Magnesium Alloys: FAQ Guide

2024-11-05

Solutions for the automotive industry

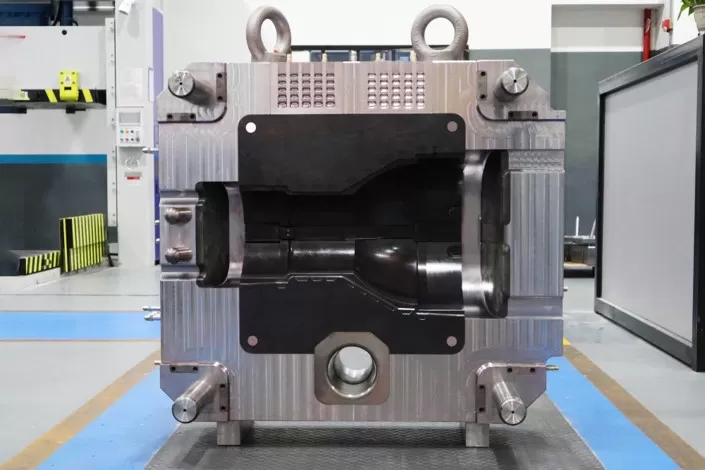

2024-11-05The entire process from design to mold trial for 1650T die - casting

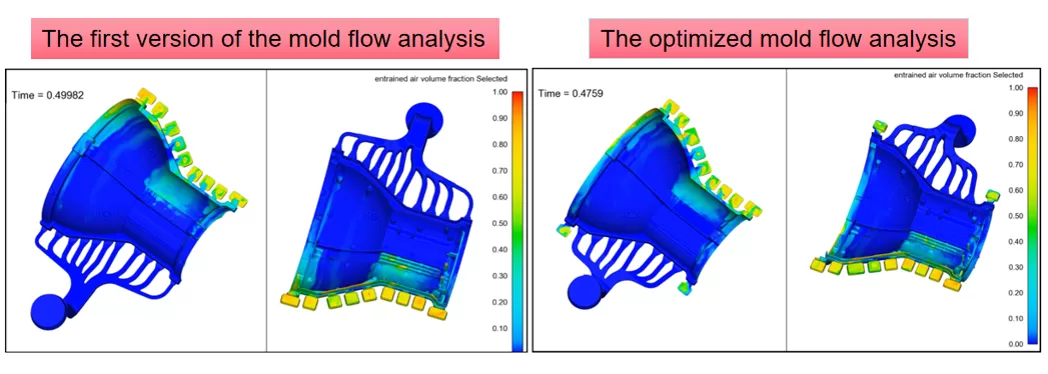

For each set of die-cast products, we will conduct more than two analyses of the gating system. Through comparison, we can find the most suitable solution.

For die-casting molds, machining accuracy is certainly important. However,The gating, slag removal, and thermal balance systems must be optimally designed to ensure process integrity.

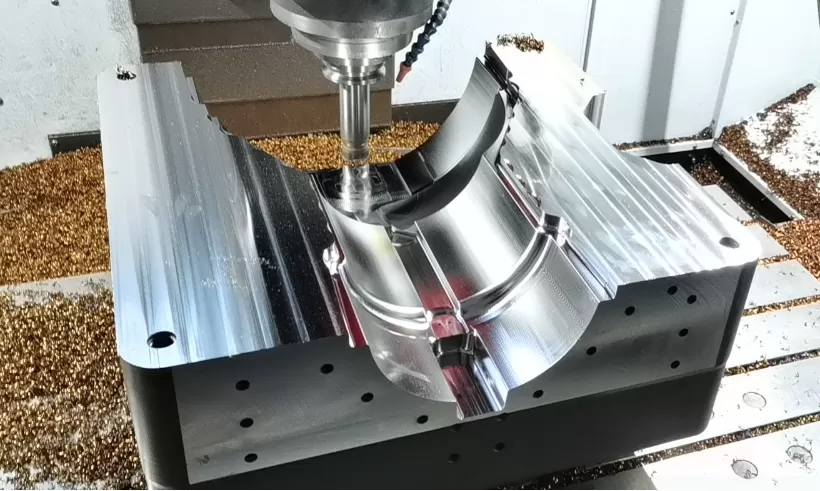

In terms of design, we conduct comprehensive research on the cooling channel system of the mold to ensure that the product is cooled quickly and evenly.

Upon receipt of customer approval for the mold design, we provide weekly manufacturing progress reports and process images to ensure real-time visibility into tooling production.

At HXC, depending on the complexity of the mold, the manufacturing cycle of our molds usually ranges from 25 to 35 days.

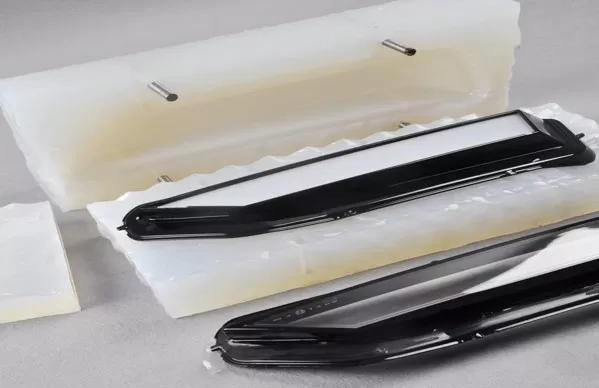

Mold Trial: Completely in accordance with the mold trial regulations, conduct a comprehensive inspection of the mold and the die-casting machine before the mold trial to ensure the smooth progress of the mold trial.

The site of mold trial, finished product display, attracting the attention of numerous clients