What can HXC's surface treatment services do for you?

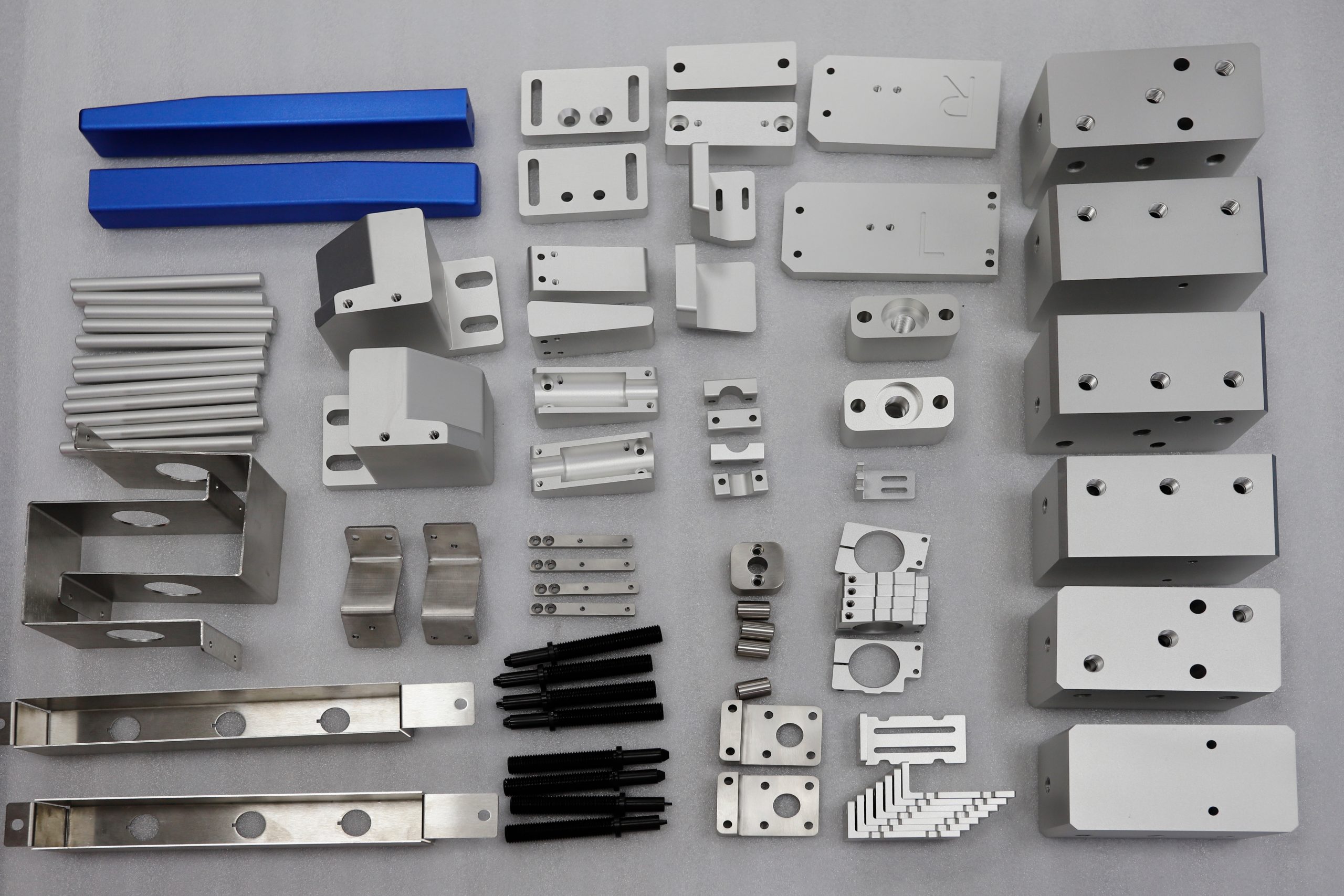

Your part was not truly completed before being handed over to our professional surface treatment department for processing. Whether it's metal or plastic, from single piece prototypes to complete large-scale production, we provide you with a package of services to polish your project to perfection.

A full range of professional surface treatment services

We don't just make parts. We take it a step further with a variety of treatments to improve appearance, performance and durability. Learn more about our key surface treatment services.

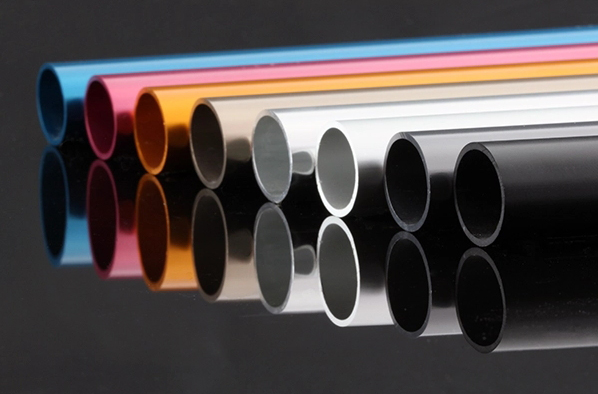

Anodic oxidation

HXC is an expert in aluminum, magnesium, or titanium anodizing. Anodizing helps to enhance the corrosion resistance of materials, increase surface hardness, improve wear resistance and heat dissipation. This is an ideal method for both spray painting and primer surface treatment, and the appearance after treatment is exceptionally exquisite. We typically use Type II anodizing, which allows us to add pigments or dyes to your parts to enhance their appearance. Type III can also be used for surfaces that require additional hardening.

Painting

Excellent painting is one of the best ways to make your product stand out. We only use the highest quality PPG automotive polyurethane, and in our constant temperature automatic paint booth, we can replicate almost any color, tone, or hue. Our spray paint experts can create millions of colors to achieve matte, flat, semi gloss, or glossy effects.

Soft touch coating

.Soft touch paint coatings can be applied to almost any surface, whether plastic or metal. This type of coating has a matte anti slip texture that can suppress glare and hide fingerprints. Especially suitable for handheld controllers and front panels of consumer goods that are frequently touched.

The coating is transparent, so it will not change the color of the substrate. However, product developers should be aware that flexible coatings cannot replace genuine rubber or elastomer coated molded parts

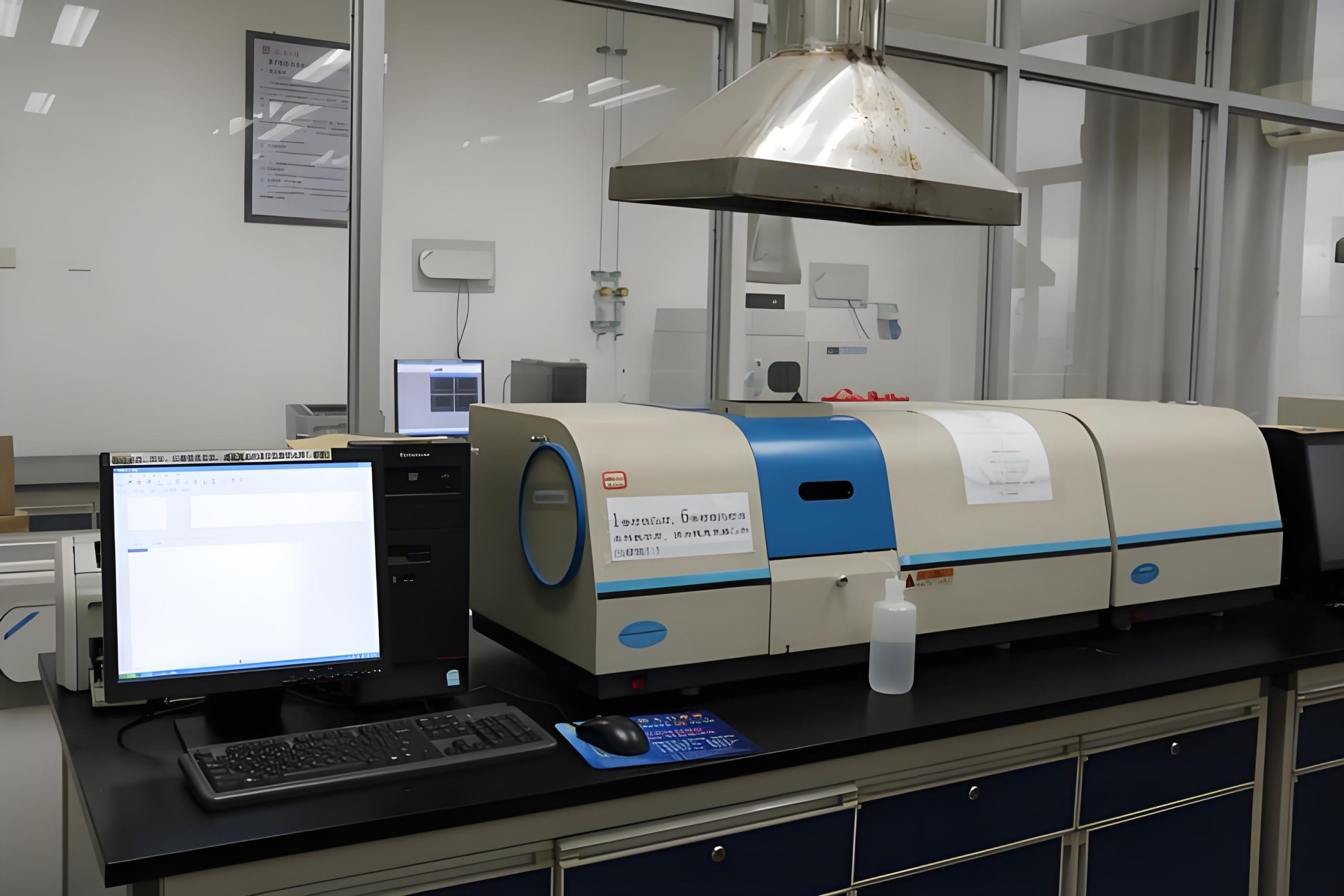

Color Match

Achieving perfect color matching may not be an easy task. That's why we use advanced spectrophotometers to accurately measure surface color, hue, and reflectance. This helps us match your color samples and ensure that the Pantone or other RGB colors we apply fully meet your specifications.

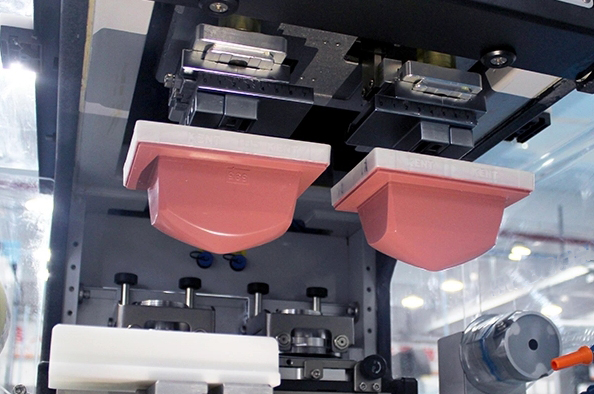

Transfer printing

Many products require the company's brand name or logo to be printed on the surface. How to achieve this? One method is to use transfer printing. Firstly, imprint the desired image onto a hard rubber block to create a seal, and then use the seal to imprint simple text and graphics on a flat or slightly curved surface. Pad printing has low cost and fast speed, but only one color can be used at a time.

screen printing

If you need more color options, or if you have a complex graphic to apply, screen printing may be the answer you need. Use a fine mesh screen during printing and cover a portion of the screen with the desired pattern. To apply more complex images or multiple colors, multiple different screens and templates can be used in a certain order.

Then squeeze the coating onto every area of the substrate surface that is not covered by the template through a grid. Through careful design, complex multi-color images, text, and colorful patterns can even be created on any hard surface. Screen printing is low-cost, versatile, and templates can be quickly produced. Is screen printing suitable for your project? Please contact us for more information.

Grinding and polishing

Grinding is not only used for paint preparation, but also for creating the final surface effect. We can achieve brushed and glossy effects on metal surfaces, as well as optical grade transparent polishing effects on transparent plastics. Hand sanding is also a very important part of vacuum casting technology, as the master mold must be carefully prepared before making replicas.

Steam polishing

Steam polishing is a special processing method used to manufacture optical grade transparent polycarbonate (PC) plastics. This method can also be used to repair smaller surface defects and is very suitable for achieving extremely clear and transparent surfaces in areas that cannot be reached by hand. This method requires the use of Weldon 4 gas to melt the plastic surface at the molecular level, thereby filling in fine scratches.

Sand blast

Sandblasting refers to spraying a certain type of abrasive medium onto a workpiece. Abrasives include sand, garnet, walnut shells, or high-pressure water. Abrasives are used to clean parts and remove burrs, while also preparing the parts mechanically and chemically for subsequent surface treatment. Sandblasting can also achieve unique textures, frosted textures, pebble textures, etc. View our blog for a detailed understanding of other commonly used metal surface treatment methods.