Our Manufacturing Servicesss

One stop solution

MODEL

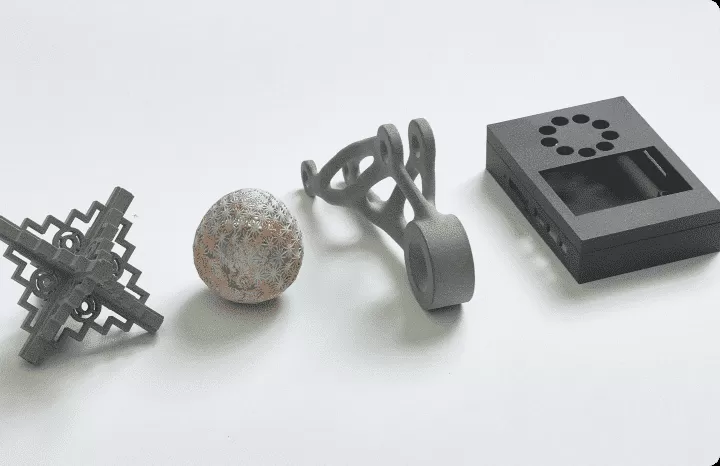

Rapid prototyping

We transform your ideas into realistic prototypes through 3D printing, vacuum casting, CNC machining and rapid injection molding. We can quickly test and verify the parts to help you smoothly go from concept to market and accelerate your product development.

PRODUCTION

Small and large batch production

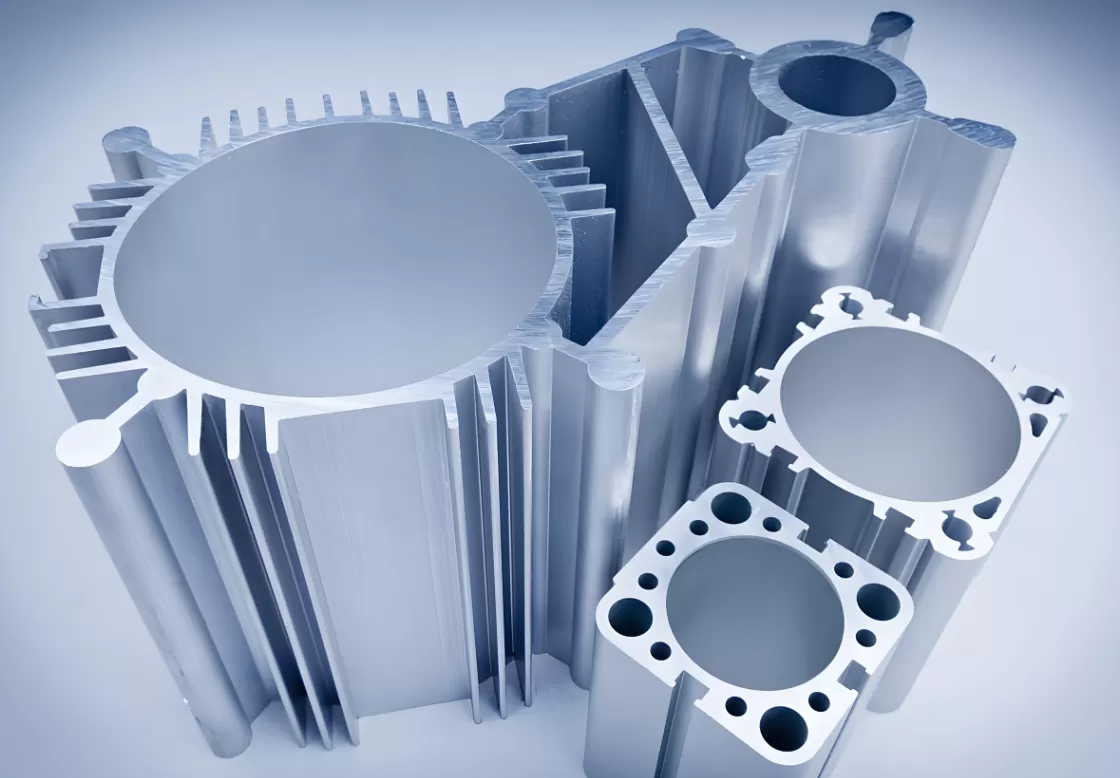

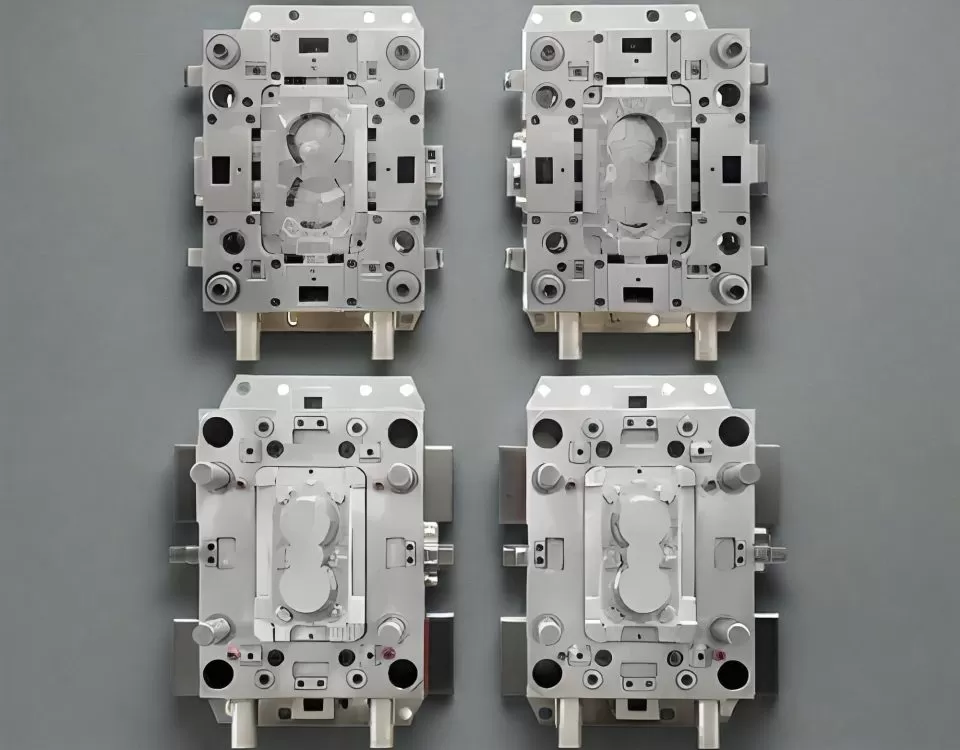

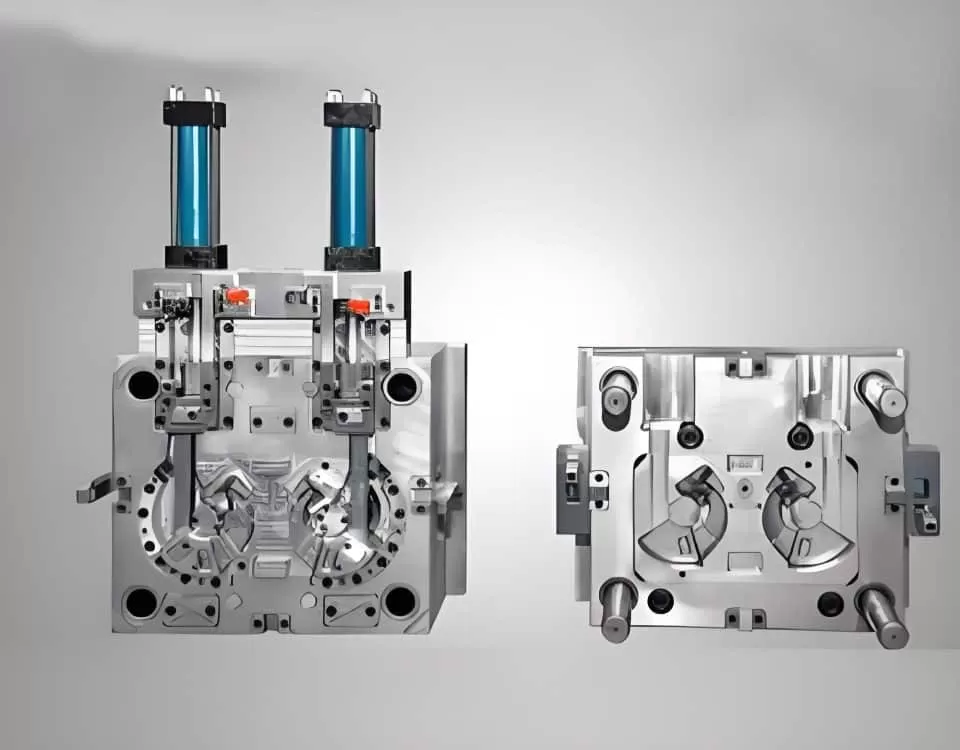

We are committed to turnkey projects. We use CNC machining, injection molding, die casting, stamping, extrusion, blow molding and other processes to achieve small to large batch production. Combined with our intelligent surface treatment facilities, we can fully ensure the consistency of your products. We also provide assembly and customized packaging services to make your products fast, efficient and stable production, so that you can focus on your product research and development.

Your Trusted Business Partners

Cool Project, Creative Unlimited

HXC prides itself on offering a higher level of customized service to meet your exact needs. Oursales engineering team supports you at every step, from initial product development through to mass production.

Countries and Regions

Serving customers

Cumulative manufactured parts

Self operated factory

Manufacturing base

precision equipment

WHY HXC

Choose the right rapid manufacturing service

-

HXC Precision was established in 2001 and has developed into a full-service, one-stop industrial manufacturing company serving global customers after over 20 years of development.

-

Our services include prototyping, CNC machining, mold manufacturing, injection molding, High-pressure die casting, casting, sheet metal , stamping, extrusion, product assembly, and various surface treatment options.

-

We have a strong engineering team, which includes a feasibility technical solutions team, a project management team, and a quality control team. They are ensure quality, delivery, and cost of our customers' projects. They approach each project from the customers' perspective and strive to help them succeed in a competitive market.

-

With robust production capacity supported by a scientific production management system, we operate over 300 CNC machines (3-axis, 4-axis, and 5-axis), 76 injection molding machines (single-color, two-color, and three-color), 45 extrusion, sheet metal, and stamping machines, and numerous imported inspection devices, including the German Weiss CMM and Japanese three-point CMM.

-

Our quality control is crucial in earning customer trust. We fully adopt the PPAP (Production Part Approval Process) to implement comprehensive quality management, allowing us to trace data throughout every production stage. Our quality management team focuses on monitoring production process and outcomes, promptly identifying defects to ensure that we do not send faulty products to our customers.

-

HXC's clients spans the globe. We recognize the importance of responsibility, integrity, and accountability in international dealings. Our commitment to service excellence fosters long-term relationships with clients. We treat customer's products as our own, which is key to HXC's ongoing industrial success.

Customer Reviews

Companies All Around The World TrustStar Rapid for awesome project creations

BOSCH

HXC has been involved in several of our important projects, and they are able to deliver a large number of projects simultaneously under higher pressure in a short period of time. Their support and commitment is important for the successful implementation of the SOP on time. We really like the team at HXC, and their support has allowed us to quickly reach the market.

BELA PETRO

Senior Project Buyer Bosch Lawn & Garden

SHOWPLA PLASTICS

HXC provides many tools to adapt the moulds of Showpla injection molding machines ranging from 50 tons to 1600 tons, and also supports me and my team in the marketing and trial organization in Asia. They manage our moulds and injection molding products in a scientific way, providing complete PPAP production procedures for each project. The HXC team is our reliable partner

IAN RICKUS

Technical Director SHOWPLA Plastics Ltd

ROYAL

PHILIPS

HXC's team enables them to creatively solve challenging problems and overcome problems that other companies have failed to solve.

They have worked with us for many years on pre-product project development, prototyping, injection molding, etc.

What impressed us most about HXC is that they are very focused on efficiency, integrity, and their ability to always think about their customers, and we are very honored to work with this team to produce popular products.

TOM CROWLEY

Philips Product Development Manager

TREND TECHNOLOGIES

"Trend Technologies have worked with hxc for over a decade. We value his expertise, trustworthiness and commitment to deliver projects to meet Quality, Time and Cost requirements."

Con Fallon

Global Tooling Manager Plastics Trend Technologies

Customer case

- Date

- 2024-10-15

- Date

- 2024-10-15

- Date

- 2024-10-15

- Date

- 2024-10-19