Precision and accuracy in machining: the main difference

2024-10-26

Precision and accuracy in machining: the main difference

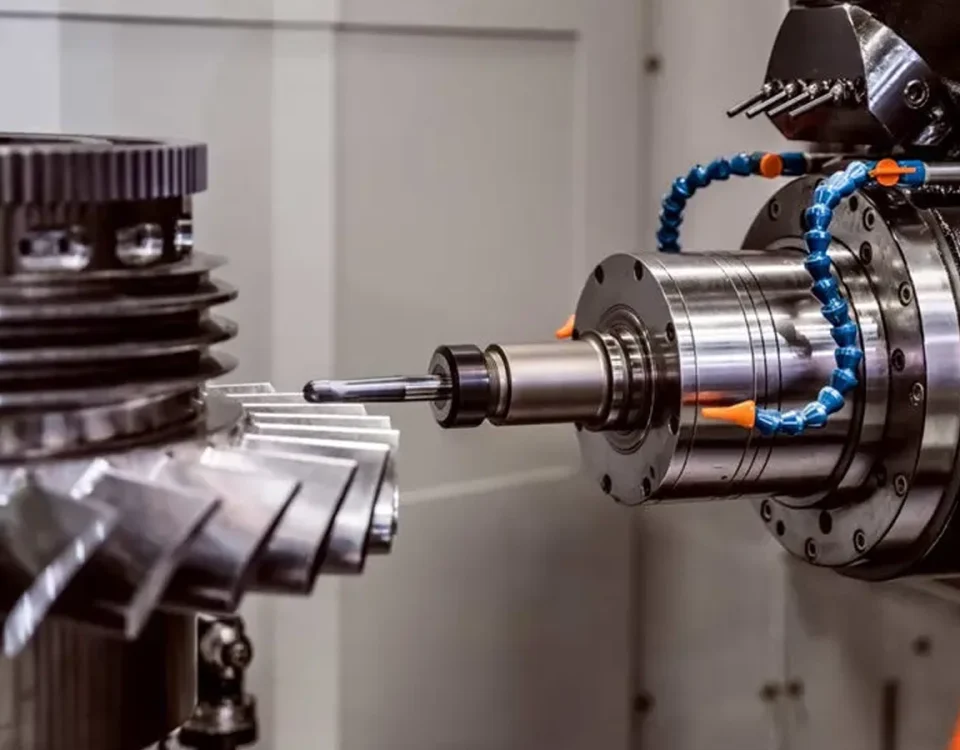

2024-10-26How to know whether the machined parts are precise and accurate? Different checks and measurements are used to ensure this. However, the concepts of accuracy and precision must first be understood.

They are mainly concerned with the correctness and repeatability of dimensioning, which is crucial for the overall quality of machining CNC parts and products. Although they are independent of each other, their overall measure determines the precision or functionality of the part. This article will discuss the differences between accuracy and precision and detail how these differences can be implemented to achieve the desired results.

Let’s get started!

What is the precision of machining?

The term “precision” refers to the closeness between the results of the machining measurements. It implies the repeatability of values across multiple trials. For example, if you read the diameter of the shaft at 6 mm, 6.01 mm, 6 mm, and 6.02 mm in three consecutive measurements, it can be said to be very accurate. However, precision has two important aspects in machining: repeatability and reproducibility.

Repeatability refers to the consistency of parts in a particular machining process or operation. For example, a milling machine setup creates multiple batches with the same characteristics, dimensions, and surface finish.

Repeatability refers to the proximity of parts converted from the same design but different machines, Settings and tools. This means parts won’t deviate from each other even if tools or other Settings change. For example, custom CAD models can be converted to size-close physical parts using milling and turning machining.

Therefore, precision machining = repeatability + reproducibility

What is precision in machining?

How close the measurement results are to the actual value. If the measurement result is the same as the theoretical value (the true value), the measurement result is completely accurate.

Secondly, machining accuracy refers to the closeness of dimensions or other properties to the initial set point CNC加工设计。It has three key components: bias, stability, and linearity.

| Aspects of | Definition | The importance of machining accuracy |

| 偏见 | 测量值与真实值/参考值之间的差异(系统误差)。 | 它通过最小化固定偏差来确保测量的准确性。 |

| 稳定性 | 随时间推移测量的一致性。 | 它可以防止因环境变化、工具磨损等原因造成的变化。 |

| 线性度 | 整个操作范围内测量误差的一致性。 | 它可确保不同零件尺寸和规格的结果准确。 |

Therefore, machining accuracy is not only about reaching the target value, but also about ensuring that the process remains unbiased, stable and linear under all operating conditions.

The main difference between precision and accuracy

Next, let us objectively compare precision and accuracy from three different aspects; Their definition, type of error, and measurement.

Different definitions

Precision is the closeness between a set of measurements. Therefore, the closer the values are, the higher the precision will be. Accuracy is how close the measured value is to the true value or reference value.

Error type classification

Systematic error and random error are two types of error, random error is related to accuracy, and systematic error is related to accuracy.

Random error

These are errors due to unpredictable reasons and the measurements show only fluctuations. This is a limitation of the measuring instrument or technique. For example, the capabilities of CNC technology itself place some limitations on the accuracy of the dimensions mentioned in the drawings.

Systematic errors

Systematic errors are caused by temperature fluctuations, tool wear, misalignment, errors in G and M codes, wrong Settings, and defects in measuring instruments. As the systematic error increases, the machining accuracy will decrease.

Quantity of measurement

High precision means that the measured data sets are very precise (values are close to each other). Thus, the standard deviation or variance quantifies the precision. Accuracy, on the other hand, involves the average of a single measurement or multiple measurements compared to a reference value.

Examples of typical precision and accuracy in machining

Although both accuracy and precision are related to measurement, they have different properties. Measurements can be made in any combination; Precise and accurate, accurate but not precise, etc. A popular example, throwing darts at a target, can illustrate the difference between precision and accuracy.

Let’s take an example 设计中提到的直径为 10 毫米的加工钢轴 Discuss typical scenarios where accuracy and precision are combined;

Precise and accurate

The gauges showed 10.00, 10.02, 10.01 and 10.00 mm, respectively. The diameters are close to the true value (10 mm) and close to each other, with a maximum variance of 0.02 mm.

Imprecise but accurate

The measured values were 10.01, 10.02, 9.98, 10.03, 9.99 and 10.01mm, respectively. These values are close to the reference value, 10mm, but are not close to each other. The maximum difference was 0.06mm.

Precise but not accurate

The measurements were 9.90, 9.91, 9.90, 9.91 and 9.92 mm, respectively. They are exact, the reason being that the data are close to each other but not to the true value of the diameter.

不精确也不准确

测量结果显示 9.90、9.86、9.95、9.79 和 9.80 毫米。这里,它们既不接近彼此,也不接近真实值(10 毫米)。这意味着这些值不精确且不准确。

零件生产中精度和准确度的重要性

制造过程中的精度有三个重要方面:功能性、性能和装配时的配合度。同时,精度对于多批次零件的一致性至关重要。

精密加工

它指的是生产具有高精度和重复性的机械零件。因此, 精密数控加工 使用各种仪器并测量准确度和精确度以确保所需的标准。

生产设备校准

制造过程中的任何系统性错误都表明机器、工具或检查精度的仪器存在缺陷。这就像重新校准制造和测量设备的通知。

减少材料浪费并提高可靠性

测量单个加工零件的精度有助于识别有缺陷的零件并立即调整制造流程。早期识别单个有缺陷的零件可以减少浪费。

零件组装

精确的零件对于更顺畅、更快速的装配过程至关重要。精确、准确的组件可以减少停机时间和人工成本。因此,生产线的整体效率会提高。

测量和检测加工零件的精度和准确度

测量系统

通常,加工零件采用两种类型的测量系统:尺寸测量和无尺寸测量。坐标测量机、量块、卡尺和 3D 激光扫描是测量尺寸特征的常用方法。另一方面,粗糙度测试、洛氏硬度测试和无损检测属于无尺寸测量。

关于检验,首件检验 (FAI) 是测量中最重要的因素。它通常涉及遵守标准和法规。例如,一般机械部件符合 ISO 9001 规定,航空航天部件符合 AS9100 规定。

测量系统分析

测量系统分析的目的是确定测量数据中的变化有多少来自系统本身,有多少是由于零件或过程造成的。

一些分析方法是;

- 稳定性: 多次试验的数据是否表明校准正确?

- 偏见:平均测量值与真实值有何区别?

- 线性度:在精确测量范围内,测量精度如何变化?

精密测量

它包括在相同条件下检查同一部件的重复测量,以通过重复性和加工再现性产生类似的结果。

- 重复性研究:同一操作员使用同一工具(千分尺或卡尺)测量同一部件的一致性。最小差异表示高重复性。

- 再现性研究:测试不同的 CNC 机械设置或操作员使用相同仪器是否产生类似的结果。

精度测量

准确度是指测量值与真实值的接近程度,而偏差、稳定性和线性是主要影响因素。精密测量仪器(如坐标测量机和卡尺)会获取数据,这些数据可用于计算。接下来,它通常以准确度的 % 表示;

准确度 = (测量值 – 真实值/真实值) x 100%

如何提高加工过程的精度和准确度?

设计阶段、机器能力、加工变量、设置和工具以及 数控加工 共同决定了整体的精度和准确度。因此,要提高它们,必须考虑很多因素。

减少人力投入、CAM和一致准确的零件。自动化操作,提高测量仪器的可靠性。

融入可制造性设计 (DFM) 原则

可制造性设计是指创建与高精度 CNC 机械能力完美匹配的 3D 模型,选择最佳材料,简化设计并遵循标准要求。例如,保持一致的 GD & T 并减少对工具访问造成挑战的复杂性。只有与现有机器和工具兼容的设计才能制造出精确而准确的零件。

- 选择平衡性能和成本的材料

- 创建与制造流程兼容的设计

- 考虑简化装配过程的因素。

- 标准化

确保设计符合严格的公差限制

在标注尺寸和公差时,请检查特定 CNC 机器的范围,并在加工图中相应地设置公差。在这里,确保标注的公差非常接近可实现的范围。例如,如果 CNC 铣床可以保持低至 ± 0. 13 毫米的公差,您可以在设计中将公差设置为更接近此值,即 ± 0. 125 毫米、± 0. 120 毫米等。同时,整个图纸中的公差也要统一。

优化加工切削参数

加工切削参数应根据工件材料、几何形状复杂程度和刀具类型进行选择。进给率、主轴转速、切削深度和冷却液流量等不同参数对精度和准确度的影响不同。例如,进给率对准确度的影响更大,而主轴转速对精度的影响很大。

CNC 编程是另一个因素。刀具路径和 G 和 M 代码 确定要加工的零件的最终尺寸。因此,在计算机软件中模拟刀具路径并对其进行优化,以实现高精度和准确的功能。

此外,加工工具的精度也会影响结果。任何工具磨损、轻微偏差或过热都可能导致许多缺陷,甚至彻底失败。

实施有效的夹具技术

有效的夹具不仅要固定工件和切削刀具,还要确保机床底座和机架的稳定性和刚性。精密夹具可以紧紧夹住工件,消除刀具移动、振动和错位误差。此外,设置夹具的操作员的经验也会影响精度。因此,夹具应由专业机械师设置。

以下是一些实施技巧;

- 使用定制和硬夹具进行批量生产

- 应用3-2-1工件定位原则

- 模块化夹具适用于原型设计和小批量

利用运动耦合实现一致对准

运动耦合的主要优点是它提供了出色的重复性并减少了互换性误差。此外,最小的接触点为动态加工过程提供了更高的运动自由度。运动耦合的另一个特点是对准与夹紧力无关。即使力发生变化,工件仍与刀具保持对准。此外,运动耦合还有助于精确控制工件上的刀具路径。