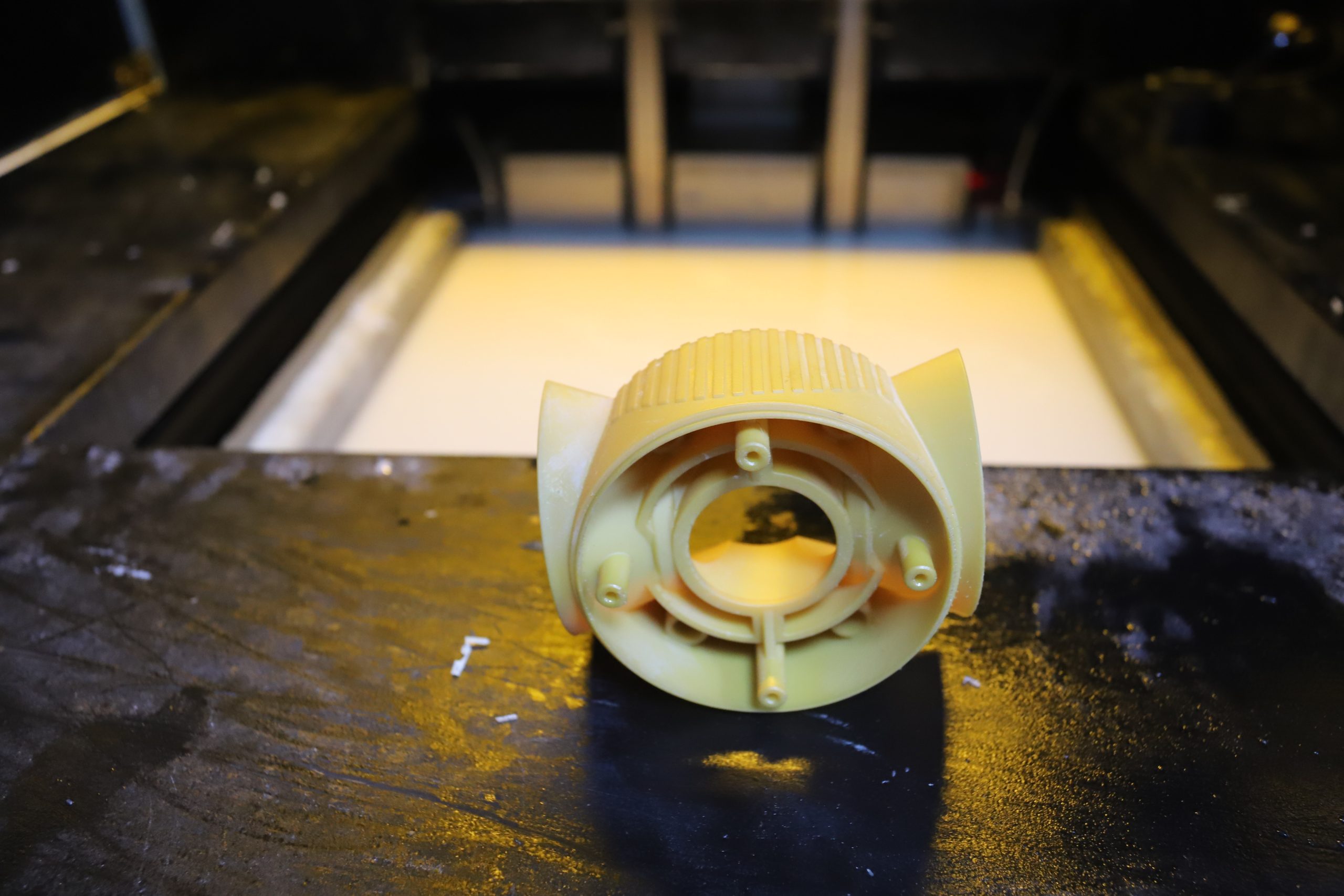

Mold manufacturing

- HXC's products cover the fields of automobiles, communications electronics, medical and personal care, medical consumables, smart homes, semiconductors, new energy, etc., focusing on the development of smart medical care, artificial intelligence, IOT and other fields, providing customers with customized manufacturing services for high-precision plastic parts.

- The company has 5 German HERMLE C22, C42, C62 5-axis machining centers, 83 precision mold processing equipment such as AGIE spark machines, Sodick spark machines, Okuma, FANUC, etc., and a constant temperature and humidity production workshop. The machining accuracy can reach 0.002mm. The T1 pass rate exceeds 90%.

Injection molding

The company has Sumitomo and Sodick molding injection machines, as well as dust-free injection molding workshops.

High-precision virus tube molds are produced on Sumitomo injection molding machines. Using fully automatic manipulators, each set of molds can produce 32 virus tubes every 18 seconds, and more than 150,000 virus tubes can be produced every day, providing a large number of support for the front line of the fight against the epidemic. Now, 48 virus tubes are produced in one mold, further improving production efficiency. Mastars, with its high-tech mold design, production technology and high-quality product quality, is working tirelessly to fight the epidemic in conjunction with Daan Gene.

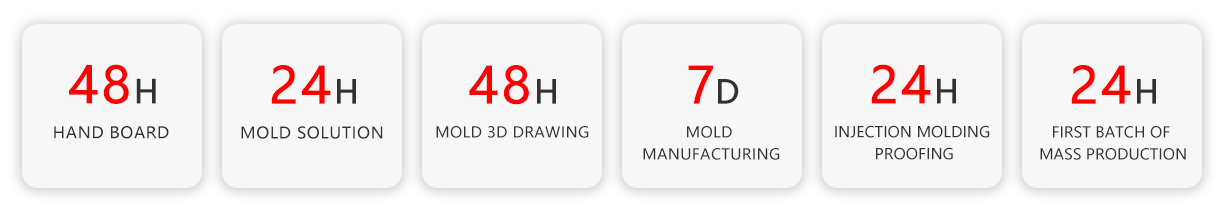

Delivery Capabilities