, simulate the cutting process, and monitor the machine's performance in real-time. This ensures optimal machining efficiency, reduces waste, and minimizes the risk of errors or defects in the finished products.

Overall, five-axis CNC machining equipment represents a significant advancement in manufacturing technology, enabling the production of high-quality, complex components with unparalleled precision and efficiency.

German Hammer C22, C42, C62, with mold processing accuracy of 0.002mm. Suitable for precision CNC, precision mold processing, complex shape processing, etc., with improved efficiency and precision, it is a good helper for precision mold manufacturing!