3D printing customizes racing-grade high-performance exhaust pipes for cars

2025-04-26

Prototype Model – Tesla Push Rod Case

2025-04-29Advantages of CNC precision parts processing in robot accessories

In the field of modern industrial manufacturing, CNC (computer numerical control) precision parts processing technology is playing an irreplaceable role in the manufacturing of robot accessories with its unique advantages. With the rapid development of robot technology, the requirements for the accuracy, strength and complexity of accessories are also increasing. CNC processing technology, with its high precision, high efficiency and high flexibility, perfectly meets this demand and has become one of the core processes in the manufacturing of robot accessories.

1. High precision: ensuring the accuracy of robot accessories

CNC machining technology can achieve micron-level machining accuracy through precise computer control of machine tools, which is difficult to achieve with traditional mechanical machining methods. In the manufacturing of robot parts, high precision is the basis for ensuring stable performance and precise movement of robots. For example, key components such as robot joints, bearings and transmission components have extremely high requirements for machining accuracy. CNC machining technology can ensure that the dimensional tolerances of these components are controlled within a very small range, thereby ensuring that the robot has a high degree of stability and accuracy during operation. In addition, CNC machining can also achieve fine control of the surface roughness of components, reduce friction between components, and improve movement efficiency and service life.

2. Consistency and mass production

In mass production, it is crucial to maintain product consistency. CNC machining technology controls machine tools through preset programs, which can maintain the consistency of component quality and specifications in mass production, effectively avoiding errors caused by human factors. This is especially important for robot parts manufacturing, because the performance and size of each part must strictly meet the design requirements to ensure the performance and stability of the entire robot. At the same time, CNC machining technology can also achieve rapid mold change and automated production, greatly improving production efficiency and output, and reducing production costs.

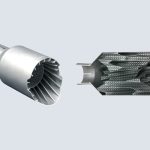

3. Complex geometric shape processing capability

Robot parts often have complex geometric shapes and structures, which places extremely high demands on processing technology. CNC processing technology can achieve efficient processing of complex geometric shapes through multi-axis linkage and complex programming. Whether it is the robot's main frame, joint structure or end effector, CNC processing technology can easily cope with it, ensuring that every component meets the design requirements. This capability not only improves the overall performance of the robot, but also expands the application field of the robot, enabling it to play a role in a wider range of industries and service fields.

4. Wide adaptability of materials

Robot parts often have complex geometric shapes and structures, which places extremely high demands on processing technology. CNC processing technology can achieve efficient processing of complex geometric shapes through multi-axis linkage and complex programming. Whether it is the robot's main frame, joint structure or end effector, CNC processing technology can easily cope with it, ensuring that every component meets the design requirements. This capability not only improves the overall performance of the robot, but also expands the application field of the robot, enabling it to play a role in a wider range of industries and service fields.

With the continuous development of robotics, the demand for customization is increasing. CNC machining technology can easily achieve customized production with its high flexibility and programmability. Whether it is special accessories customized according to customer needs or optimized designs for specific application scenarios, CNC machining can provide reliable solutions. HXC's CNC machining has rich industry experience and expertise, and can provide customers with a full range of technical support and after-sales services to ensure that problems encountered by customers during use are solved in a timely manner.

6. Wide range of applications

The application field of CNC precision parts processing in robot accessories manufacturing is very wide. From industrial robots to service robots, and then to medical robots, CNC processing technology plays an important role. In the industrial field, the high precision and high efficiency of CNC processing enable robots to achieve efficient and stable operation on automated production lines; in the service field, CNC processing technology can manufacture lightweight and high-precision parts to meet the special needs of household robots and medical robots; in the medical field, the high precision and reliability of CNC processing ensure the safety and effectiveness of surgical robots during surgery.

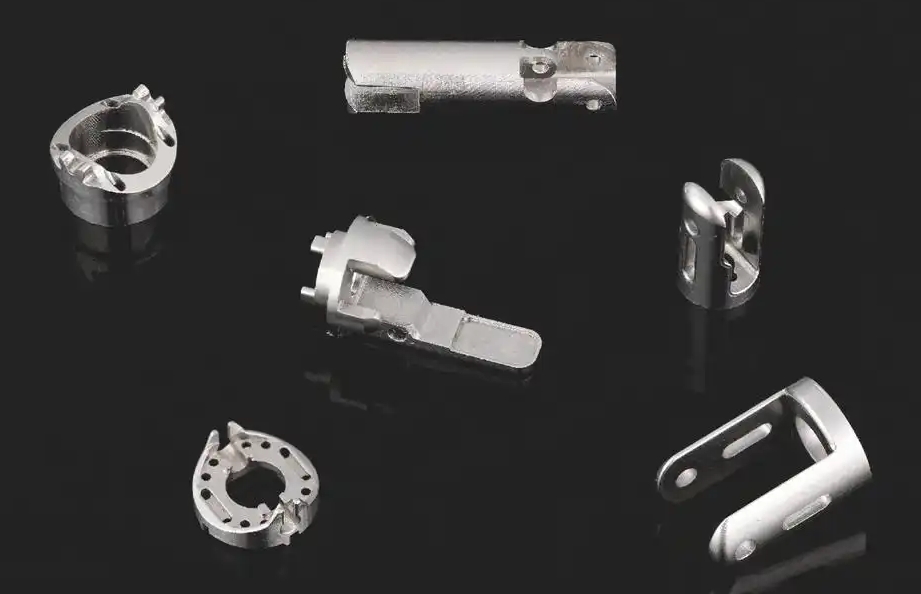

7. Case Analysis: CNC Processing of Surgical Robot Parts

As a high-end product in the medical field, surgical robots require extremely high precision and reliability of their accessories. Taking the da Vinci surgical robot as an example, its accessories include multiple movable robotic arms, high-resolution optical imaging systems, terminal surgical tools, sensors and control systems, etc. CNC processing technology is widely used in the manufacturing process of these accessories. Through CNC processing, high-precision processing and heat treatment of robotic arm joints and bearings can be achieved to improve the precision and strength of parts; at the same time, complex optical imaging systems and sensor housings can also be manufactured to ensure the stability and accuracy of surgical robots during surgery. In addition, CNC processing technology can also achieve rapid mold change and mass production of accessories, reducing production costs and cycles.

In summary, CNC precision parts processing has irreplaceable advantages and broad application prospects in the manufacturing of robot accessories. With the continuous development of robot technology and the continuous expansion of application fields, CNC processing technology will play a more important role in the manufacturing of robot accessories. In the future, with the further integration and development of intelligent and automated technologies, CNC processing technology is expected to achieve a higher level of automation and intelligent production, injecting new impetus into the development of the robot manufacturing industry. At the same time, we also look forward to the emergence of more innovative technologies and solutions to jointly promote the advancement of robot technology and the expansion of application fields.