Electrical Discharge

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore eu fugiat nulla pariatur. Excepteur sint occaecat cupidatat non proident, sunt in culpa qui officia deserunt mollit anim id est laborum.

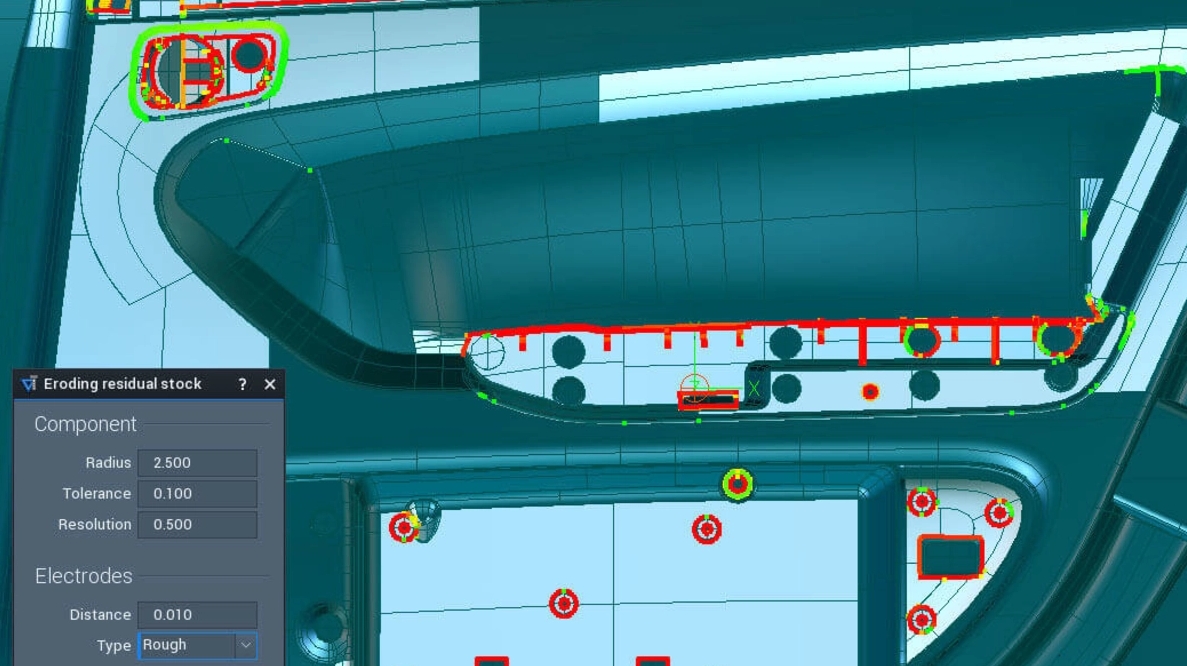

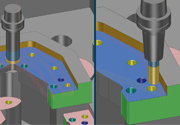

Automatic detection of areas to be processed by sinker EDM

Let HXC help you automatically search for all areas that still need to be machined after milling. The analysis before sinker EDM is based on the smallest milling tool used.

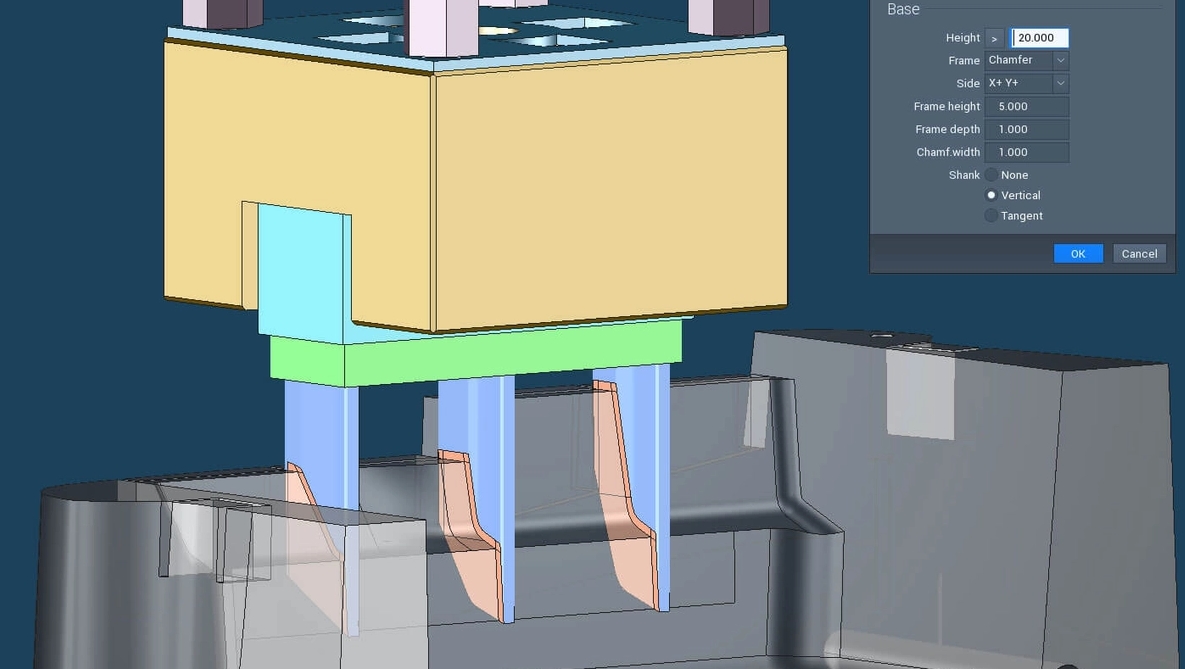

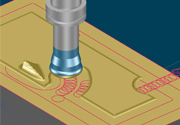

Quick assembly of complete electrodes

The discharge surface of the electrode can be processed according to the geometry with the click of a button. Use powerful interactive graphics to lengthen and complete the electrode. The wizard function guides the user in assembling a complete electrode for EDM forming - including the probe holder, base, pedestal and the necessary blank.

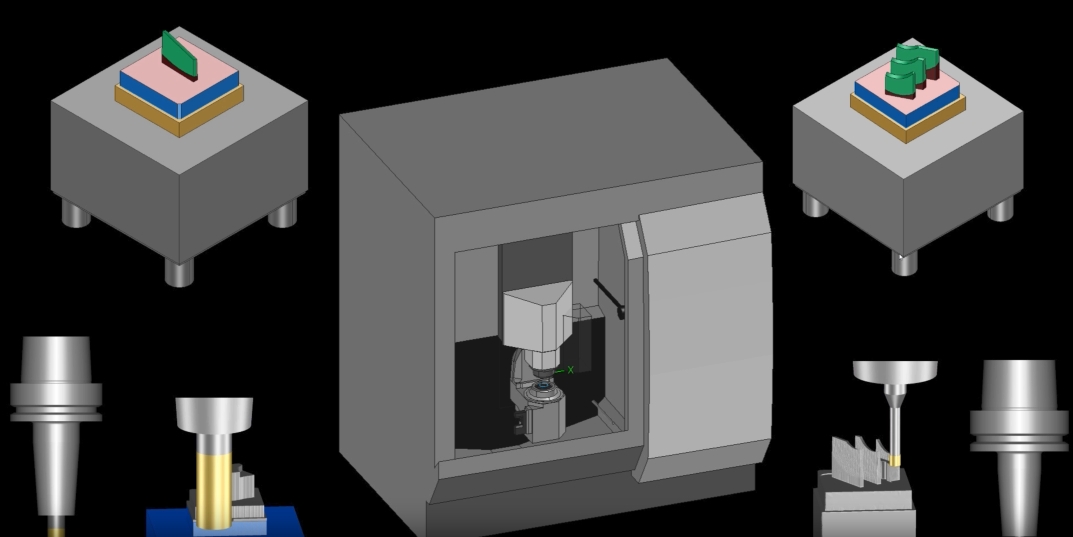

Optimized tool paths reduce manufacturing time

The structured design of the electrodes means that they are fully prepared for automated NC programming. This is achieved using individually prepared machining sequences stored in a process library and proven material removal strategies. Based on these strategies, the HXC automatically calculates the sequential CNC programs for roughing, finishing and residual material machining.

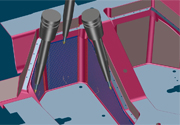

Integration management and processes

You can manage all information for sinker EDM in the clearly structured electrode management. In addition to electrodes, bases and blanks, this also includes the milling NC programs, EDM paths, measuring NC programs and the associated documentation. And if you want to achieve even greater intelligence – with flexible manufacturing cells for electrodes and EDM electrodes – all the necessary information for cell control is available in the electrode project. This ensures reliable, automated electrode processes.

Processing methods

More information on the EDM method

2.5D Milling

3D Milling

5-axis milling

Circular milling cutter

Slot milling