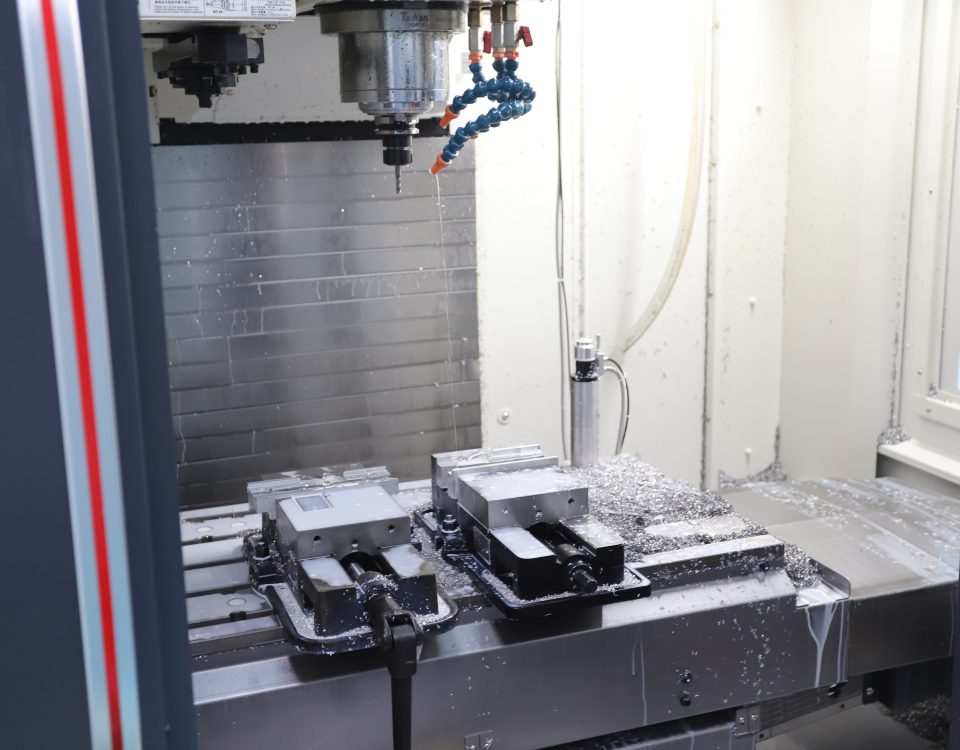

5-axis CNC machining center

2024-10-19

Agricultural Solutions

2024-10-21

ABS CNC machining details

ABS or Acrylonitrile Butadiene Styrene is a thermoplastic material that combines the different properties of PS, SAN and BS and is widely used in many industries. ABS is cost-effective, good processability and excellent mechanical properties, and is widely used in consumer goods and also has important applications in the automotive industry.

ABS CNC machining is a fast process for creating prototypes and end-use products. It not only saves costs because it does not require expensive injection moulds but also ensures that parts are manufactured and shaped accurately. Cnc-machined ABS parts are ideal for class production parts that require detail and tight tolerances. In this article, we will discuss the content of ABS CNC machining.

What is CNC Machining ABS?

CNC machining ABS involves removing excess material and performing cutting, turning or milling operations as needed to obtain the desired end product in its final form by utilizing computer-controlled digital technology. This can be programmed to specific requirements by mechanical tools. CNC machining of acrylonitrile butadiene styrene is an economical way to generate custom shaped parts without expensive molds, making it an excellent choice for prototyping and small series production. In addition, CNC-machined ABS show excellent rigidity, toughness and shock absorption, especially considering the relatively low cost of the material.

What are the benefits of ABS CNC machining?

There are many advantages to using ABS in CNC machining projects. CNC machining eliminates the need to create molds, making it a cost-effective way to manufacture parts with complex geometry at favorable prices and precision tolerances. In addition, ABS has strong mechanical properties and high impact strength. It also has excellent electrical insulation and can adapt to a variety of environments. In addition, ABS has a range of remarkable properties, such as high chemical resistance, impact strength, hardness and commendable dimensional stability.

It has high impact strength and considerable surface hardness in a relatively wide temperature range, and is a resin with good comprehensive characteristics and excellent dimensional stability than PVC and PA and ABS.

ABS has impressive mechanical properties, such as excellent impact strength, enabling it to be used at extremely low temperatures.

ABS has excellent electrical insulation and is virtually unaffected by changes in temperature, humidity and frequency, making it suitable for use in a variety of environments.

ABS resists the harmful effects of various substances, such as water, inorganic salts, bases, alcohols, hydrocarbon solvents and many acids. However, it is prone to stress cracking due to degradation caused by vegetable oil and glacial acetic acid.

ABS CNC machining applications.

CNC machining is ideal for producing a range of end-use parts and prototypes made from ABS. ABS is used to manufacture frames, housings, gears, instrument panels, dashboards, seat backs, vacuum cleaners, toys, and several other products. ABS CNC machining is used in various industries including medical, automotive, electrical and construction industries.

CNC ABS processing FAQ

What is ABS?

ABS is known for its excellent machinability, high impact strength and toughness, elasticity, and is a popular thermoplastic material used in CNC machining, 3D printing, and injection molding, especially for prototyping applications. CNC machining ABS is the perfect solution for projects where mechanical properties and details are important, including collaborative testing, conceptual modeling and functional prototyping.

Can ABS plastics be processed?

ABS plastic is an affordable engineering plastic that is widely used in prototyping and end-use products. For parts that require fine details and mechanical properties, CNC-machined ABS may be the right choice.

How to cut ABS plastic effectively?

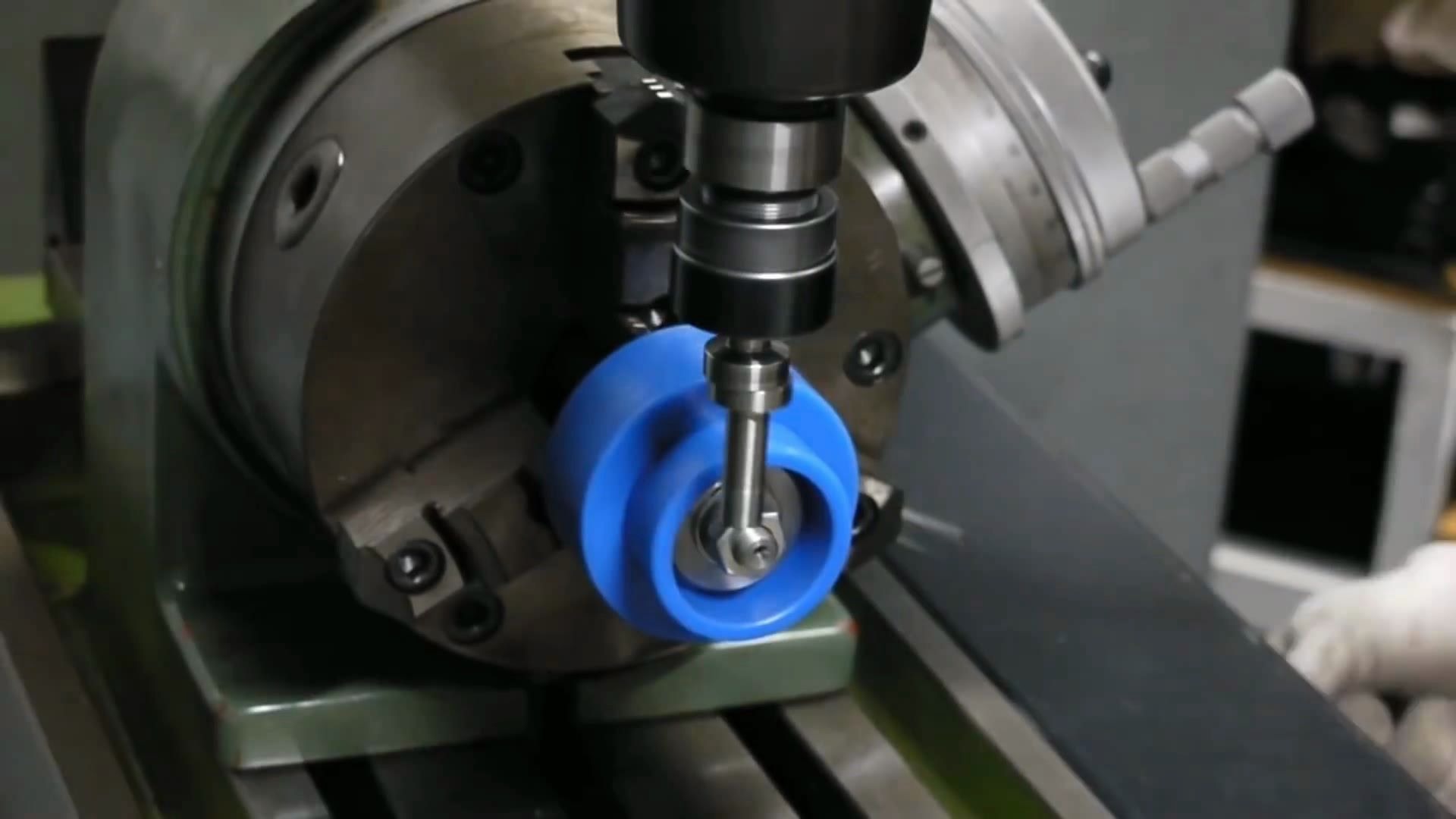

CNC milling technology can cut or carve ABS plastic, depending on the desired outcome of the project.

How to fix ABS firmly on the milling machine body?

For thinner sheets, Scotch Permanent double-sided tape is the right choice, while for thicker sheets and blocks, high-strength double-sided tape is recommended. However, the use of hot glue should be avoided, because ABS is easy to melt and will be deformed by heat, which is what makes it suitable for vacuum forming.

What should we pay attention to when processing ABS?

ABS operates efficiently at most feeds and speeds while using smaller tools. However, when using a large tool like 1/8 "end mill, it is essential to maintain a proper balance between the spindle speed and the material feed speed to prevent excessive heat generation, which can cause the chopped material to adhere to the bottom of the cut.

- Date

- 2024-11-05

- Date

- 2024-11-05