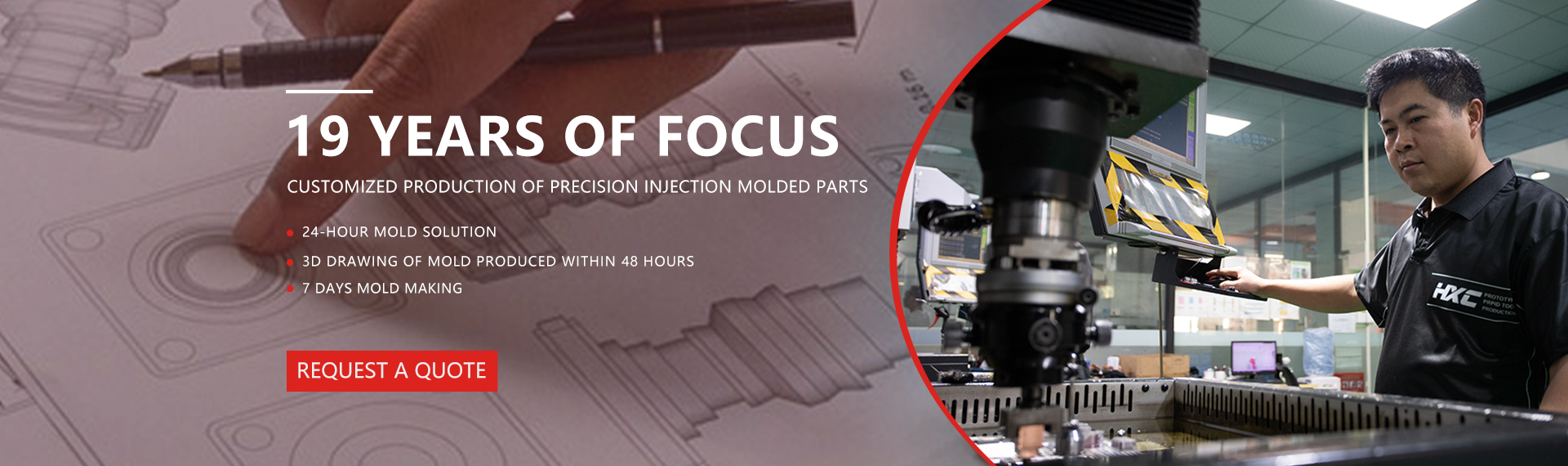

High-precision injection molded parts custom manufacturer

Customer-oriented, based on technology, adhering to the concept of service-driven growth, focusing on the customized processing of high-precision molds, providing one-stop OEM/ODM customized services including mold design, mold manufacturing, injection molding, and surface treatment. Over the past 19 years, HXC has been verified by the market and has always insisted on technological innovation, providing many companies with more precise molds.

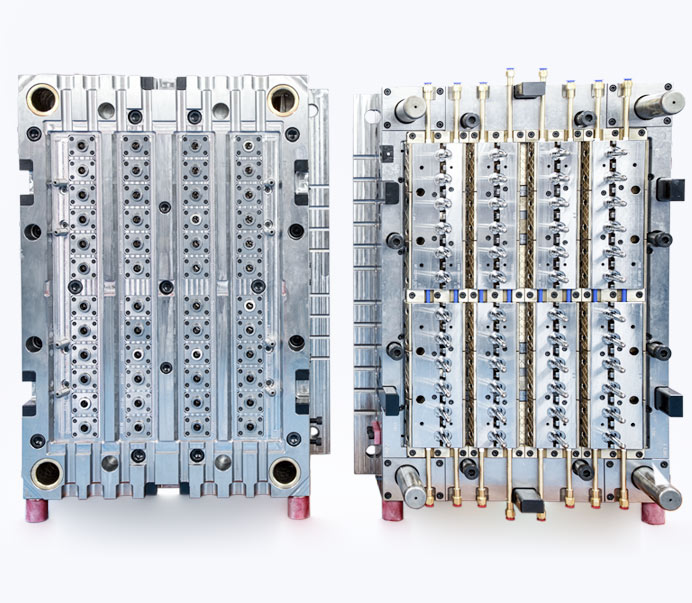

Mold manufacturing

The company has 5 German HERMLE 5-axis machining centers, 83 precision mold processing equipment such as AGIE spark machines, Sodick spark machines, Okuma, FANUC, etc., and a constant temperature and humidity production workshop. The processing accuracy can reach 0.002mm. The T1 pass rate exceeds 90%. More than 1,000 sets of precision molds are produced annually. 19 years of focus on precision molds, gathering sand into a tower, daring to take the lead, one-stop service to improve efficiency and ensure quality

Injection Molding

The annual mass production exceeds 30 million pieces. We focus on details, face difficulties, and provide professional assistance. We understand our customers best. The company has Sumitomo and Sodick molding injection machines, as well as dust-free injection molding processing workshops. The fully automatic manipulator can produce 24 hours a day, ensuring high efficiency, high consistency, and high-quality mass production.

The birth of precision injection molding

Understanding products is our core competitiveness

Demand Analysis

Defining, exploring, and quantifying customer requirements are the core of demand analysis. Important inputs include product 2D and 3D diagrams, product usage scenarios, and test requirements. However, these are far from enough and are only a small part of the iceberg. We use the IPD product development concept and multiple departments identify more hidden needs and constraints below the water surface from different dimensions.

Mold design

Special designers optimize the mold structure according to customer needs, strictly regulate the design process, and provide mold optimization solutions within 24 hours and mold 3D drawings within 48 hours.

Mould development

15 years of experience in the precision mold industry, covering medical, automotive, electronics, food, cosmetics and other fields, 20+ years of experience in the industry design team, excellent high-precision CNC and EDM processing equipment

Injection molding

It has a constant temperature and humidity dust-free injection molding workshop, 20T-400T Sumitomo and LK automatic manipulator injection molding machines to ensure high precision and high efficiency oxygen

Surface treatment

Polishing, oil spraying, powder spraying, sand blasting, anodizing, electroplating and other surface treatment processes to meet customers' personalized customization needs such as oil spraying and silk screen printing

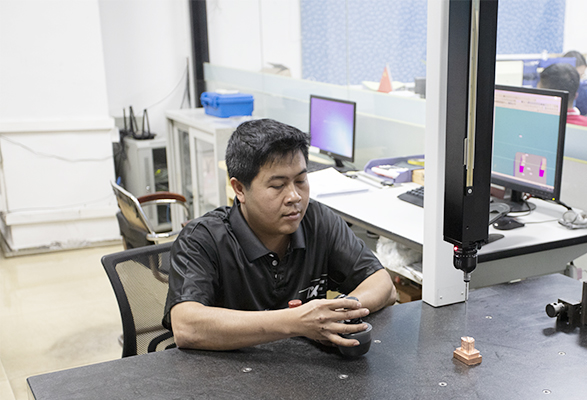

Detection assembly

A constant temperature workshop is set up, equipped with 3D scanner, 3D measuring instrument, 2.5D fully automatic image measuring instrument, X-ray fluorescence spectrometer and other testing equipment to ensure product quality.

Four core competencies

Fast delivery, guaranteed, strong technology, full service

Delivery Strength

100 sets of precision molds per month, mold manufacturing in 7 days 19 years of high-precision mold R&D experience, with a 15,000m² production base, 134 production equipment, a monthly output of 100 sets of precision molds, 48h prototypes, 7-day mold manufacturing, 24h injection molding proofing, and 24h mass production shipment.

Technical Team

The special design team with 20 years of industry experience has PMP certificate, municipal high-level talent certificate, and has obtained 20+ national patent certificates. It masters EDM technology, VDI standard surface texture, C-axis processing, CNC processing and other production processes. According to customer needs, it provides OEM/ODM customization services, with mold solutions within 24 hours, 3D drawings within 48 hours, and samples within 7 days.

Quality control guarantee

We have passed ISO90001 certification, strictly implement ISO9001, passed IATF16949 and ISO13485 medical certification, and have imported testing equipment such as German 3D scanners and Swedish 3D measuring instruments. The mold accuracy is ±0.002mm. The Kingdee ERP system controls the production process. Processing, measurement and assembly are all in the constant temperature workshop to ensure mold accuracy. The T1 pass rate exceeds 90%.

Service System