Your Chinese die casting expert

HXC Die Casting:

Focused on the research, development, and production of die casting molds, we provide a complete set of die casting mold solutions, as well as peripheral tools for die casting molds, and offer a lifetime product service system.

Strong technical team - Front-end technology researchers and developers account for about 25% of our team, ensuring stronger service timeliness.

Technical expertise - We have focused on the overseas die casting mold market for many years and have mastered the technical characteristics of technically advanced regions such as North America and Europe.

Software diversification - We have established partnerships with multiple similar software companies both domestically and internationally to develop operational software suitable for our own characteristics.

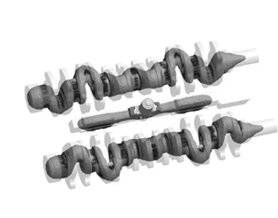

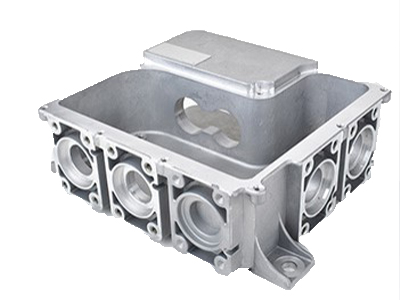

Die casting mold

Die casting production

Machining

Surface treatment

CAE Analysis

We utilize professional CAE (Computer-Aided Engineering) analysis software to conduct filling analysis on our products, simulating various potential scenarios including filling conditions, temperature, pressure, oxidation, air entrapment, and more. By identifying and addressing product molding defects in advance, before the mold is manufactured, we ensure that both the quality and efficiency of the product are guaranteed.

DFM Analysis

We optimize the products provided by our clients and assist them in making improvements by conducting a comprehensive analysis of the product materials, structure, surface requirements, mechanical properties, etc. This includes analyzing gate and sprue design, PL (parting line) design, ejection mechanism design, product optimization design, and more.

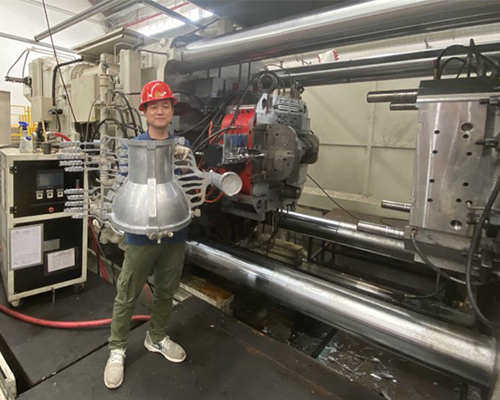

Advanced Die Casting Manufacturing

Die Casting Parts CNC Machining

Experienced engineer DFM the structure before tooling, CAM simulation the CNC route to ensure the allowance for post CNC machining.

Well designed CNC program to guarantee the the parts precision.

Based on your order quantity to choose the “smart” facility/technics to save your cost.

Responsible OQC will 100% inspect the parts, specially all the key dimension.

No worry about function, always 100% test before shipping.

In House Surface Treatment

Custom Die Casting

Parts for Any Industry

We think we can help you with our experience

Medical

Automotive

Home Appliance

Power tool

Aerospace

Electronic consumer

Robot

Mechanical

Check All Industries

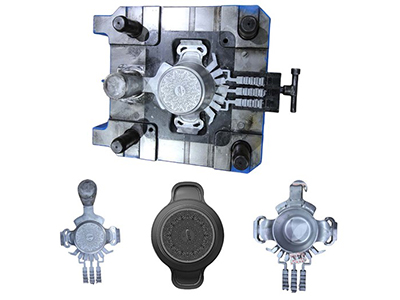

How We Control Your Parts Quality

With over 20 years of experience in die casting, we provide full process support for the design, manufacturing, mold trial, finishing, surface treatment, and finished product project control of each mold. By adopting the PPAP approach, we ensure the maximum delivery qualification rate of die castings.

- ISO9001:2008

- TS16949

- ISO13485:2016

- Density Testing

- ROHS

- Dimension Checking

- Chemical composition inspection

- Mechanical property test

- Insides defects inspection

- Cosmetic inspection

- Coating thickness test

- Saul spray test

- Surface smoothness inspection

- Color inspection

- Melting temperature monitoring

- Al chemical composition inspection

- Die casting equipment parameter monitoring

- FQI dimension

- FQI Cosmetic

- IPQC

- X-ray inspection of special parts of castings

Die casting case

Factory Certification

- Die Casting Benefits

- Die Casting Alloy Process

- Die Casting Process

- Die Casting Surface Treatment Guide