Die cast zinc alloy industry

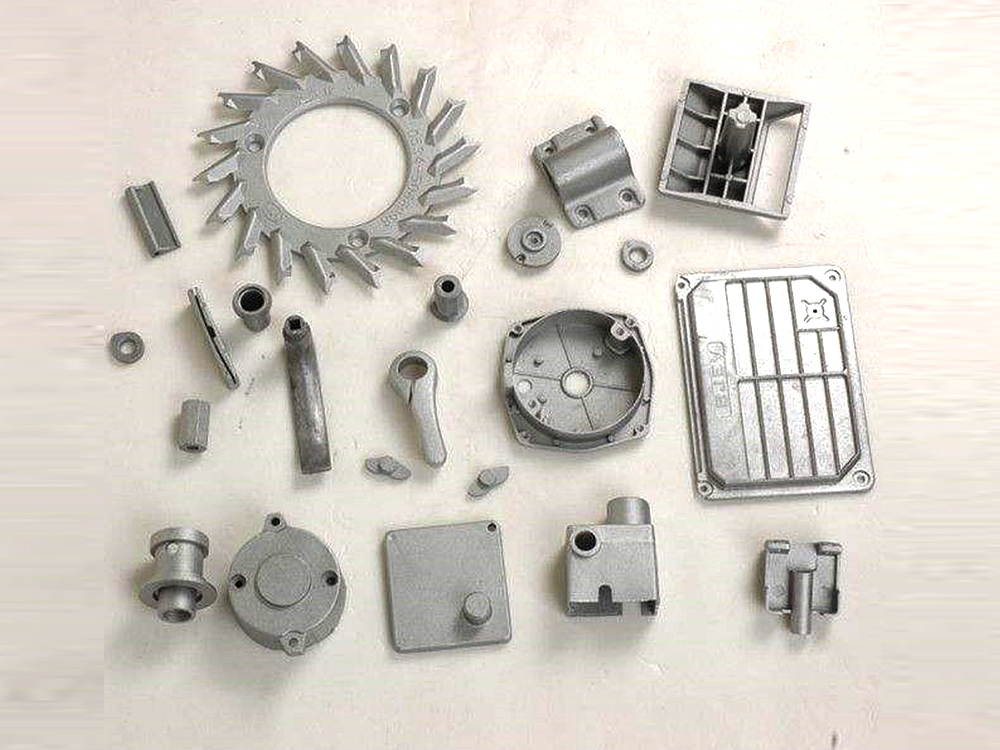

HXC is a world-leading company of zinc alloy die casting parts manufacturers. We’ve produced tens of millions of die casted Zinc products,Without outsourcing, we produce in house. The fast lead time can meet 2 days. We have strict quality control from mould manufacturing to part finish, and are equipped with corresponding finish and inspection devices. Our professional technical experts are glad to solve all kinds of difficulties in customers’ products for free. Contact us now!Zinc alloy is widely used in many industries, such as: automobile, household appliances, mobile phone, electronics, beauty equipment, kitchen electrical products…etc.

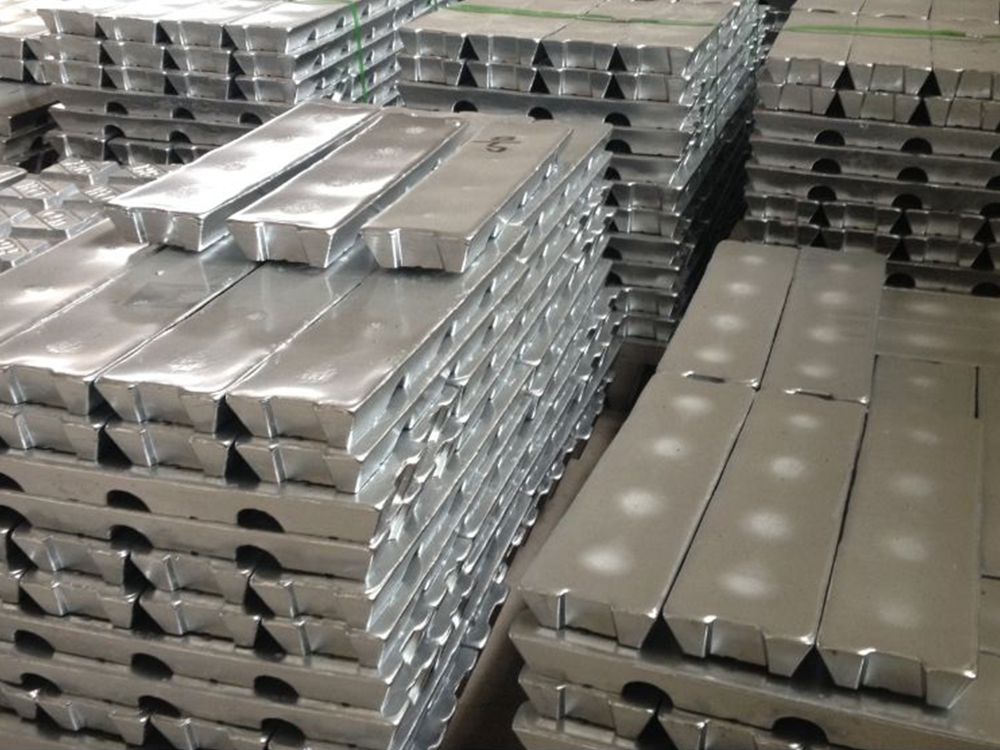

Zinc alloy has low melting point, and it melts when temperature meets 400℃. Zinc alloy is easy to mold in die casting. Zinc alloy doesn’t adsorb iron in the process of melting. Zinc alloy has good properties of casting, electrical conductivity, thermal conductivity, dimensional accuracy, stability, thin-walled ability, corrosion resistance, recyclable, high intensity and great hardness, besides, Zinc alloy costs low of raw materials, which makes Zinc alloy become the idea choice of replacing machining, pressing, stamping and assembling components. In the process of die casting, can make many intricately shaped precise components get smooth surface after die casting. Long term used Zinc alloy are: ZA-27, Zamak-2, Zamak-3, Zamak-5, Zamak-7, ZA-8, ACuZinc-5 .

ZA 27

Zamak 3

Zamak 7

Zamak 2

Zamak 5

ZA 8

HXC is the most professional company in Zinc die casting

As one of the best manufacturer of Zinc die casting in China,HXC provides one-stop service for custom Zinc die casted parts from engineering, mould making , Zinc die casting production, post finishing machining and surface treatment. We can provide our customers prototypes for Zinc die casting production, small batch production of Zinc die casting, and massive production of Zinc die casting. We’re really good at it!

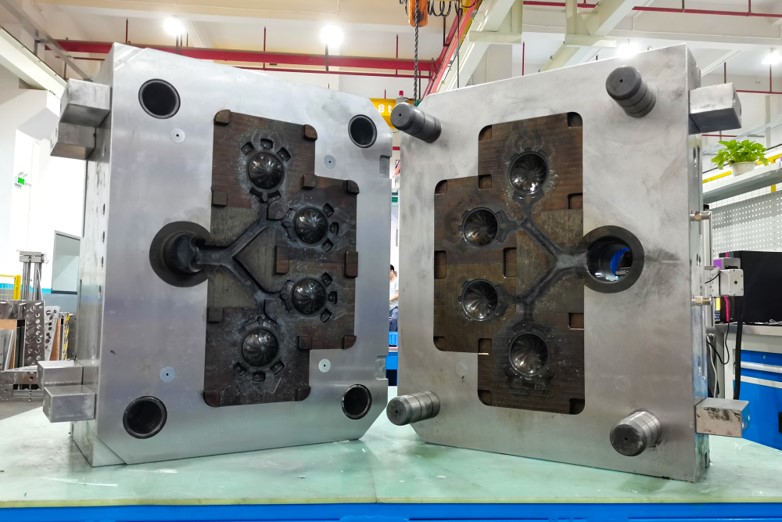

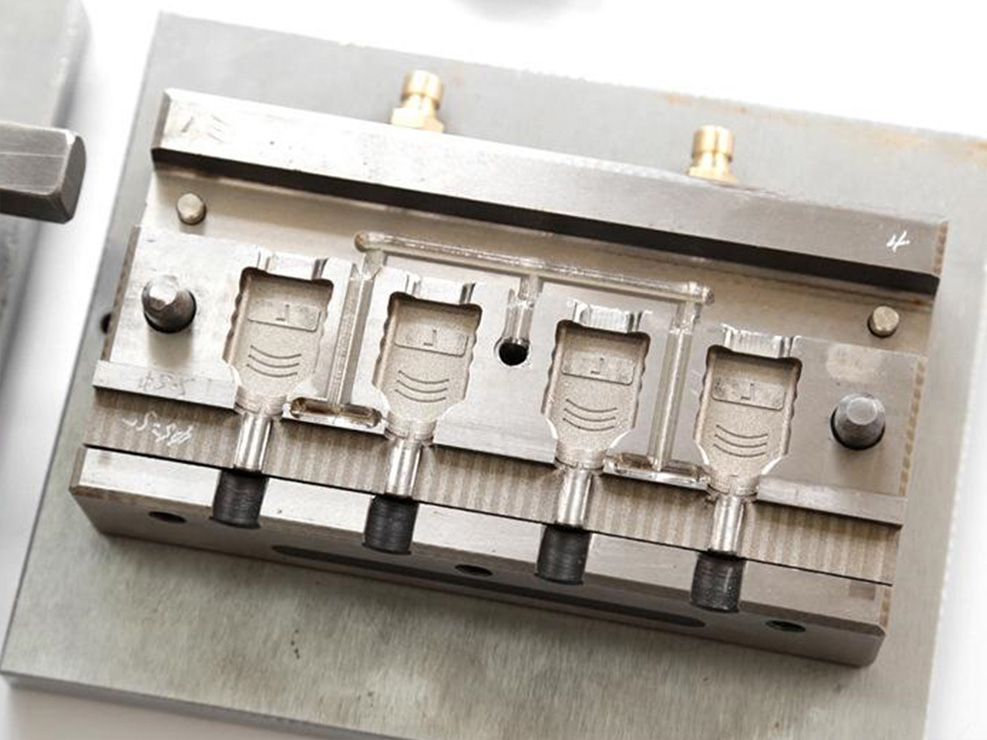

Mould for Zinc alloy die casting

Provide single cavity mould, multi-cavity mould,series mould, and also MUD mould base for smallbatch production of Zinc die casting.

Mould for Zinc alloy die casting

Provide single cavity mould, multi-cavity mould,series mould, and also MUD mould base for smallbatch production of Zinc die casting.

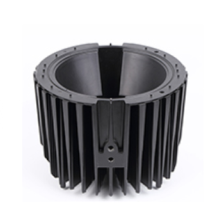

Surface treatment

Strong coating, electronic coating, chrome plate, glossy and matte finish.

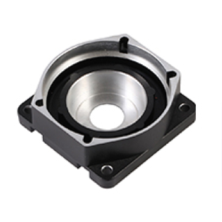

Post Machining

HXC is equipped with advanced CNC machining center, so we can do post CNC machining for dimensions require strict tolerance, to make specific components.

Zinc alloy die casting mold

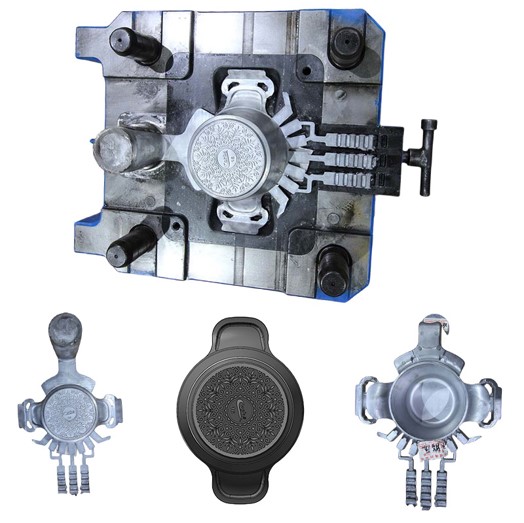

MUD mould base, we called female die. Female due suits for the low-volume production as it is based on modularization and can convert efficiently during process. It also saves time and cost because one mud mold base can operate two or two molds.MUD mould base HXC. We create a series of MUD mould base storage and prepare for coming projects. MUD mould bases are free of charge.

Family mould

Our multi cavity mold can produce parts share similarities in material and size, suiting for low-volume production. Our capacity can allow us to produce sophisticated zinc die cased parts in only one cycle. Family mould is a good choice for injection molding and die casting because it cost-effective in not only mold production but also die casting production.

Interchangeable cutter

We receive a 100-unit order from a customer who requested a small size 3-version zinc die casted parts with same outline and diverse knots for him. We suggest him to try the interchangeable insert, that is a mold consists with 3 different inserts which are geometrically different but quick and easy to assemble. After cast one version, we then replaced the inserts for another version.

HXC provides OEM service. If you have die casting projects from small to large batch of zinc die casted parts, please send your inquiry to Info@hxcmold.com today, and our sales engineers will get quotation back to you as soon as possible.