Innovative solutions for critical applications

Our long history in a wide range of markets has given us unique engineering experience, which we continue to use to innovate. Each of our products follows our manufacturing principles: high performance, high durability, and excellent reliability processed exactly according to the drawings.

Gear, worm gear, spline shaft, transmission parts processing expert

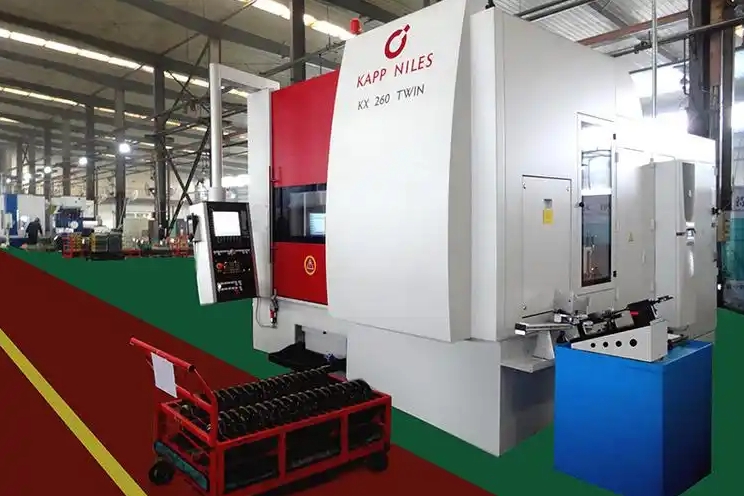

As an expert in machining production, hxc provides you with CNC turning, milling, precision grinding and honing, deep hole drilling and gun drilling, 5-axis CNC machining, CNC gear grinding, CNC gear milling, gear shaving, gear hobbing, spark machine and wire cutting, large gear processing and other machining services.

Our large machines include:

Various spur and helical gear cutting and hobbing machines

Internal gear hobbing machines

Keyway and spline/broaching machines

Various machines for special turning, milling, quenching, grinding, lapping and other precision gear processing.

Transmission parts, machining parts capabilities and range

HXC has invested a lot of technology and resources in the field of gear processing. Our machine tools are all imported equipment, and the grinding accuracy can reach the national standard level 4. We can provide large worm wheels with a diameter of 1400 mm, gears, and worms up to 5000 mm, gear shafts, spline shafts, planetary carriers, hubs, housings and other transmission parts.

Scope:

Precision machining, gear molding, mold injection technology

CNC hobbing, milling, shaving, symmetrical or asymmetrical gear grinding and polishing, forming grinding, non-guided spiral, inverted cone, convex surface processing, double spiral processing, gear cutting, broaching, etc.

Customized product center

Reducer gear

Precision copper worm

Precision Mechanical Gears

Reducer gear

Precision worm gear

Precision spur gears

Precision gears

Synchronous pulley

Helical gear shaft

Precision gears

Synchronous pulley