“Snow Shadow” UAV Ski Helmet Model Case Study

2025-04-22

3D Printing-Headphone Case Study

2025-04-233D Printing - Car Grille Case Study

Product name: car grille

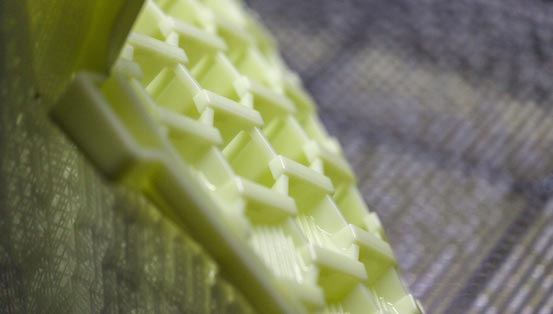

Process: rapid prototyping + polishing

Use: design, structural verification, vacuum casting prototype

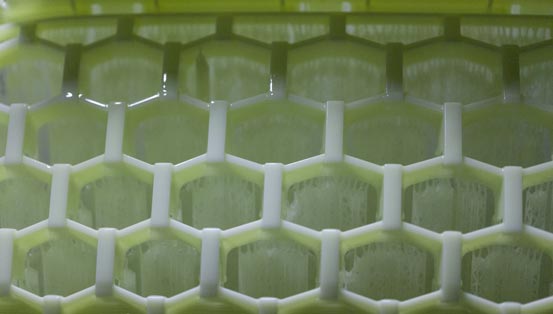

Car grille, also known as the "front face" and "ghost face" of the car, plays an important role in car design. In the car, the grille mainly plays an important role in the air intake ventilation of the water tank, engine, air conditioner, etc. It can prevent external objects from damaging the interior of the car during driving, and also show beauty and personality. Today, we will introduce how HXC directly applies 3D printing technology to the overall solution of the car to achieve innovation in the manufacturing mode of automotive parts.

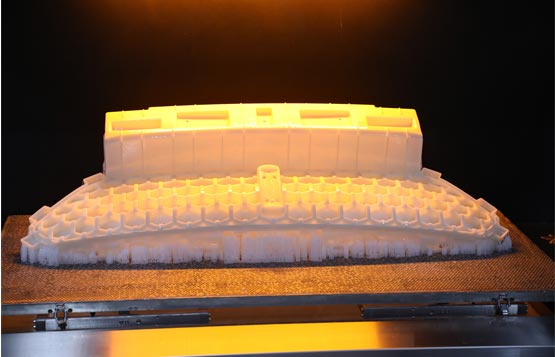

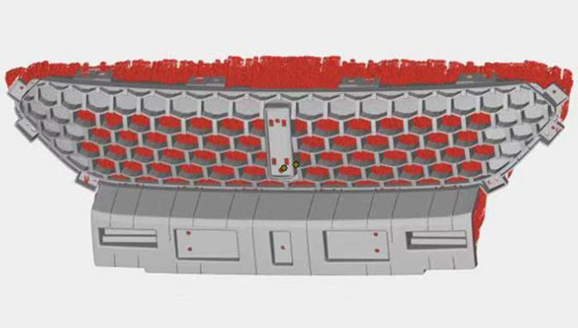

The structure of the grille is very complex. Without a mold, it would be difficult to develop it in the early stages and almost impossible to implement it. However, HXC's solution can be printed and implemented in one go.

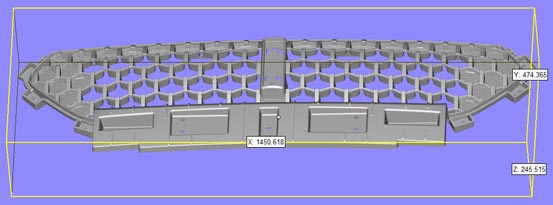

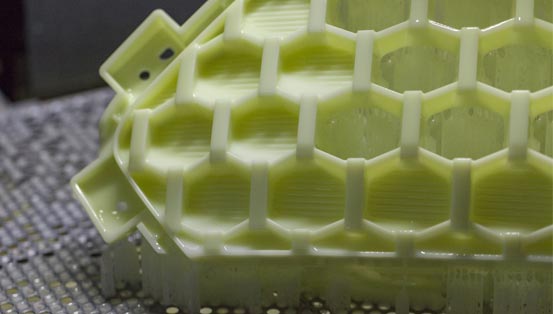

Grille size

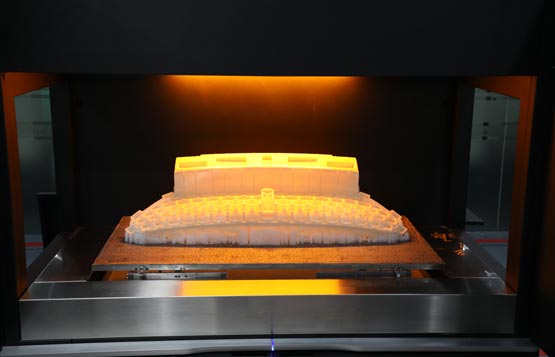

This 3D printed car grille is 1.45 meters long and uses post-processing technologies such as grinding and painting, with an error of less than 1mm. With exquisite craftsmanship, the entire production process is completed in 3 days. Compared with traditional processes, the development cycle is shortened by 80%, saving 70% of labor costs and 49% of production costs. This model can print large products such as car grilles, dashboards, bumpers, aircraft engines, real estate models, etc., which can effectively reduce errors and labor waste caused by splicing, and greatly improve product development efficiency.

Excellent printing material performance

This car grille is made of photosensitive resin (can be connected with material page). It has the characteristics of high temperature resistance, high strength, dimensional stability and chemical stability. It has faster molding speed and good surface finish, perfect molding details, high precision, easy to carry out various post-processing, very suitable for precision assembly of automotive, aerospace parts.

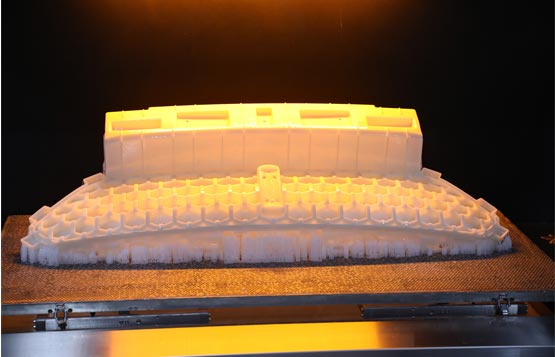

Finished product:

in conclusion:

The large-size printing format provides a reliable and low-cost 3D printing solution for the automotive, aerospace and other industries. With the excellent performance of the equipment and printing materials, the prototype production cycle of parts is greatly shortened, thereby shortening the part development cycle. Breaking through the limitations of printing size, it will become faster, more flexible and more economical in the manufacture of automotive parts.