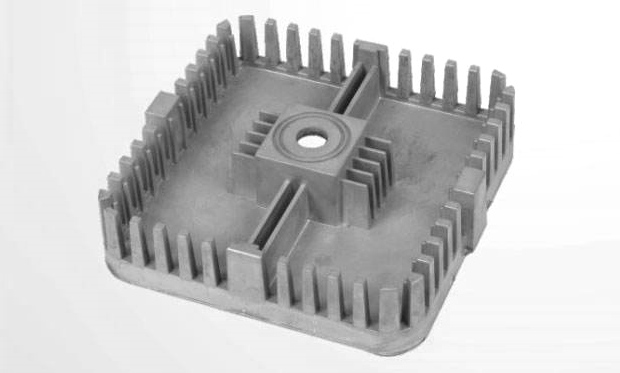

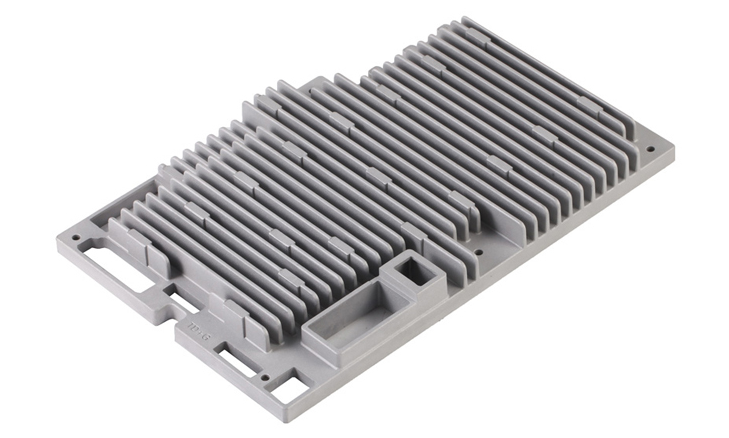

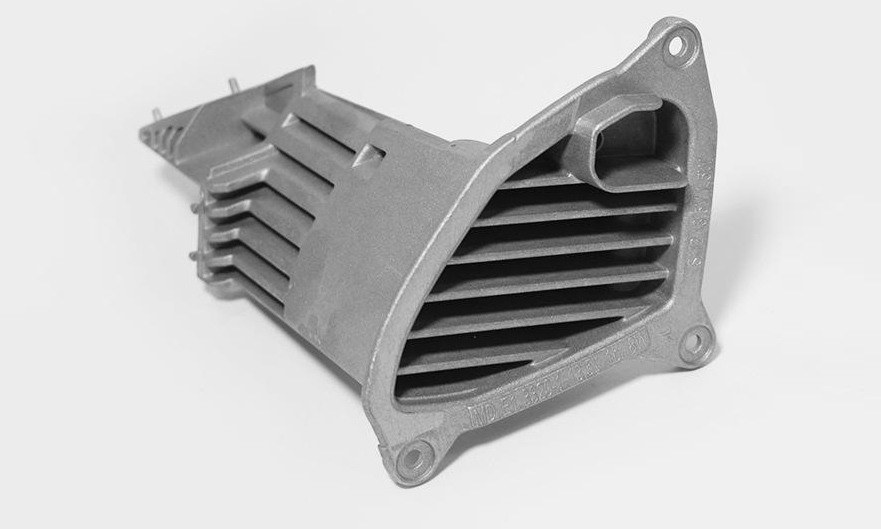

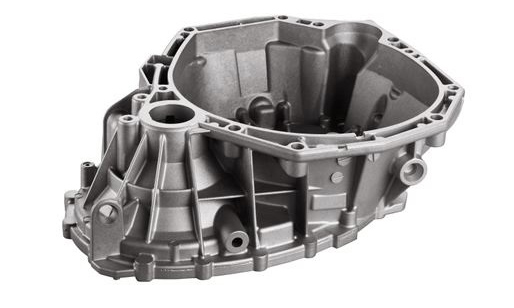

Aluminum die casting

Providing free design analysis and product quote

Consulting our die casting expertise team

High quality material supplier or material provided by customer

I will quote the best price for your aluminum alloy die casting project now

Properties of aluminum alloy

Excellent corrosion resistance

Excellent intensity and hardness

Excellent thermal conductivity and conductivity

Good stiffness and high weight ratio

Excellent shielding performance of EMI & RFI

One of the reasons is its high intensity.

Besides, its good corrosion resistance and great heat dispersion also make it a better choice.

Apart from that, we widen its application range again with our patents in aluminum die casting technology.

Contact us now and get project assessment for free!

Advanced Die Casting Manufacturing

Well designed SOP based on your design spec. (dimension,function,quality standard).

Well controlled of Incoming raw material quality

Advanced Die casting machine, automatically process

Well trained workers strictly operate acc to SOP

Die Casting Parts CNC Machining

Experienced engineer DFM the structure before tooling, CAM simulation the CNC route to ensure the allowance for post CNC machining.

Well designed CNC program to guarantee the the parts precision.

Based on your order quantity to choose the “smart” facility/technics to save your cost.

Responsible OQC will 100% inspect the parts, specially all the key dimension.

No worry about function, always 100% test before shipping.

In House Surface Treatment

Main reasons:

1、Liquidity shortage of molten aluminum, molten aluminum contains high air content, has more oxide skin.

2.Poor gating system, too small gate section.

3.Poor venting, too much coating, or too high mould temperature making air hard to vent.

Solutions:

1.Increase the liquidity of molten aluminum, appropriately increase gating temperature, mould temperature and gating speed.

2.Increase gating section acreage.

3.Improve venting conditions, add material chute and venting plug etc.

Powder coating is a dry coating process used as a metal finish. It is applied as dry powder through an electrostatic process, then cured with heat. …

Spray painting is a way of using the spray gun to use the air pressure, to generate uniform and fine fog droplets, and apply to the surface of the coated surface.

Aluminum anodizing is an electrochemical process that converts aluminum into aluminum oxide at the surface of the casting to improve the natural corrosion resistance.

a type of print made with a stencil and a fine mesh screen. Ink is applied to and forced through the small holes in the screen leaving the covered area free from ink.

Learn More About Surface Treament

Learn More About Surface Treament

Learn More About Surface Treament

Learn More About Surface Treament

Learn More About Surface Treament