Tracheal model cervical spine surgery simulation project

2025-04-21

3D Printing – Car Grille Case Study

2025-04-233D Printing Rapid Prototyping-"Snow Shadow" UAV Ski Helmet Model Case Analysis

Model name: "Xueying" UAV ski helmet

Material: photosensitive resin

Production process: SLA laser curing

Molding delivery cycle: 3 days

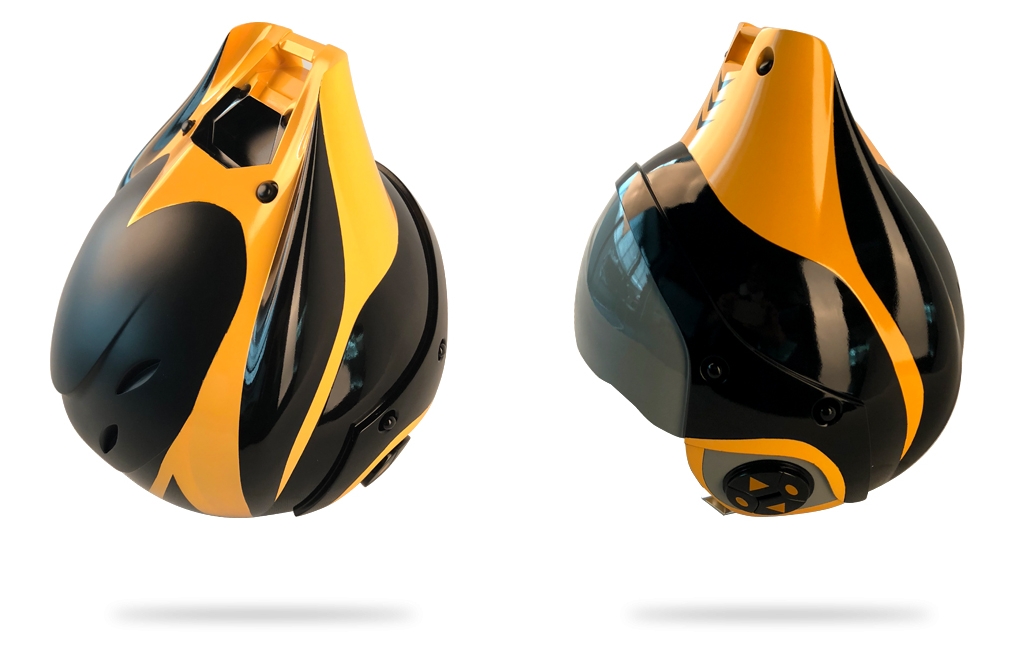

User requirements: prominent lines, uniform coloring, clear color separation, stylish and cool appearance

Project Background

Design Concept

As a skiing companion, "Xueying" is a good helper for skiing enthusiasts. As an extreme sport with full charm, skiing has certain risks, so good safety protection is required. "Xueying" provides users with GPS tracking and positioning services. Once the user falls, gets injured or gets lost outdoors, it will immediately notify the rescue station and safety center. Not only that, "Xueying" comes with a high-speed sports camera that can help users record the wonderful moments of skiing. The biggest highlight of "Xueying" is that it combines the take-off and landing of the drone with the ski helmet. When not in use, the drone is stored in the ski helmet, which is easy to carry.

Project Analysis

Processing Challenges

The post-processing of the model, grinding and painting, is very critical, which will affect the overall effect of the final model. Since the helmet designed by the customer has clear and three-dimensional lines, light and dark lines are crisscrossed, and the color matching is complex, consisting of four colors: matte black, glossy black, glossy orange, and metallic dark gray, this requires extremely high professional post-processing technology from our operators. When grinding, we must pay attention to the clear lines of the helmet model, and when painting, we must pay attention to clear color separation.

Solution

Since the model can be directly formed in one piece, we only need to ask our professional printer operator to add necessary supports to the model in the 3D printing slicer software. Reasonable addition of supports can increase the stability of printing, avoid any collapse of the pot, and also help the printing accuracy. After the support is done, it can be printed on the machine, which greatly reduces the production time.

After 3D printing, professional post-processing is the top priority of this project.

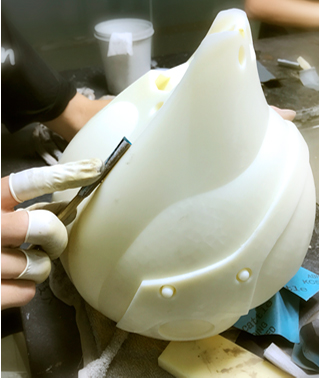

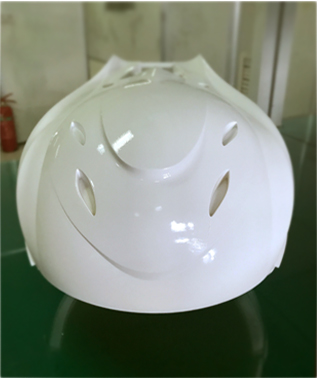

After the 3D printer is finished, we carefully remove the model from the platform and clean it with alcohol to prevent any liquid resin residue. Next, we need to remove the support. After our careful post-processing, all the extra supports have been perfectly removed. The following picture shows the printed model with the support removed.

Complex finishing

Once the print was finished, we carefully removed the model and cleaned it with alcohol. This was to remove any liquid material that may have been left behind during the printing process. Next, we had to remove the supports. This had to be done very carefully so as not to leave any marks on the final model. Below is the model with all the supports removed.

Sanding and painting are carried out alternately

The surface of the printed model is relatively rough, and some of the lines are still clearly visible. We polished it with sandpaper from coarse to fine (400-1500) until the surface was smooth. The helmet model of this project has clear three-dimensional lines and crisscrossing light and dark lines. We must be very careful and cautious during the polishing process to prevent the line from collapsing and causing poor shape. We demand perfection in details, and the polishing and painting processes are complicated and need to be carried out alternately. In order to make the overall appearance of the model look more perfect, we polished and sprayed the paint alternately three times, striving to make the primer color more even.

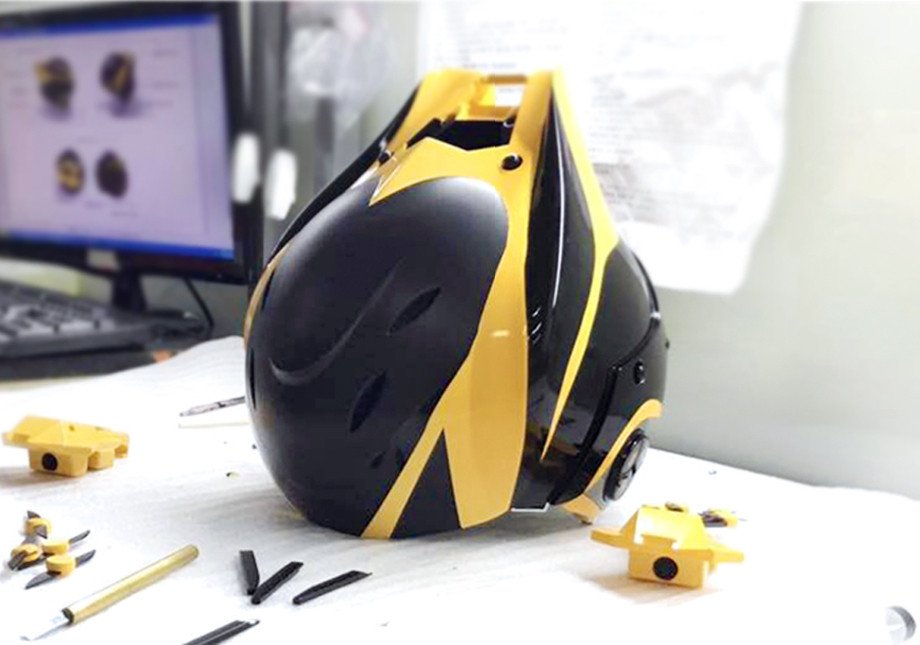

According to the customer's post-processing requirements, we need to spray the helmet with the corresponding paint color. This process is an important stage of post-processing and determines the final overall effect of the model. This requires our spray painters to have skilled techniques to prevent paint color collision or uneven coloring. The following picture shows our professional post-processing master carefully checking the color card according to the customer's specified color number requirements to confirm the paint color map and the spray painting color map.

Spray varnish

According to the customer's post-processing requirements, we need to spray the helmet with the corresponding paint color. This process is an important stage of post-processing and determines the final overall effect of the model. This requires our spray painters to have skilled techniques to prevent paint color collision or uneven coloring. The following picture shows our professional post-processing master carefully checking the color card according to the customer's specified color number requirements to confirm the paint color map and the spray painting color map.

Polishing

After spraying the varnish and letting it dry, we still need to perform a final polishing process on the local fine particles to achieve the best effect of the model.

Assembly

Final product

This project took 3 days from start to finish. By using our industry-leading 3D printer equipment and professional laser curing rapid prototyping technology, coupled with our skilled post-processing technical team, we completed the project perfectly and efficiently. Whether in production time or consumables, we have greatly saved costs for our customers. The printed models have achieved the best results in terms of accuracy or post-processing. If you have similar 3D printing service projects, please feel free to contact us!