Case Study of 3D Printer Production of Cupping Injection Mold

2025-04-26

Advantages of CNC machining robot parts

2025-04-29HXC's 3D printing technology customizes racing-grade high-performance exhaust pipes for Ford Mustang

The customer worked with HXC to print a car exhaust pipe using a metal 3D printer manufactured using MPBF TM technology. The exhaust pipe has been tested for assembly on a Ford Mustang sedan.

Case background:

For most commuters, the daily commuting process is unchanging. In order to avoid boredom and pursue personalized style, some car owners will make legal modifications to their cars within the scope of the law, such as customizing car exhaust pipes. However, due to the limitations of traditional welding processes, traditional exhaust pipe manufacturing faces the problem that the airflow design is too simple and the complex design is difficult to achieve. Moreover, in the current market, the airflow form of car exhaust pipes is mainly planned through plane design, which has problems such as poor airflow and power loss.

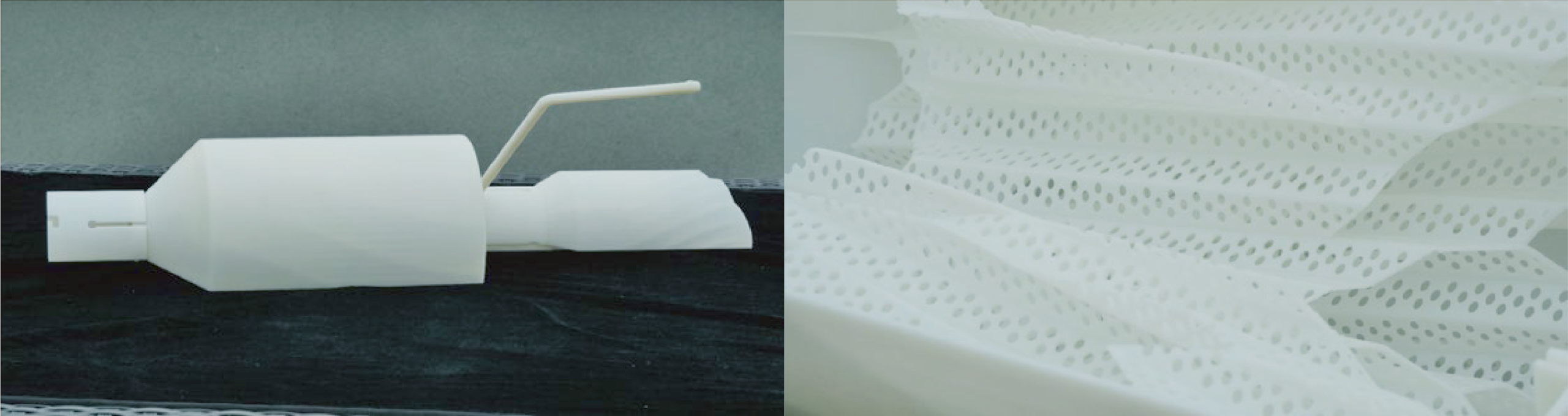

(Ford Mustang exhaust pipe designed and manufactured using traditional technology)

HXC has successfully customized a 3D printed car exhaust pipe for a car modification manufacturer. The exhaust pipe has now been assembled on a Ford Mustang.

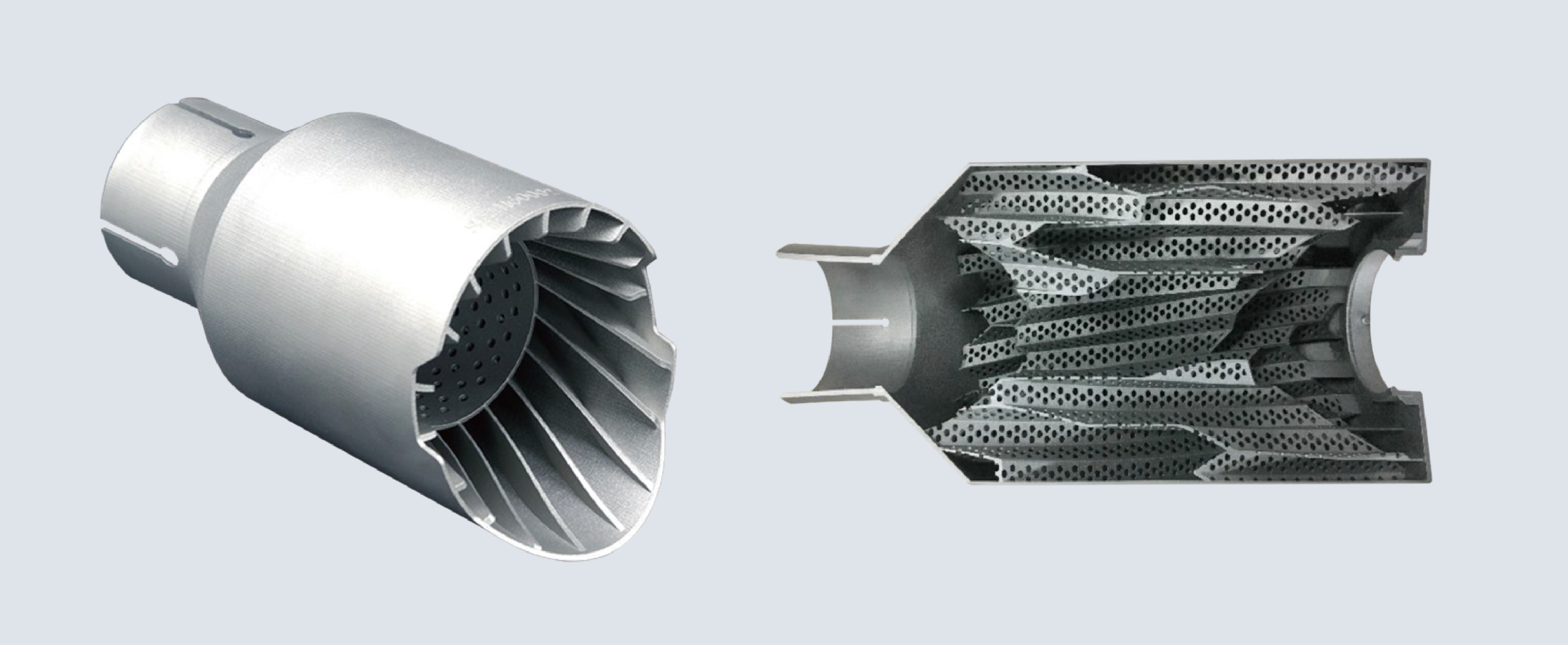

1. In the early stages of the project, HXC engineers designed a customized 3D model of the exhaust pipe in professional design software. During the design process, engineers used 3D printing technology to optimize the internal structure of the exhaust pipe, greatly improving the operating efficiency of the exhaust pipe and reducing the volume of the exhaust pipe.

3D model of custom exhaust pipe

The internal structure of the exhaust pipe is optimized using 3D printing technology, which is difficult to process with traditional methods.

3. After the design is confirmed by the customer, HXC uses multiple metal 3D printers to print together and place printing orders to HXC users distributed in various places. Multiple HXc metal 3D printers can print at the same time, greatly shortening the delivery time.

Advantages

1. Powerful sound

Through a more optimized structural design, the exhaust system manufactured by 3D printing has a stronger sound and sounds more like a supercar.

2. Reduce weight

The exhaust system manufactured by 3D printing has reduced its weight by about 67%. Although the weight has been reduced, the strength can fully meet the requirements, and the appearance of the exhaust system is also very beautiful.

3. Maintain power

When the car is driving at high speed, if the negative pressure exhaust pipe cannot discharge the exhaust gas in time, it will affect the power output efficiency of the car engine. The exhaust system manufactured by 3D printing has a specially designed exhaust duct with good exhaust efficiency. According to the exhaust speed of the car engine under different working conditions, and through the unique air duct design, the exhaust gas discharge efficiency can be reasonably arranged to ensure the power of the engine under different working conditions.

A new paradigm for 3D printing

In this project, HXC used 3D printing technology, which not only created value for users but also shortened delivery time.