Application of 3D Printing in Dentistry

2025-04-24

HXC Company discusses how to thin silicone products?

2025-04-25Adaptive Printing: Breaking through the Hardware Bottleneck of 3D Printing EVA Shoe Models

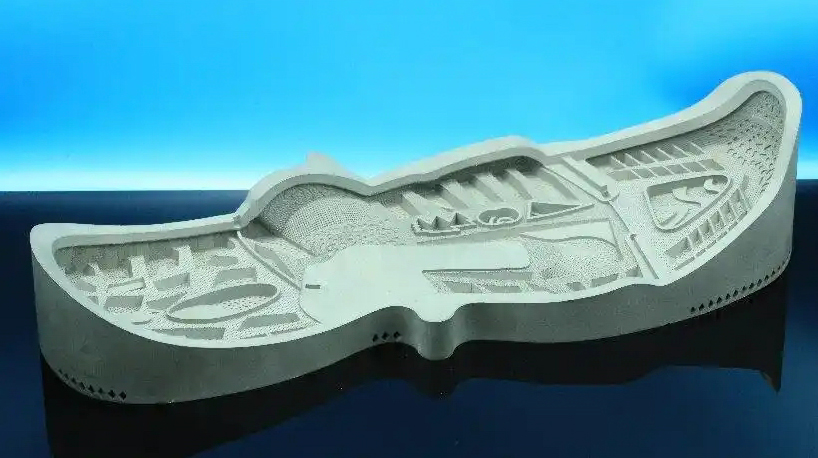

In the current booming development of 3D printing technology, its application fields are constantly expanding, from aerospace to daily consumer goods manufacturing, and its presence can be seen. In the footwear manufacturing industry, 3D printed EVA shoe molds, with their unique advantages, have brought higher customization and production efficiency to footwear production. However, when faced with complex EVA shoe mold printing tasks, printer hardware performance often becomes an insurmountable obstacle, and adaptive printing technology is like a ray of dawn, providing highly innovative ideas to break through this limitation.

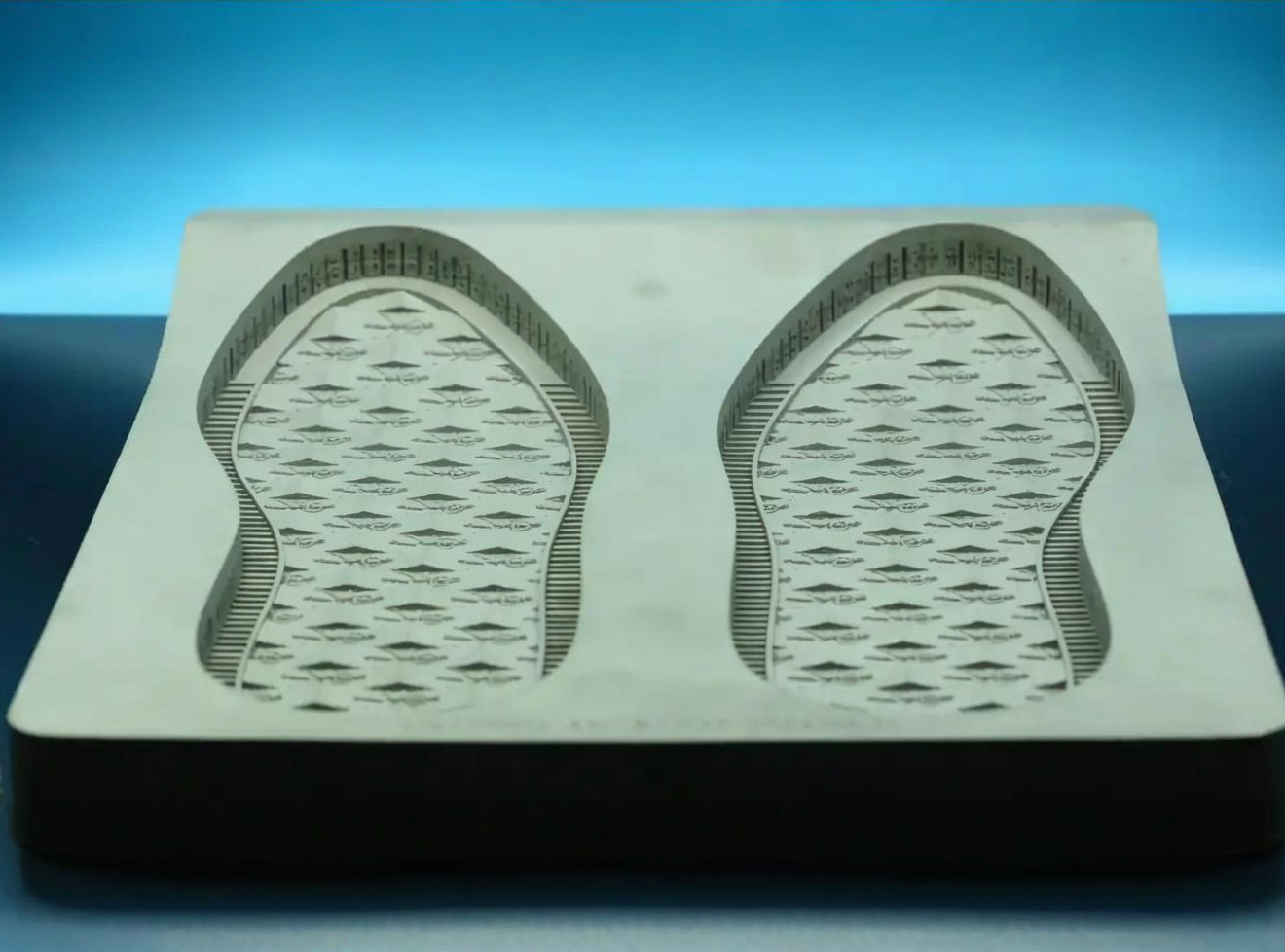

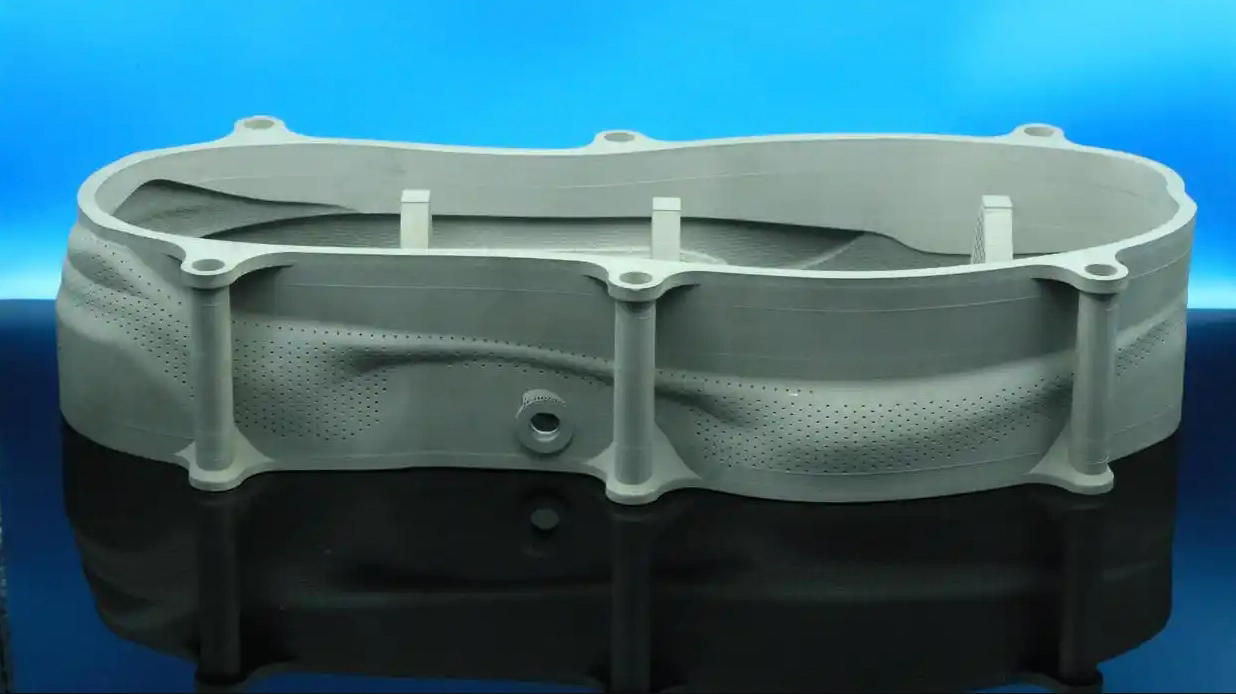

The hardware performance shortcomings of traditional 3D printers are exposed when printing complex structures of EVA shoe molds. The temperature control accuracy of the printer nozzle is limited, and the material extrusion amount is difficult to achieve absolute stability. The movement speed and stability of the motor are also affected by many factors. These issues may not be very obvious when printing simple structures, but once faced with complex EVA shoe molds, such as those with fine textures, special support structures, or internal hollow designs, they can cause a series of printing quality problems, and even lead to printing failures.

The adaptive printing system is like an intelligent "behind the scenes commander", which safeguards the printing process by monitoring various key parameters in real-time. The subtle changes in parameters such as nozzle temperature, material extrusion rate, and printer movement speed cannot escape its "eyes". Once parameter abnormalities are detected, the system will quickly respond and automatically adjust the printing strategy.

Imagine when the printer hardware encounters nozzle blockage or material extrusion obstruction while printing complex structures, the adaptive printing system acts like an experienced mechanic, taking swift action. It will automatically slow down the printing speed, giving the material more time to squeeze out the nozzle, while cleverly increasing the temperature and pressure of the nozzle. The increased temperature enhances the fluidity of the material, while the increased pressure further promotes the smooth extrusion of the material, ensuring that the printing process is not hindered and the printing quality is guaranteed.

During the printing process, the motor load of the printer is also a critical issue. If the motor is in a high load state for a long time, it will not only accelerate the wear of the motor, but may also lead to a decrease in printing accuracy. The adaptive printing system has a keen "perception ability", and once it detects excessive motor load, it will immediately take effect and automatically adjust the motion path. By optimizing the printing trajectory, reducing unnecessary motor actions, and avoiding the motor from bearing heavy loads for a long time, hardware devices are effectively protected and their service life is extended.

During the printing process, the motor load of the printer is also a critical issue. If the motor is in a high load state for a long time, it will not only accelerate the wear of the motor, but may also lead to a decrease in printing accuracy. The adaptive printing system has a keen "perception ability", and once it detects excessive motor load, it will immediately take effect and automatically adjust the motion path. By optimizing the printing trajectory, reducing unnecessary motor actions, and avoiding the motor from bearing heavy loads for a long time, hardware devices are effectively protected and their service life is extended.

In summary, adaptive printing technology plays an indispensable role in the process of 3D printing complex structures of EVA shoe molds. It enables 3D printers to more flexibly and efficiently meet the printing needs of complex structures under existing hardware conditions, successfully breaking through the limitations of hardware performance and bringing higher quality EVA shoe mold printing results to the footwear manufacturing industry, promoting the development of footwear manufacturing towards a more innovative and efficient direction.