Tainless steel material cnc- one-stop parts processing

CNC machining stainless steel

Due to the special properties of stainless steel such as corrosion resistance and wear resistance, it has become one of the materials often chosen by engineers.

Common models of stainless steel are: Austenitic, martensite, 304, 303, 316, 420, duplex stainless steel, etc., different types of stainless steel physical properties are different, if your product needs non-magnetic and has high toughness and plasticity, but do not mind strength, it is recommended that you use austenitic stainless steel, if your product is food, it is recommended that you use stainless steel 316, HXC has more than ten years of CNC machining experience in stainless steel, when you are not ready to choose the material, please feel free to consult our online technical engineers.

What are the processing processes for CNC machining stainless steel parts?

Stainless steel density, high hardness, and no magnetic absorption, in the processing technology, clamping and tool selection will be different from other materials, general CNC machining stainless steel parts common processing technology are: CNC milling machine processing, CNC lathe processing, grinding machine processing, wire cutting, electric discharge, deep hole drilling. There are many new and precise processes, and engineers have ways to combine different processes to provide you with the ideal product.

What are the surface treatments of CNC machining stainless steel?

Usually we will think that stainless steel will not be oxidized, corrosion, so there is no need to do any surface treatment, it is wrong, stainless steel in a certain environment, too long time will be oxidized, corrosion, but the speed is not faster than other steel parts.

In order to protect products, prevent oxidation, corrosion, improve product life and identification, we provide customers with processing + surface treatment services for a long time, usually CNC stainless steel after the common surface treatment are: grinding, polishing, sandblasting, powder spraying, wire drawing, electroplating, radium carving and so on.

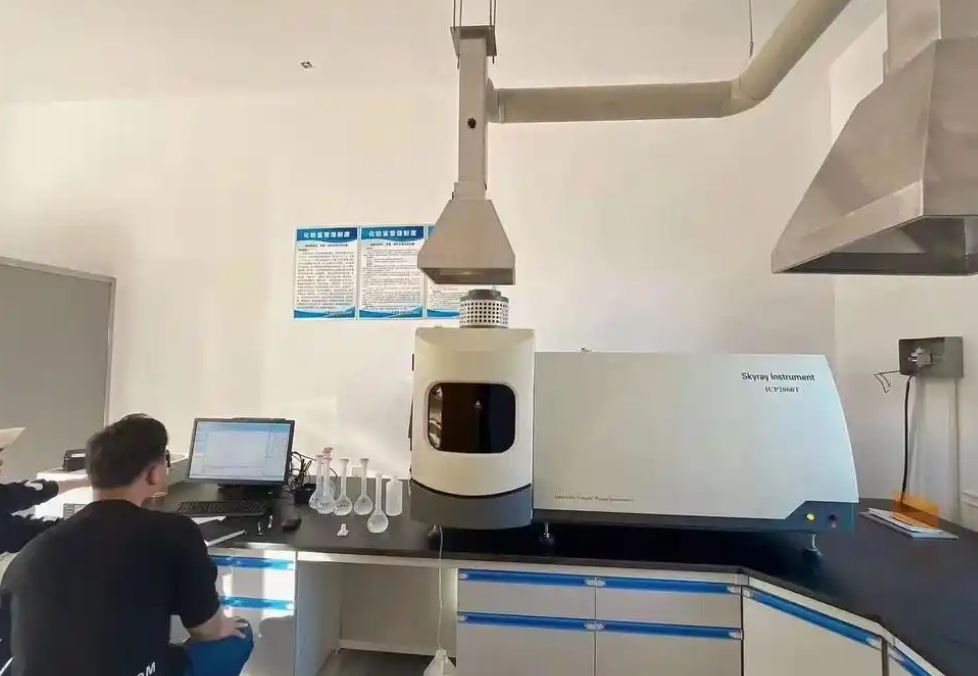

Analysis and detection

When you choose CNC machining stainless steel services, the selection of the material is very important, the supplier is more important to the material, each material can not be distinguished by the naked eye, different types of materials are different, in case the wrong material is used, it will cause serious impact on the use of customers' products.

More cases:

- Date

- 2025-03-08