3D Printing – Car Grille Case Study

2025-04-23

Application of 3D Printing in Dentistry

2025-04-24Rapid Prototyping 3D Printing-Headphone Case Study

Nowadays, headphones have become an indispensable device for people to carry with them when they go out. Some people like the bold personality of headphones, while others prefer the low-key and restrained in-ear headphones. With the advancement of technology and the changes of the times, the types and styles of headphones are constantly being innovated, highlighting the sense of technology and focusing on personalization. Compared with traditional crafts, the advantage of 3D printing technology is that what you think is what you get. 3D printing technology has become the trend of the times.

Project Analysis

After receiving the 3D drawings from the customer, the pre-analysts conducted process analysis, actions, disassembly and developed production processes according to the customer's specified requirements. This headset has a complex shape, with many edges and small parts. If it is processed by traditional CNC, the materials, costs, time and manpower consumed are very huge. After evaluation, our professional analysts decided to use SLA laser curing rapid prototyping technology, which can be quickly formed through 3D printing and is easy to process later.

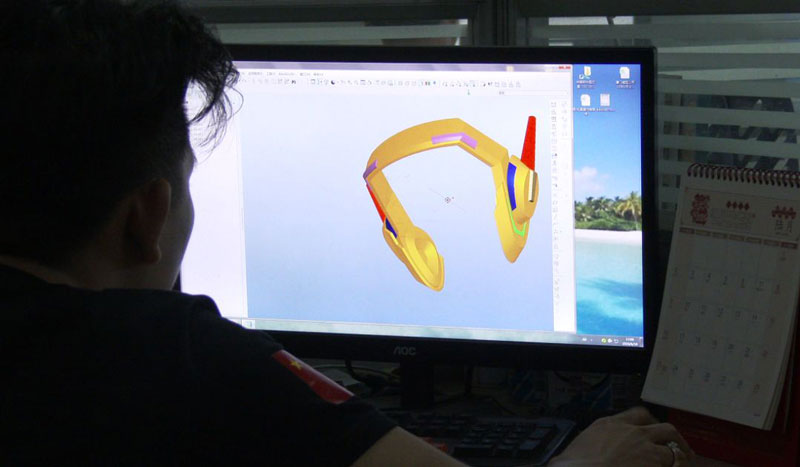

Headphones 3D drawing

Preliminary analysis and selection of production process

Production Process

1. After the preliminary analysis is completed, disassemble the parts and check the overall matching degree of the parts

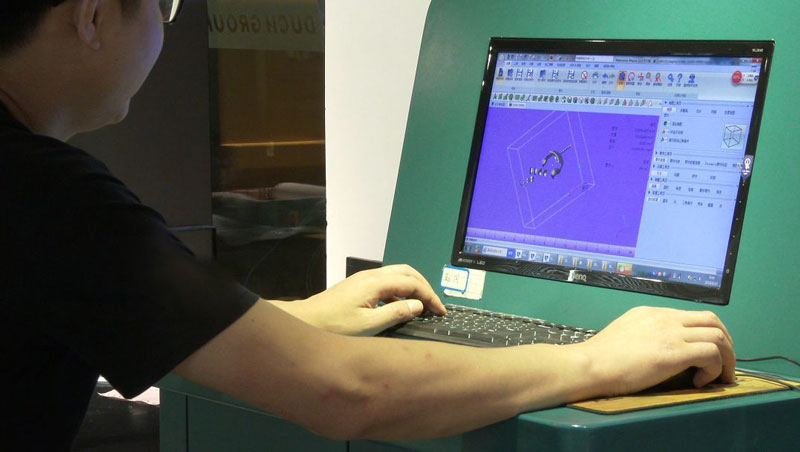

2. Import the file into the software for slicing

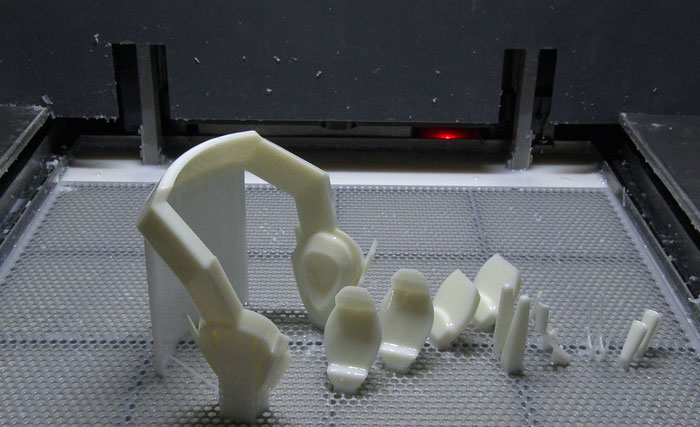

3. Print on the machine

The outer shell of this pair of headphones is completely printed by HXC's 3D printer, which has excellent surface printing quality and fine printing effect, and the printing effect of the headphones is also up to expectations.

Printing material: high-strength and high-toughness white photosensitive resin material, high precision, smooth and delicate surface, easy to post-process

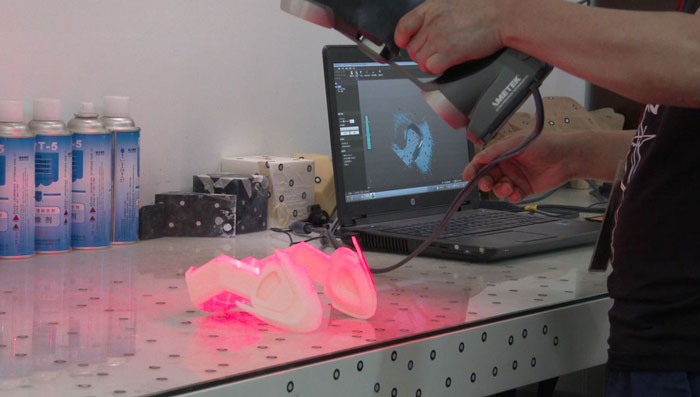

4. 3D scanning: Check the overall matching of printed parts

5. After the inspection is completed, the printed parts are subjected to exquisite post-processing

HXC can fully support customer customization needs. Different colors can be selected for each part of the headset, and even the shape of the earmuffs can be selected according to your preference.