low pressure die casting

Let’s first look at low pressure die casting

What is low pressure die casting?

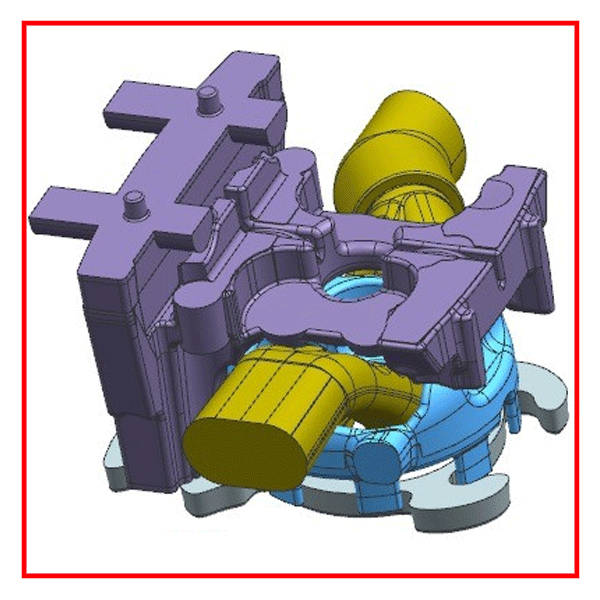

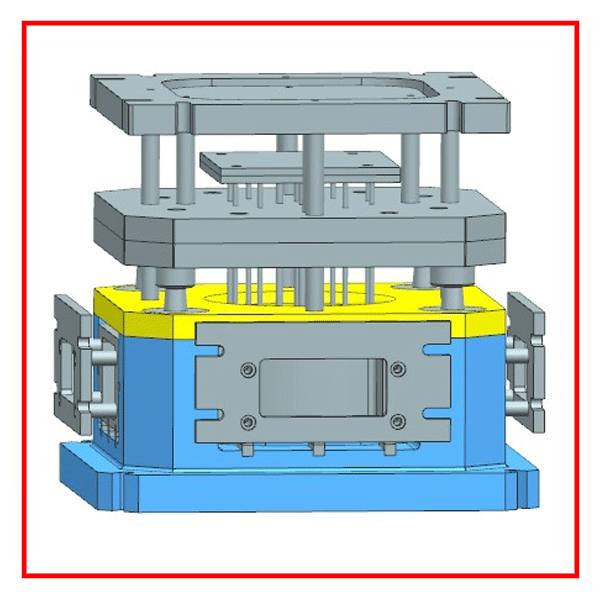

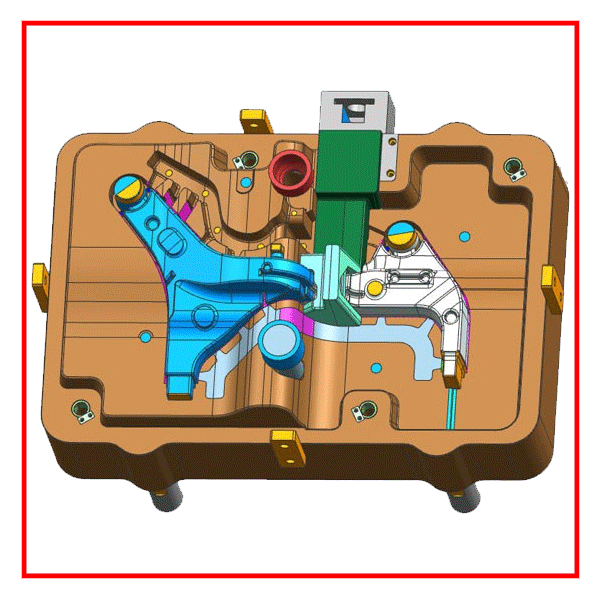

Low pressure casting is a method of filling the cavity with liquid metal under pressure to form a casting.

The process is: in a sealed crucible (or sealed tank), through the dry compressed air,Under the action of gas pressure, the metal liquid rises along the riser pipe, enters the mold cavity smoothly through the gate, and maintains the gas pressure on the liquid surface of the crucible until the casting is completely solidified.

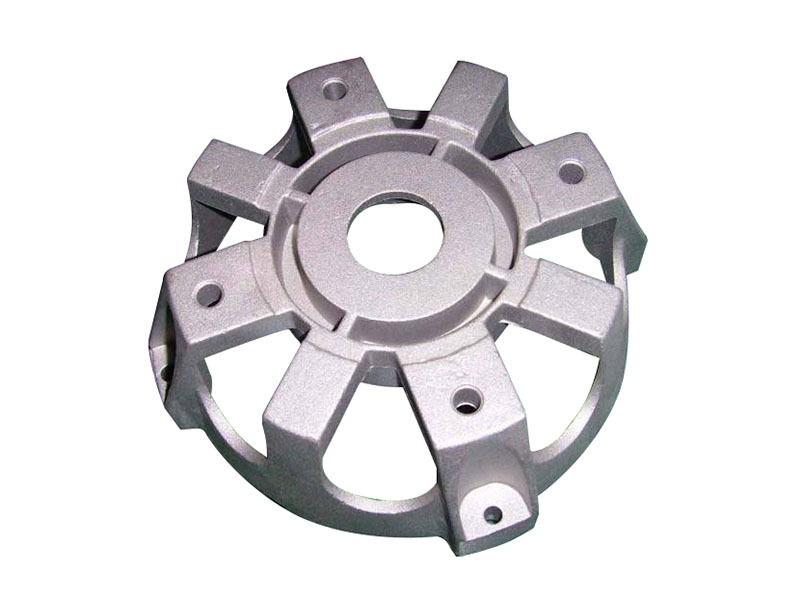

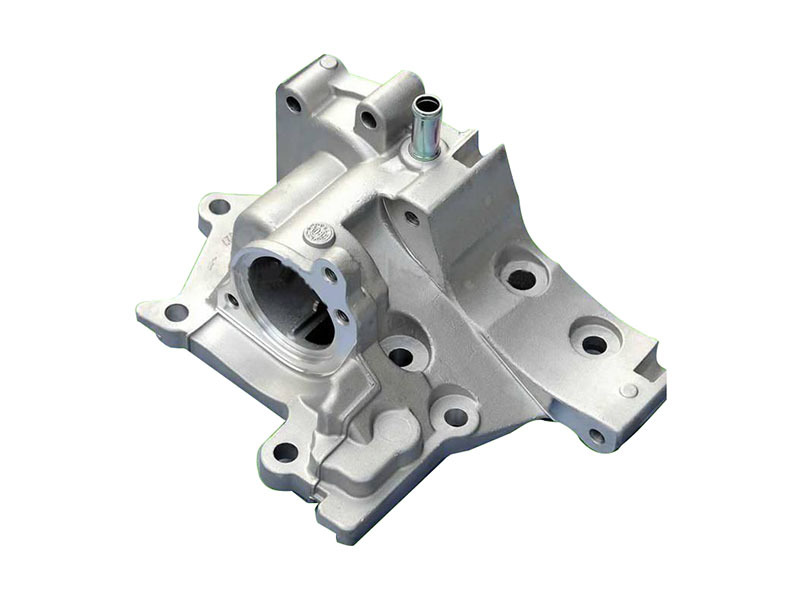

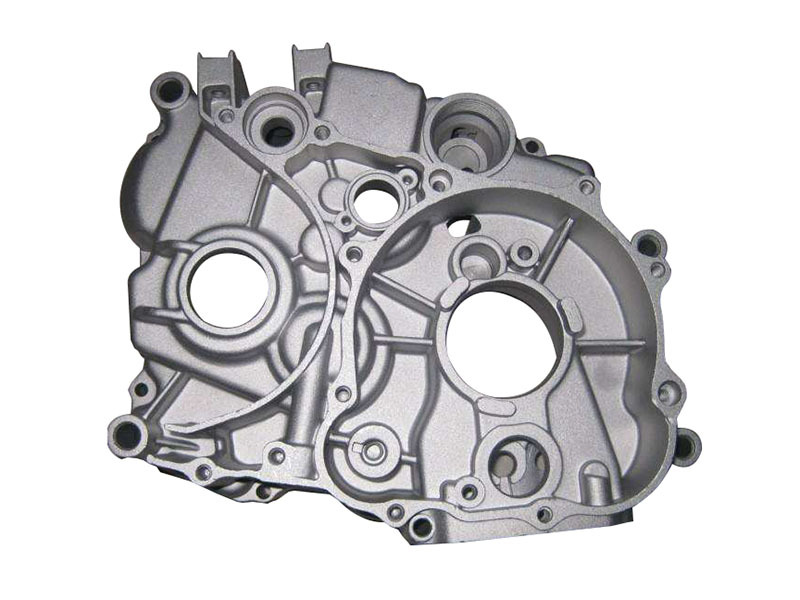

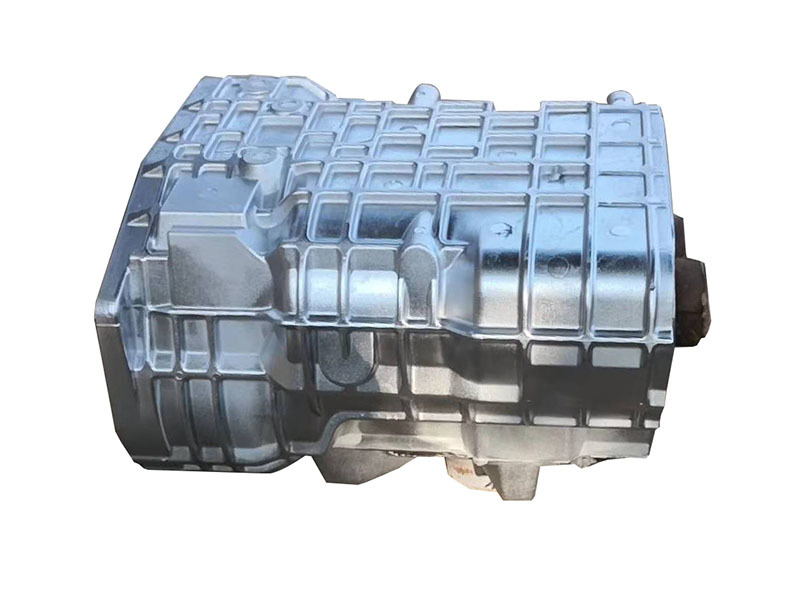

What can be done with low pressure die casting?

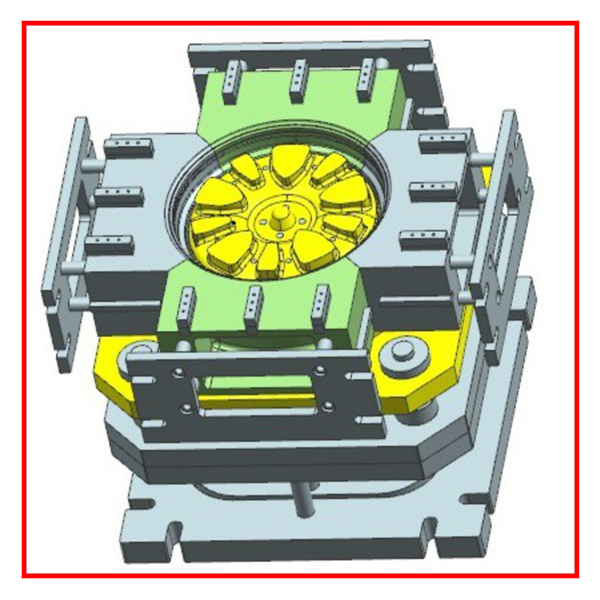

- Aviation field: Low pressure casting can be used for the manufacture of aircraft engine impeller, guide blade, turbocharger blade, turbine blade and other castings.

- Automobile manufacturing: Low pressure casting can be used for precision castings such as automobile engine shell, crankcase, cylinder head and inlet.

- Mechanical manufacturing: Low pressure casting can be used to manufacture hydraulic pumps, oil pumps, fan blades, transmission enclosures and other mechanical precision castings.

- Ship manufacturing: low pressure casting can be used to manufacture ship’s propeller, steering wheel, ship box plate, etc.